Description

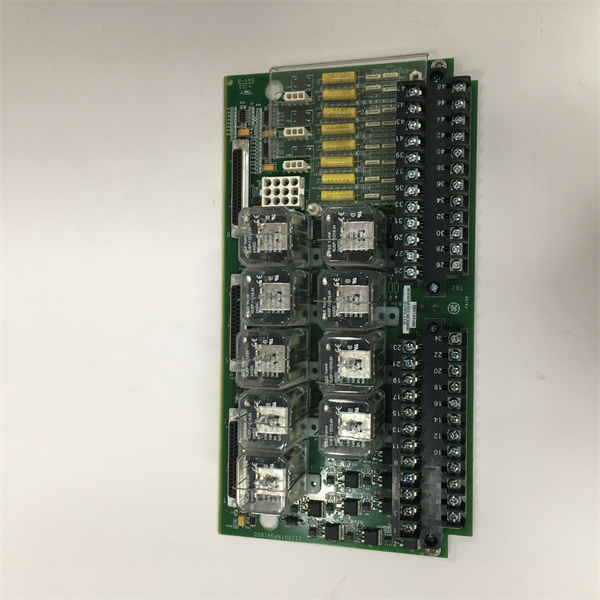

Product Overview

The GE IS200WREAS1ADB is a pivotal component within GE’s industrial automation and control ecosystem, specifically designed for applications related to turbine protection and emergency trip functions. As part of the esteemed Mark VIe series, this module plays a crucial role in safeguarding the operation of aero – derivative turbines. It serves as an emergency trip option board, working in tandem with other elements of the Mark VIe control system to ensure the safe and reliable operation of turbines. By integrating seamlessly with the PPRA turbine I/O packs, the IS200WREAS1ADB enables effective management of critical control signals. In scenarios where abnormal conditions are detected in the turbine operation, it can quickly initiate emergency trip actions, protecting the turbine from potential damage and ensuring the overall safety of the industrial process.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200WREAS1ADB |

| Manufacturer | General Electric |

| Product Type | Turbine Emergency Trip Option Board |

| Series | Mark VIe |

| Technology | Surface Mount |

| Size | 33.0 cm high x 17.8 cm wide |

| Temperature Range | -30°C to 65°C |

| MPU Pulse Rate Range | 2 Hz to 20 kHz |

| MPU Pulse Rate Accuracy | 0.05 percent |

| Connector Type | DB connector (for specific connection details, refer to installation guide) |

| Relay Configuration | Six solid – state relays (used for control and switching functions) |

| Power Connector | Pattern lock power connector (ensures secure power connection) |

| Jumpers | Present (used for configuration purposes) |

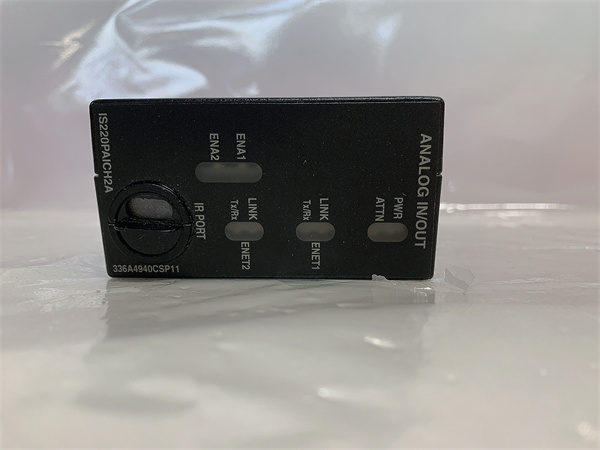

IS200AEPAH1ACB

Main Features and Advantages

Reliable Emergency Trip Function: The GE IS200WREAS1ADB is engineered to provide a highly reliable emergency trip function for aero – derivative turbines. In the event of any abnormal parameters such as over – speed, high vibration, or critical temperature deviations in the turbine, it can rapidly respond and trigger the emergency shutdown mechanism. This helps prevent catastrophic failures and costly repairs, safeguarding the integrity of the entire turbine system.

Precise Signal Management: It plays a key role in managing contact inputs within the system. Through its JH1 connector, it supplies essential wetting power, with pin 1 for positive wetting voltage, pin 2 as ground, and pin 3 for negative or return wetting voltage. This precise power distribution ensures consistent signal integrity across all contact inputs, enabling accurate monitoring and control of turbine – related signals.

Easy Installation: The board is designed for straightforward installation. When connecting it to the terminal board, the connectors are equipped with keying mechanisms. This ensures that they can only be mated correctly when properly aligned. Once aligned, firmly pressing on the four screw heads surrounding the connector area secures the connection, making the installation process both simple and reliable for technicians.

Precise Signal Management: It plays a key role in managing contact inputs within the system. Through its JH1 connector, it supplies essential wetting power, with pin 1 for positive wetting voltage, pin 2 as ground, and pin 3 for negative or return wetting voltage. This precise power distribution ensures consistent signal integrity across all contact inputs, enabling accurate monitoring and control of turbine – related signals.

Easy Installation: The board is designed for straightforward installation. When connecting it to the terminal board, the connectors are equipped with keying mechanisms. This ensures that they can only be mated correctly when properly aligned. Once aligned, firmly pressing on the four screw heads surrounding the connector area secures the connection, making the installation process both simple and reliable for technicians.

Application Field

Power Generation: In power plants that utilize aero – derivative turbines for electricity generation, the GE IS200WREAS1ADB is an essential component. It continuously monitors the turbine’s operating conditions and is ready to initiate an emergency trip if any dangerous situations arise. For example, if the turbine’s speed exceeds the safe limit due to a malfunction in the governor system, the module will quickly shut down the turbine to prevent over – speeding and potential damage to the generator and other connected equipment.

Oil and Gas Industry: In oil and gas production facilities, turbines are used for various purposes such as gas compression and powering pumps. The IS200WREAS1ADB is deployed to protect these turbines. In a gas compressor station, if there is a sudden loss of lubrication or a spike in the temperature of the compressor, the module can immediately trigger an emergency trip, ensuring the safety of the equipment and preventing disruptions to the gas transportation process.

Industrial Manufacturing with Turbine – Driven Machinery: In industries like manufacturing plants that use turbine – driven machinery for processes such as high – speed production lines or large – scale material handling, the GE IS200WREAS1ADB provides crucial protection. For instance, in a paper mill where a turbine drives the main production machinery, the module can safeguard the equipment from unexpected failures, maintaining the continuity of the manufacturing process and reducing production losses.

Oil and Gas Industry: In oil and gas production facilities, turbines are used for various purposes such as gas compression and powering pumps. The IS200WREAS1ADB is deployed to protect these turbines. In a gas compressor station, if there is a sudden loss of lubrication or a spike in the temperature of the compressor, the module can immediately trigger an emergency trip, ensuring the safety of the equipment and preventing disruptions to the gas transportation process.

Industrial Manufacturing with Turbine – Driven Machinery: In industries like manufacturing plants that use turbine – driven machinery for processes such as high – speed production lines or large – scale material handling, the GE IS200WREAS1ADB provides crucial protection. For instance, in a paper mill where a turbine drives the main production machinery, the module can safeguard the equipment from unexpected failures, maintaining the continuity of the manufacturing process and reducing production losses.

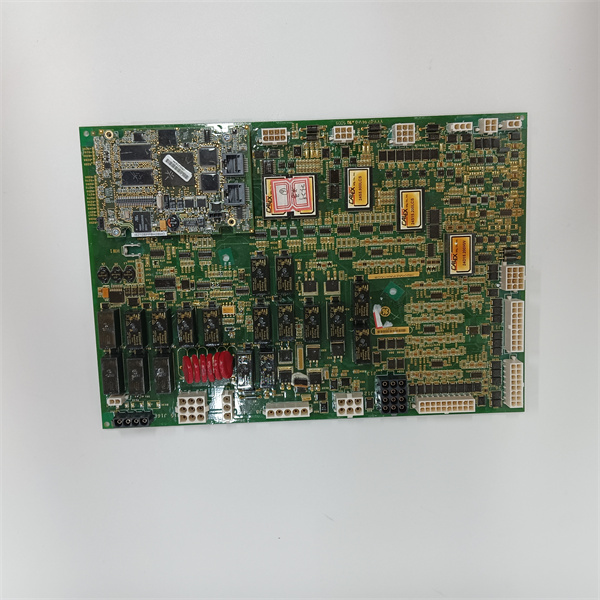

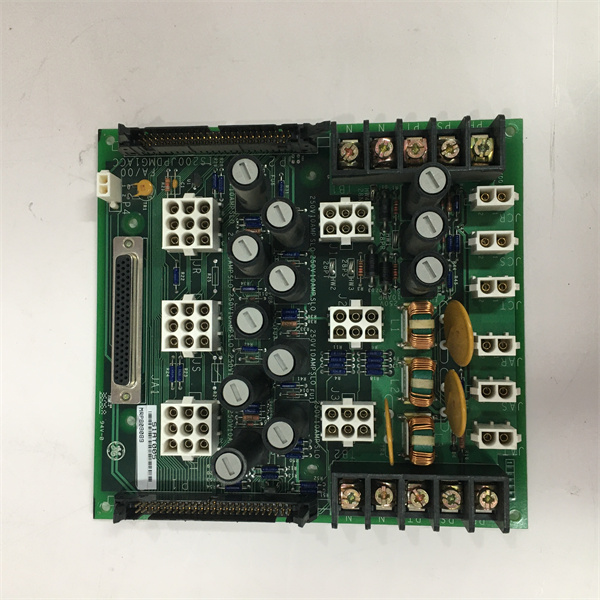

IS200JPDMG1ACC S1AT005

Related Products

- GE IS200WREAS1A: Similar in function to the IS200WREAS1ADB, but may have different revisions or minor differences in features. It also serves as an aero – derivative turbine emergency trip board within the Mark VIe series, but the IS200WREAS1ADB might have additional capabilities or design optimizations.

- GE IS220PPRASIA: This is an I/O pack that the IS200WREAS1ADB integrates with. The IS220PPRASIA is responsible for handling input and output signals in the overall turbine control system, and the IS200WREAS1ADB works in tandem with it to manage emergency – related signals and control functions.

- GE IS200HFPAG1ADB: A high – frequency ac/fan power supply board from the Mark VI series. While it has a different primary function of power supply for fans and related components, in a complete turbine control setup, it may be part of the overall power management system that supports the operation of the IS200WREAS1ADB and other modules.

- GE IS200SDIIH1ADB: An electronic module that functions as a digital input and output module. It can be used in the same industrial control environment as the IS200WREAS1ADB. In some cases, the digital signals processed by the IS200SDIIH1ADB may be related to the conditions that the IS200WREAS1ADB monitors for emergency trip decisions.

- GE IS200DAMEG1ADB: A gate driver board with IGBT. It is involved in the control of power – related functions in the turbine control system. Although its function is more focused on power driving and control, it may interact with the IS200WREAS1ADB in a complex industrial setup where overall system protection and operation are integrated.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS200WREAS1ADB, ensure that all power sources related to the turbine control system are turned off to avoid electrical hazards. Thoroughly inspect the board for any visible signs of damage during transit, such as cracks on the circuit board or bent connectors. Verify that the installation location is clean and free from dust and debris. Check the compatibility of the board with the existing Mark VIe system components, especially the terminal board it will be connected to. Make sure to have all the necessary tools, such as screwdrivers with appropriate sizes for securing the connections, ready for installation.

Maintenance recommendations: Regularly check the connections of the IS200WREAS1ADB to ensure they are secure. Over time, vibrations in the industrial environment can cause connectors to loosen. Inspect the board for any signs of overheating, such as discoloration of components or a burnt smell. Monitor the performance of the emergency trip function through periodic testing procedures as per the system’s maintenance schedule. If any faults are detected, refer to the detailed product manual provided by GE for troubleshooting steps. Clean the board gently using a static – free brush to remove accumulated dust, as dust can affect the electrical performance of the components.

Maintenance recommendations: Regularly check the connections of the IS200WREAS1ADB to ensure they are secure. Over time, vibrations in the industrial environment can cause connectors to loosen. Inspect the board for any signs of overheating, such as discoloration of components or a burnt smell. Monitor the performance of the emergency trip function through periodic testing procedures as per the system’s maintenance schedule. If any faults are detected, refer to the detailed product manual provided by GE for troubleshooting steps. Clean the board gently using a static – free brush to remove accumulated dust, as dust can affect the electrical performance of the components.

Product Guarantee

GE stands firmly behind the quality of the GE IS200WREAS1ADB. The module undergoes rigorous quality control procedures during the manufacturing process to meet high – industry standards. In case of any manufacturing defects, GE offers a comprehensive warranty. Their global network of technical support teams is available to assist customers. Whether it’s providing guidance on installation, helping with troubleshooting complex issues, or offering advice on maintenance, GE’s experts are dedicated to ensuring the long – term reliable operation of the IS200WREAS1ADB. This reflects their commitment to delivering top – notch products and excellent customer service, giving users confidence in the performance and durability of the module in their critical industrial applications.