Description

Product Overview

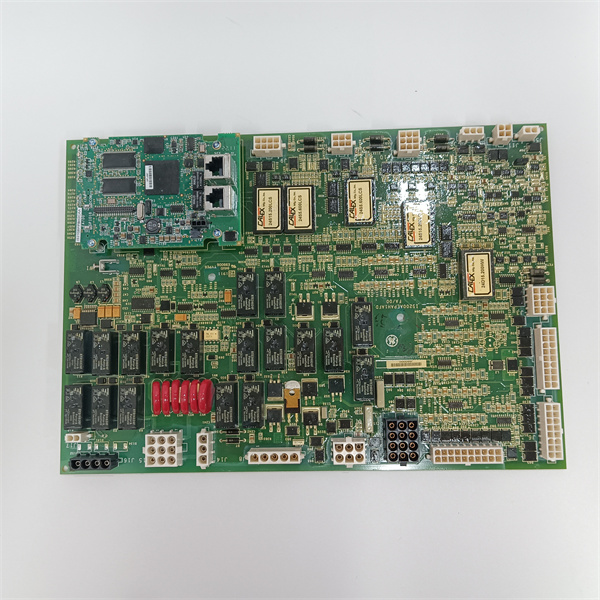

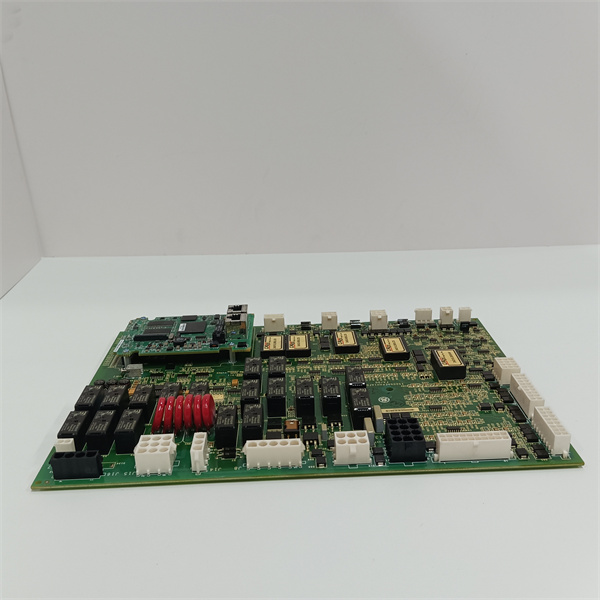

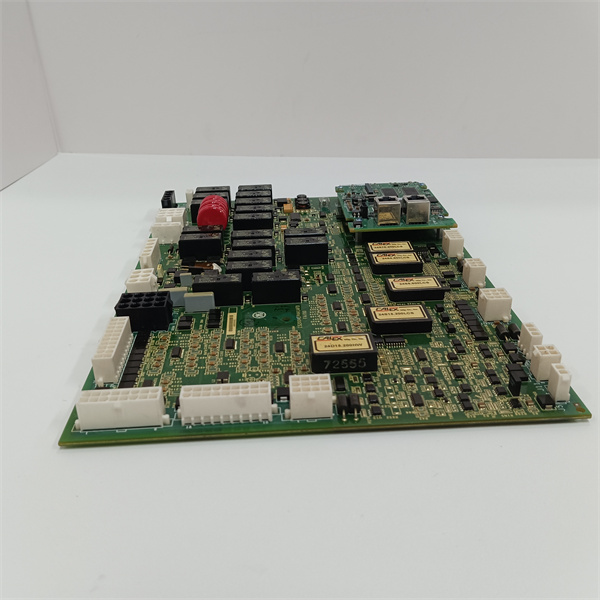

The GE IS210BPPCH1AEC is a high – performance programmable logic controller (PLC) CPU board by General Electric, meticulously engineered for industrial automation applications. As a core component in industrial control systems, it offers a compact yet powerful solution, enabling seamless operation and control within complex industrial setups.

Powered by a 32 – bit ARM Cortex – M4 processor, the IS210BPPCH1AEC delivers outstanding processing capabilities, making it well – equipped to handle the most demanding industrial tasks. It can efficiently execute control algorithms and manage data flow, ensuring smooth operation of industrial processes. This board also exhibits remarkable flexibility in terms of input/output (I/O) functionality. It can be paired with a diverse range of I/O modules, such as digital inputs and outputs, analog inputs and outputs, and special function modules. This adaptability allows the PLC to be easily customized to suit various industrial scenarios, from simple manufacturing processes to intricate power generation operations.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS210BPPCH1AEC |

| Manufacturer | General Electric |

| Product Type | PLC CPU Board |

| Processor | 32 – bit ARM Cortex – M4 processor |

| Memory | 128kb RAM, 512 kb ROM |

| Communication | Ethernet, Modbus RTU, Modbus TCP/IP |

| Operating Temperature | – 25 °C to + 70 °C |

| Storage Temperature | – 40 °C to + 85 °C |

| Input/Output Compatibility | Compatible with digital, analog, and special function I/O modules |

| Mounting Method | Designed for easy installation in industrial enclosures |

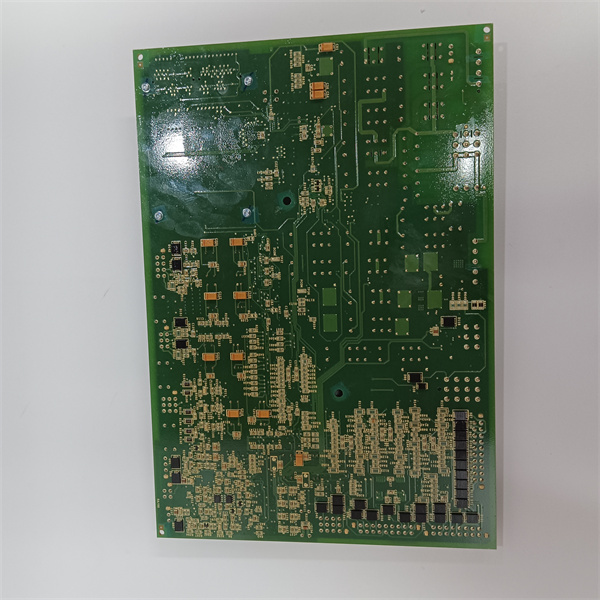

| Dimensions | Compact design for space – constrained installations |

| Weight | Lightweight for convenient handling during installation |

| Certifications | Meets relevant industrial standards for quality and safety |

IS210BPPBH2CAA

Main Features and Advantages

High – Performance Processing

The 32 – bit ARM Cortex – M4 processor empowers the IS210BPPCH1AEC with high – speed data processing. This enables quick response times to input signals and rapid execution of control commands. In fast – paced manufacturing lines, for example, the board can swiftly process sensor data and trigger appropriate actions, enhancing production efficiency and minimizing downtime.

Flexible I/O Configuration

With its compatibility with a wide array of I/O modules, the IS210BPPCH1AEC offers great flexibility. Industries with diverse control requirements can mix and match different I/O modules according to their specific needs. For instance, in a chemical plant, it can interface with analog sensors for process variable monitoring and digital actuators for valve control.

Easy Programming

The board supports multiple programming languages, including ladder logic, function block diagram, and structured text. This accessibility allows programmers with different backgrounds and preferences to easily code the PLC to meet unique industrial requirements. Whether it’s a novice engineer or an experienced programmer, they can find a suitable language to program the IS210BPPCH1AEC effectively.

Rugged Construction

Built to withstand harsh industrial environments, the IS210BPPCH1AEC has a rugged construction. It can endure temperature variations, humidity, and electromagnetic interference commonly found in industrial settings. This makes it reliable for use in factories, power plants, and mining operations, where consistent performance is crucial.

Compact Design

Its compact form factor is an advantage in installations where space is limited. Control cabinets in industrial facilities often have restricted space, and the IS210BPPCH1AEC‘s small footprint allows for efficient use of available space without sacrificing functionality.

IS210BPPBH2CAA

Application Field

In manufacturing industries, the GE IS210BPPCH1AEC plays a pivotal role. It can control the operation of automated production lines, such as regulating the movement of robotic arms in automotive manufacturing. The board can precisely process sensor feedback to ensure accurate part handling and assembly, improving product quality and production speed.

Power generation plants rely on the IS210BPPCH1AEC for controlling and monitoring power – generation equipment. It can manage the operation of turbines, generators, and associated systems. By processing data from various sensors, it can adjust equipment parameters in real – time to optimize power generation efficiency and ensure stable power supply.

In the oil and gas industry, the board is used in remote terminal units (RTUs) for controlling and monitoring equipment in challenging environments. It can control the opening and closing of valves in pipelines, monitor pressure and temperature sensors, and communicate data back to a central control station. The IS210BPPCH1AEC‘s reliability and flexibility make it an ideal choice for such critical applications.

Related Products

- IS210BPPCH1AC: Similar to the IS210BPPCH1AEC, it is an I/O pack processor board for the Mark VIe speedtronic system. However, it might have differences in specific features or compatibility with certain system configurations. It could be an alternative for users with slightly different requirements within the Mark VIe system setup.

- IC200CPU001: Another CPU module by GE but from a different product line. While the IS210BPPCH1AEC is designed for specific industrial automation applications with its ARM Cortex – M4 processor and particular I/O flexibility, the IC200CPU001 may have different processing capabilities and be better suited for other types of industrial control systems or legacy setups.

- IS200ACLEH1ACB: This is likely an interface or control – related board. It can be used in combination with the IS210BPPCH1AEC in a larger industrial control system. For example, it might handle specific communication interfaces or perform additional control functions that complement the main processing and I/O capabilities of the IS210BPPCH1AEC.

- IS215ACLEH1BC: Similar to the above, it could be a module that interfaces with the IS210BPPCH1AEC in an industrial network. It may have different communication protocols or signal – handling capabilities that help in integrating the IS210BPPCH1AEC – based system with other components in a complex industrial automation environment.

- IS220PDOAH1A: This might be an output – focused module. It can work in tandem with the IS210BPPCH1AEC, where the IS210BPPCH1AEC processes the control logic and sends commands to the IS220PDOAH1A to execute specific output functions, such as driving actuators or relays in an industrial process.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS210BPPCH1AEC, carefully check the power supply to ensure it meets the board’s requirements. The installation environment should be clean, free from dust, and within the specified operating temperature range of – 25 °C to + 70 °C. Verify the compatibility of the IS210BPPCH1AEC with other components in the system, including I/O modules, communication cables, and power supplies. Make sure to have the appropriate tools for installation, such as screwdrivers for mounting the board in the control cabinet. Also, check the integrity of the board for any visible damage during transportation.

Maintenance recommendations: Regularly inspect the IS210BPPCH1AEC for any signs of physical damage, such as cracks on the circuit board or loose connections. Monitor its operating temperature and humidity levels to ensure they remain within the specified ranges. Clean the board periodically to remove dust that can accumulate over time and affect its performance. Check the communication status of the board through Ethernet or Modbus interfaces to ensure there are no data transfer issues. If any problems are detected, refer to the product manual for troubleshooting steps or contact GE’s technical support team for assistance. Periodically update the firmware of the board to take advantage of the latest features and improvements.

Product Guarantee

GE offers a comprehensive product guarantee for the IS210BPPCH1AEC. The company ensures that the board is free from defects in materials and workmanship. In case of any quality – related issues during the warranty period, GE provides prompt repair or replacement services. Their team of experienced technicians is available to offer technical support, helping customers with installation, configuration, and maintenance queries. GE’s long – standing reputation for reliability in the industrial automation field gives customers confidence in the performance of the IS210BPPCH1AEC. The company’s commitment to customer satisfaction is reflected in its after – sales service, making the IS210BPPCH1AEC a reliable choice for industrial applications.