Description

Product Overview

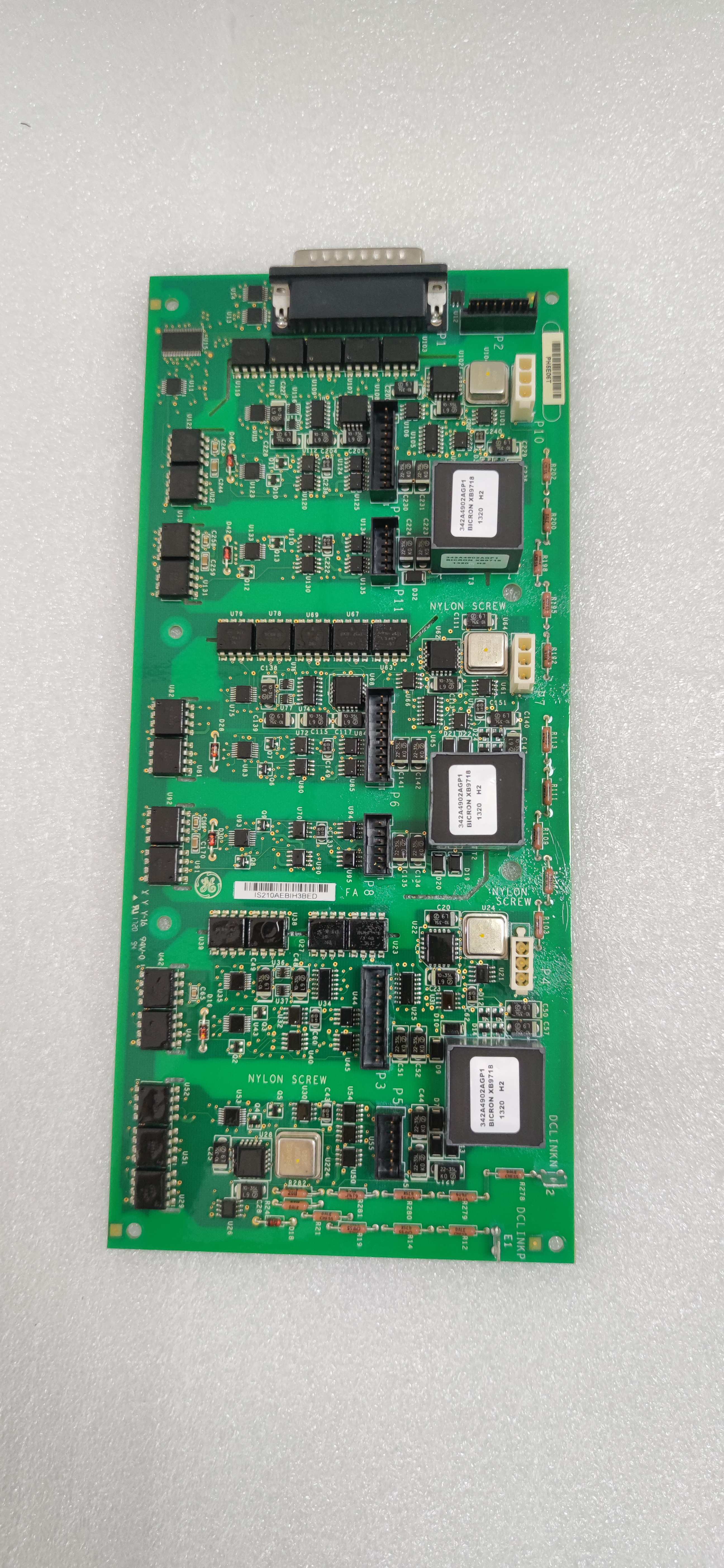

The GE IS210AEBIH1BED is a highly specialized communication interface module within GE’s industrial automation product portfolio. It is an integral part of the Mark VIe series, which is renowned for its advanced control and monitoring capabilities in industrial turbine systems. This module serves as a crucial link, enabling seamless communication between different components of the automation system, such as control units, I/O devices, and other modules.

The IS210AEBIH1BED is designed to handle high – speed data transfer, ensuring that real – time information can be efficiently exchanged across the industrial network. Its core function lies in providing reliable and accurate communication, which is essential for maintaining the stability and performance of industrial processes. Whether it’s in a power generation plant where precise control of turbines is required, or in a large – scale manufacturing facility with complex automation setups, the GE IS210AEBIH1BED plays a vital role in facilitating smooth operation and optimizing productivity.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS210AEBIH1BED |

| Manufacturer | General Electric |

| Product Type | Communication Interface Module |

| Communication Protocols | Ethernet, Modbus TCP/IP, Profibus DP |

| Data Transfer Rate | Up to 100 Mbps (Ethernet) |

| Input Voltage | 24 VDC |

| Power Consumption | 15 W |

| Operating Temperature Range | – 40 °C to + 70 °C |

| Humidity Range | 5% – 95% (non – condensing) |

| Dimensions | 150 mm x 100 mm x 50 mm |

| Weight | 0.8 kg |

| Certifications | CE, UL, CSA |

IS210AEBIH3BED

Main Features and Advantages

High – Speed Communication

The GE IS210AEBIH1BED supports data transfer rates of up to 100 Mbps over Ethernet, enabling rapid exchange of information between different parts of the industrial system. This high – speed communication is crucial for applications that require real – time monitoring and control, such as in high – speed manufacturing lines or power plants with dynamic load requirements.

Multiple Protocol Support

With support for Ethernet, Modbus TCP/IP, and Profibus DP, the module offers great flexibility in integrating with a wide range of industrial devices and systems. It can easily communicate with different types of sensors, actuators, and controllers, regardless of the communication protocol they use. This versatility reduces the need for multiple interface modules, simplifying the overall system design and reducing costs.

Robust and Reliable

Built to withstand harsh industrial environments, the IS210AEBIH1BED can operate within a wide temperature range of – 40 °C to + 70 °C and a humidity range of 5% – 95% (non – condensing). Its durable construction and high – quality components ensure reliable performance even in challenging conditions, minimizing the risk of system failures and downtime.

Compact Design

Despite its powerful functionality, the module has a compact design with dimensions of 150 mm x 100 mm x 50 mm and a weight of 0.8 kg. This makes it easy to install in control cabinets with limited space, providing flexibility in system layout and installation.

IS210AEBIH3BED

Application Field

In the power generation industry, the GE IS210AEBIH1BED is widely used in gas and steam turbine control systems. It enables seamless communication between the turbine control unit, sensors monitoring turbine parameters (such as speed, temperature, and pressure), and actuators controlling the turbine’s operation. This ensures that the turbines operate efficiently and safely, optimizing power generation and reducing fuel consumption.

In manufacturing plants, the module plays a key role in industrial automation systems. It can be used to connect different production line components, such as robotic arms, conveyor belts, and assembly machines, enabling coordinated operation and real – time monitoring. For example, in an automotive manufacturing plant, the IS210AEBIH1BED can facilitate communication between the control system and various sensors and actuators on the production line, ensuring smooth production flow and high – quality output.

The chemical industry also benefits from the IS210AEBIH1BED. In chemical plants, where precise control of chemical processes is essential, the module enables communication between different process control systems, monitoring devices, and safety systems. This helps in maintaining the stability of chemical reactions, ensuring product quality, and enhancing overall plant safety.

Related Products

- GE IS210AEBIH1AED: Similar to the IS210AEBIH1BED, it is also a communication interface module in the Mark VIe series. However, it may have some differences in specific features or configurations, such as slightly different communication protocol support or data transfer rate capabilities.

- GE IS210AEBIH2BED: Another variant in the same product line, it could offer enhanced functionality or additional features compared to the IS210AEBIH1BED. For example, it might have more communication ports or improved error – handling capabilities.

- GE IS215ACLEH1BC: A different type of module in the GE industrial automation product range, it could be used in conjunction with the IS210AEBIH1BED in a larger industrial control system. While the IS210AEBIH1BED focuses on communication, the IS215ACLEH1BC may handle other aspects of the system, such as data processing or control logic execution.

- GE IS200AEBIH1A: An older model in the GE communication interface module series, it may have lower performance or fewer features compared to the IS210AEBIH1BED. However, it could still be used in some legacy industrial systems or applications with less demanding communication requirements.

- GE IS220AEBIH1A: A potential successor or related product, it might incorporate the latest technological advancements and offer improved performance, reliability, and functionality over the IS210AEBIH1BED. It could be designed to meet the evolving needs of modern industrial automation systems.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS210AEBIH1BED, ensure that the power supply is stable and provides a 24 VDC output. The installation area should be clean, free from dust and debris, and within the specified operating temperature and humidity ranges. Check the compatibility of the module with other components in the system, including communication cables, control units, and I/O devices. Use proper electrostatic discharge (ESD) protection measures, such as wearing an ESD wrist strap, when handling the module to prevent damage to its sensitive electronic components.

Maintenance recommendations: Regularly inspect the IS210AEBIH1BED for any signs of physical damage, such as cracks on the circuit board or loose connections. Monitor its operating temperature and humidity levels to ensure they remain within the specified ranges. Clean the module periodically to remove dust that can accumulate over time and affect its performance. Check the communication status of the module regularly to ensure that data transfer is occurring smoothly and without errors. If any issues are detected, refer to the product manual for troubleshooting steps or contact GE’s technical support team for assistance. It is also advisable to keep the module’s firmware up – to – date to benefit from the latest bug fixes and performance improvements.

Product Guarantee

GE offers a comprehensive product guarantee for the GE IS210AEBIH1BED. The company ensures that the module is free from defects in materials and workmanship. In case of any quality – related issues during the warranty period, GE will provide prompt repair or replacement services. Their team of experienced technicians is available to offer technical support, helping customers with installation, configuration, and maintenance queries. GE’s commitment to quality and customer satisfaction is reflected in its after – sales service, which includes regular product updates and enhancements. This gives customers confidence in the reliability and long – term performance of the IS210AEBIH1BED in their industrial applications.