Description

Product Overview

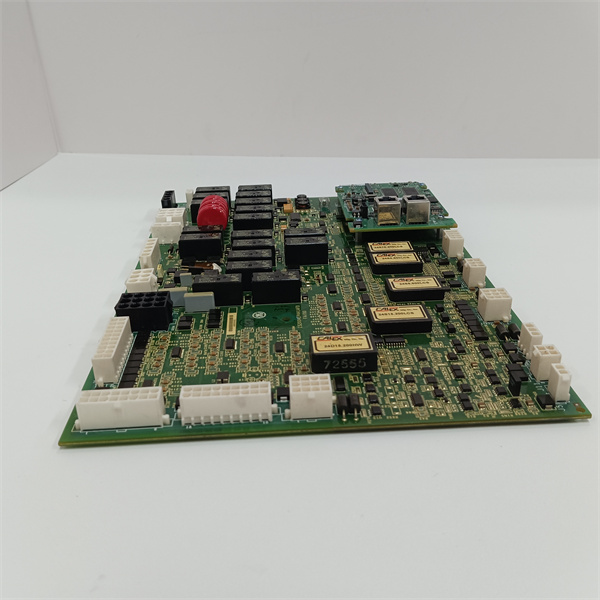

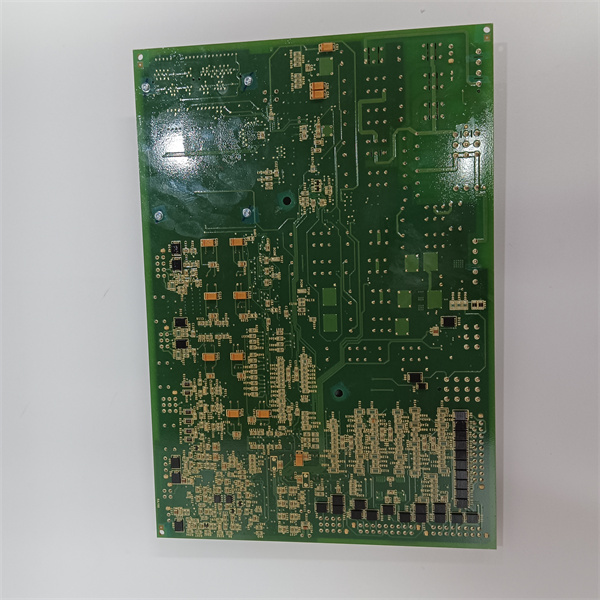

The GE IS210BPPBH2CAA is a pivotal printed circuit board within the illustrious GE Mark VI series control system. Engineered with precision, this board is designed to play a crucial role in the management and control of both gas and steam turbines, making it an indispensable asset across a wide spectrum of industrial applications.

In industrial settings, especially those related to power generation and large – scale manufacturing, the GE IS210BPPBH2CAA acts as a nerve center. It interfaces with multiple components within the turbine control system, ensuring seamless data flow and accurate control commands. By collecting real – time data from sensors monitoring various turbine parameters such as temperature, pressure, and rotational speed, it processes this information and executes control algorithms to optimize turbine performance. Whether it’s maintaining stable power output in a power plant or ensuring efficient operation of industrial turbines in a manufacturing facility, the IS210BPPBH2CAA is at the heart of reliable and efficient turbine control.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS210BPPBH2CAA |

| Manufacturer | GE |

| Product Type | Printed Circuit Board |

| Humidity Range | 5 – 95 % non – condensing |

| Weight | Less than 2 pounds (approx. 310g) |

| Prime Mover Types | Gas / Steam Turbine |

| Series | Mark VI |

| Operating Temperature Range | – 40 °C to + 70 °C |

| Processor | High – speed for real – time control and data processing |

| Memory | Adequate for extensive control algorithms and data storage |

| Input/Output Capacity | Supports multiple I/O channels for comprehensive control |

| Communication Interfaces | Multiple ports, supporting standard industrial protocols |

| Power Supply | Operates with standard industrial power supplies |

IS210BPPBH2CAA

Main Features and Advantages

High – Precision Control: The GE IS210BPPBH2CAA offers high – precision control capabilities for gas and steam turbines. It can precisely regulate turbine operations, which is crucial for maintaining optimal performance. This results in enhanced efficiency, reduced fuel consumption, and extended equipment lifespan. For example, it can accurately adjust the fuel – air mixture in a gas turbine based on real – time operating conditions, ensuring efficient combustion.

Robust Construction: Built to withstand the harsh environments of industrial settings, this board has a robust construction. It can endure temperature fluctuations, electrical noise, and mechanical vibrations. With an operating temperature range of – 40 °C to + 70 °C and resistance to humidity levels from 5 – 95 % non – condensing, it ensures long – term durability and consistent performance, minimizing the risk of unexpected failures.

Seamless System Integration: As an integral part of the GE Mark VI control system, the IS210BPPBH2CAA seamlessly integrates with other components within the system. This integration allows for smooth communication and coordination between different parts of the turbine control setup, enhancing overall system performance and compatibility. It can easily interface with sensors, actuators, and other control modules, creating a unified and efficient control ecosystem.

Advanced Monitoring and Diagnostics: Equipped with advanced monitoring features, the board enables real – time diagnostics of turbine operations. It can detect early signs of potential issues, such as abnormal temperature rises or vibration patterns. This allows for proactive maintenance, reducing unplanned downtime and associated costs. For instance, it can continuously monitor the health of critical turbine components and alert operators when maintenance is required.

Robust Construction: Built to withstand the harsh environments of industrial settings, this board has a robust construction. It can endure temperature fluctuations, electrical noise, and mechanical vibrations. With an operating temperature range of – 40 °C to + 70 °C and resistance to humidity levels from 5 – 95 % non – condensing, it ensures long – term durability and consistent performance, minimizing the risk of unexpected failures.

Seamless System Integration: As an integral part of the GE Mark VI control system, the IS210BPPBH2CAA seamlessly integrates with other components within the system. This integration allows for smooth communication and coordination between different parts of the turbine control setup, enhancing overall system performance and compatibility. It can easily interface with sensors, actuators, and other control modules, creating a unified and efficient control ecosystem.

Advanced Monitoring and Diagnostics: Equipped with advanced monitoring features, the board enables real – time diagnostics of turbine operations. It can detect early signs of potential issues, such as abnormal temperature rises or vibration patterns. This allows for proactive maintenance, reducing unplanned downtime and associated costs. For instance, it can continuously monitor the health of critical turbine components and alert operators when maintenance is required.

Application Field

Power Generation: In power plants, the GE IS210BPPBH2CAA is extensively used in the control of both gas – fired and steam – powered turbines. It ensures stable power generation by precisely controlling turbine speed, load, and other critical parameters. For example, in a combined – cycle power plant, it coordinates the operation of the gas turbine and steam turbine to optimize power output and efficiency. It also plays a vital role in protecting turbine equipment from over – load, over – speed, and other potentially damaging conditions.

Industrial Manufacturing: In large – scale manufacturing industries, such as petrochemicals and steel production, turbines are used for various purposes, including powering compressors and pumps. The IS210BPPBH2CAA is employed to control these turbines, ensuring smooth operation of the manufacturing processes. It can adjust turbine performance based on the changing demands of the production line, such as regulating the speed of a compressor to maintain a consistent pressure in a petrochemical plant.

Marine Applications: In marine vessels, especially those powered by gas or steam turbines, the GE IS210BPPBH2CAA is used for turbine control. It helps in managing the ship’s power generation system and propulsion turbines. By providing accurate control, it ensures safe and efficient navigation, while also enabling optimal fuel consumption, which is crucial for long – distance voyages.

Industrial Manufacturing: In large – scale manufacturing industries, such as petrochemicals and steel production, turbines are used for various purposes, including powering compressors and pumps. The IS210BPPBH2CAA is employed to control these turbines, ensuring smooth operation of the manufacturing processes. It can adjust turbine performance based on the changing demands of the production line, such as regulating the speed of a compressor to maintain a consistent pressure in a petrochemical plant.

Marine Applications: In marine vessels, especially those powered by gas or steam turbines, the GE IS210BPPBH2CAA is used for turbine control. It helps in managing the ship’s power generation system and propulsion turbines. By providing accurate control, it ensures safe and efficient navigation, while also enabling optimal fuel consumption, which is crucial for long – distance voyages.

IS210BPPBH2CAA

Related Products

GE IS210BPPCH1AD: Likely part of the same Mark VI series. It may have similar functions but could differ in specific technical aspects. For example, it might have a different I/O configuration or be optimized for a slightly different set of turbine applications compared to the IS210BPPBH2CAA.

GE IS420YAICS1B: A high – performance module with capabilities like high – speed data processing. In a turbine control system, it could work in tandem with the IS210BPPBH2CAA, with the former handling certain types of data processing tasks while the IS210BPPBH2CAA focuses on overall turbine control and interface with other components.

GE DS200TCEAG1BTF: This is an emergency – overspeed board in the GE Speedtronic MKV gas – turbine control system. In a larger turbine control setup, the IS210BPPBH2CAA might interact with it, with the DS200TCEAG1BTF handling emergency overspeed situations while the IS210BPPBH2CAA manages normal turbine operation and other control functions.

GE IC8008SI228RD2: Known for its high – reliability with industrial – grade components. It could be used in the same industrial environment as the IS210BPPBH2CAA, perhaps for tasks related to data storage or simple control functions that support the overall operation of the turbine control system where the IS210BPPBH2CAA is the main control board.

GE SR750 – P1 – G1 – S1 – H1 – A20 – G: With features like high – efficiency power conversion, it might be involved in providing power to the IS210BPPBH2CAA or other components in the turbine control system, ensuring stable and reliable power supply for the board’s operation.

GE IS420YAICS1B: A high – performance module with capabilities like high – speed data processing. In a turbine control system, it could work in tandem with the IS210BPPBH2CAA, with the former handling certain types of data processing tasks while the IS210BPPBH2CAA focuses on overall turbine control and interface with other components.

GE DS200TCEAG1BTF: This is an emergency – overspeed board in the GE Speedtronic MKV gas – turbine control system. In a larger turbine control setup, the IS210BPPBH2CAA might interact with it, with the DS200TCEAG1BTF handling emergency overspeed situations while the IS210BPPBH2CAA manages normal turbine operation and other control functions.

GE IC8008SI228RD2: Known for its high – reliability with industrial – grade components. It could be used in the same industrial environment as the IS210BPPBH2CAA, perhaps for tasks related to data storage or simple control functions that support the overall operation of the turbine control system where the IS210BPPBH2CAA is the main control board.

GE SR750 – P1 – G1 – S1 – H1 – A20 – G: With features like high – efficiency power conversion, it might be involved in providing power to the IS210BPPBH2CAA or other components in the turbine control system, ensuring stable and reliable power supply for the board’s operation.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS210BPPBH2CAA, ensure that all power sources in the turbine control system are turned off to avoid electrical hazards. Thoroughly inspect the board for any visible signs of damage during transit, such as bent pins or cracks on the circuit board. Verify the compatibility of the board with the existing Mark VI control system, especially in terms of power requirements, communication protocols, and mechanical mounting. Prepare the installation location, making sure it is clean, dry, and free from excessive dust or vibrations. Mounting the board in a proper enclosure that meets the environmental requirements specified for the IS210BPPBH2CAA is also essential.

Maintenance recommendations: Regularly monitor the performance of the IS210BPPBH2CAA by checking for any abnormal behavior in the turbine control system. Look for signs of overheating, such as unusual warmth or discoloration of the board. Periodically clean the board to remove dust and debris, as these can affect its electrical performance. Update the firmware of the board as recommended by GE to ensure it has the latest features and bug fixes. If any communication or control issues occur, check the integrity of the communication cables and the configured settings related to the board. Keep spare boards on hand to minimize downtime in case of a component failure.

Maintenance recommendations: Regularly monitor the performance of the IS210BPPBH2CAA by checking for any abnormal behavior in the turbine control system. Look for signs of overheating, such as unusual warmth or discoloration of the board. Periodically clean the board to remove dust and debris, as these can affect its electrical performance. Update the firmware of the board as recommended by GE to ensure it has the latest features and bug fixes. If any communication or control issues occur, check the integrity of the communication cables and the configured settings related to the board. Keep spare boards on hand to minimize downtime in case of a component failure.

Product Guarantee

GE stands firmly behind the quality of the IS210BPPBH2CAA. The board undergoes rigorous quality control procedures during manufacturing to meet high – industry standards. In case of any manufacturing defects, GE offers a comprehensive warranty, typically for a specified period, which may vary depending on the region and specific terms. Their global network of technical support teams is available to assist customers. Whether it’s providing guidance on installation, helping with troubleshooting complex issues, or offering advice on maintenance, GE’s experts are dedicated to ensuring the long – term, reliable operation of the IS210BPPBH2CAA. This reflects GE’s confidence in the product’s quality and their commitment to customer satisfaction, giving users peace of mind when integrating this board into their critical industrial systems.