Description

Product Overview

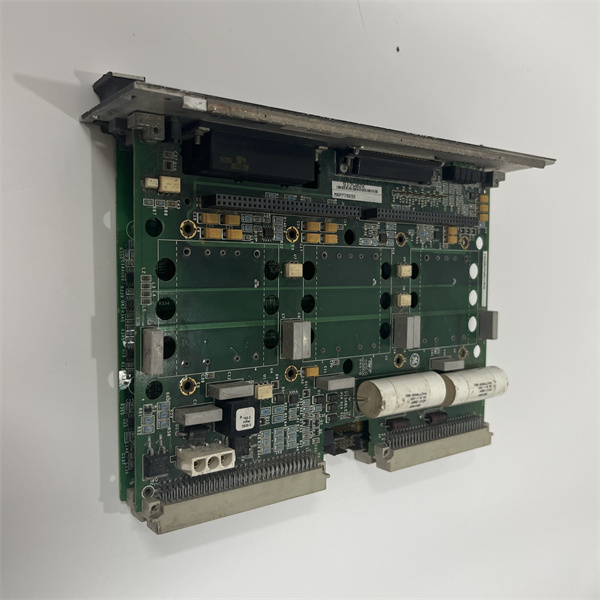

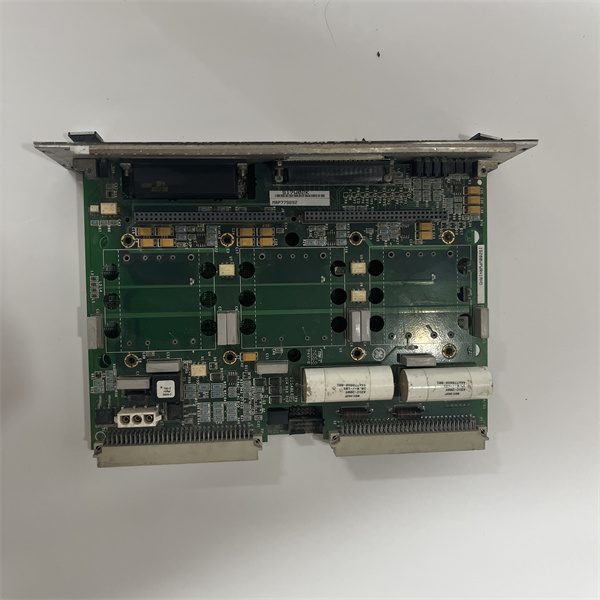

The GE IS200VPROH2B, GE IS200VPROH1BEF, and GE IS200VPWRH1AHD are integral components within the GE Mark VI gas turbine control system. These printed circuit boards (PCBs) play a crucial role in safeguarding the gas turbine and enabling accurate data management.

The GE IS200VPROH2B functions as an emergency turbine protection board. Along with the TPRO and TREG boards, it forms the independent overspeed protection system for the Mark VI system. It has nine thermocouple inputs dedicated to exhaust over – temperature protection, ensuring the turbine’s safe operation by closely monitoring temperature levels. This board also features three analog current inputs and backup synchronization check protection.

The GE IS200VPROH1BEF is also a protection board within the Mark VI system. It offers protection against electrical faults, such as overvoltage, under voltage, overcurrent, ground faults, short circuits, and reverse polarity. By constantly monitoring these electrical parameters, it helps prevent damage to the turbine and ensures the safety of personnel.

The GE IS200VPWRH1AHD is a high – precision analog measurement module. It is designed to provide reliable data acquisition for managing equipment like gas turbines. With input ranges for voltage (± 10 V) and current (4 – 20 mA), and a 16 – bit resolution for precise measurements, it accurately captures data. Its built – in filters for noise reduction enhance the quality of the acquired data, making it a vital part of the overall control and monitoring system.

Technical Specifications

GE IS200VPROH2B

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200VPROH2B |

| Manufacturer | GE |

| Product Type | Protection Board |

| Thermocouple Inputs | 9 for exhaust over – temperature protection |

| Analog Current Inputs | 3 |

| Backup Synchronization Check | Yes |

| Backplane Connectors | 2 |

| Power Supply | On – board, generates 5 V DC and 28 V DC from cabinet PDM |

| Operating Temperature | – 30°C to 70°C |

| Humidity Range | 5% – 95% non – condensing |

IS200VPROH2B IS200VPROH1BEF IS200VPWRH1AHD

GE IS200VPROH1BEF

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200VPROH1BEF |

| Manufacturer | GE |

| Product Type | Protection Board |

| Overvoltage Protection | Yes |

| Under Voltage Protection | Yes |

| Overcurrent Protection | Yes |

| Ground Fault Protection | Yes |

| Short Circuit Protection | Yes |

| Reverse Polarity Protection | Yes |

| Operating Temperature | – 30°C to 70°C |

| Humidity Range | 5% – 95% non – condensing |

GE IS200VPWRH1AHD

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200VPWRH1AHD |

| Manufacturer | GE |

| Product Type | Analog Measurement Module |

| Input Voltage Range | ± 10 V |

| Input Current Range | 4 – 20 mA |

| Resolution | 16 – bit |

| Sampling Rate | Up to 1 kHz |

| Signal Conditioning | Built – in filters |

| Physical Dimensions | 160 mm x 100 mm x 35 mm |

| Weight | 0.5 kg |

| Operating Temperature | – 20°C to 70°C |

| Humidity Range | 5% – 95% non – condensing |

Main Features and Advantages

GE IS200VPROH2B

- Robust Protection: With multiple protection mechanisms like thermocouple – based over – temperature protection and analog current monitoring, it effectively safeguards the turbine from various potential threats.

- Redundancy in Design: As part of the triple – redundant VPRO boards in the overspeed protection system, it adds an extra layer of reliability, ensuring continuous operation even in the event of a component failure.

- Versatile Connectivity: The multiple connectors on the board, including backplane, ribbon, and various front – panel connectors, enable seamless integration with other components in the Mark VI system.

GE IS200VPROH1BEF

- Comprehensive Fault Protection: Offering protection against a wide range of electrical faults, it acts as a shield for the turbine, preventing damage that could be caused by abnormal electrical conditions.

- Reliable Monitoring: Continuously monitors electrical parameters, allowing for quick detection and response to any faults, which helps in minimizing downtime and maintenance costs.

GE IS200VPWRH1AHD

- High – Precision Measurement: The 16 – bit resolution and wide input ranges ensure accurate data acquisition, which is crucial for precise control and monitoring of gas turbines.

- Noise – Resistant Design: Built – in filters reduce noise interference, resulting in cleaner and more reliable data, which is essential for making informed decisions in the control system.

IS200VPROH2B IS200VPROH1BEF IS200VPWRH1AHD

Application Field

Power Generation

In power plants equipped with gas turbines, the GE IS200VPROH2B, GE IS200VPROH1BEF, and GE IS200VPWRH1AHD are extensively used. The IS200VPROH2B and IS200VPROH1BEF protect the gas turbines from electrical faults and over – temperature conditions, ensuring stable power generation. The IS200VPWRH1AHD accurately measures analog signals from various sensors in the turbine system, providing real – time data for efficient operation and control. This helps in optimizing power output, reducing fuel consumption, and enhancing the overall reliability of the power generation process.

Industrial Manufacturing

In industrial manufacturing facilities where gas turbines are used for processes such as powering large – scale machinery or providing heat for industrial processes, these components are vital. The protection boards safeguard the gas turbines from electrical issues that could disrupt production. The analog measurement module provides accurate data for process control, enabling manufacturers to maintain consistent product quality and production efficiency.

Aerospace and Defense

In aerospace and defense applications, where gas turbines are used in aircraft engines and auxiliary power units, the GE IS200VPROH2B, GE IS200VPROH1BEF, and GE IS200VPWRH1AHD play critical roles. The protection boards ensure the safe operation of the gas turbines, protecting against electrical faults that could lead to catastrophic failures. The analog measurement module provides accurate data for engine performance monitoring, which is essential for flight safety and mission success.

Related Products

- GE IS200VPROH1B: Similar to IS200VPROH2B, it is also a protection board in the Mark VI system. However, it may have different input/output configurations or protection capabilities, offering options for different application requirements.

- GE IS210MACCH1AGG: A processor card in the GE product range. It can work in tandem with the protection and measurement boards mentioned. The processor card can process the data acquired by IS200VPWRH1AHD and act on the protection signals from IS200VPROH2B and IS200VPROH1BEF to control the overall system.

- GE IS200VSVOH1B: Another board within the Mark VI system. It may be related to valve control or some other aspect of the gas turbine operation, and can be integrated with the IS200VPROH2B, IS200VPROH1BEF, and IS200VPWRH1AHD to form a comprehensive control and protection system.

- GE IS200VRTDH1D: This board is likely involved in resistance – temperature – detector (RTD) measurements. It can complement the IS200VPWRH1AHD in providing temperature – related data, which is important for overall turbine monitoring and control.

- GE IS200VTCCH1CBB: It may be related to turbine control and can interact with the protection boards like IS200VPROH2B and IS200VPROH1BEF to ensure proper operation of the turbine, while also using the data from the measurement module IS200VPWRH1AHD for more accurate control.

Installation and Maintenance

Pre – installation preparation

- GE IS200VPROH2B: Before installing the GE IS200VPROH2B, ensure that the Mark VI system is powered off. Check the board for any physical damage during transit. Verify that the cabinet PDM power supply is functioning correctly and can provide the required 5 V DC and 28 V DC for the board’s on – board power supply. Make sure the connectors on the board match the corresponding slots and ports in the control cabinet.

- GE IS200VPROH1BEF: For the GE IS200VPROH1BEF, inspect the board for any signs of wear or damage. Ensure that the electrical environment where it will be installed meets the specified operating temperature and humidity requirements. Check the compatibility of the board with the existing electrical wiring and control system components.

- GE IS200VPWRH1AHD: When preparing to install the GE IS200VPWRH1AHD, verify the input signal ranges of the sensors that will be connected to it. Ensure that the sampling rate requirements of the overall system are compatible with the board’s capabilities. Check the physical dimensions of the installation location to ensure a proper fit.

Maintenance recommendations

- GE IS200VPROH2B: Regularly check the thermocouple inputs of the GE IS200VPROH2B for any signs of loose connections or corrosion. Monitor the analog current inputs for abnormal readings. Periodically test the backup synchronization check function. Clean the board gently to remove dust and debris that could affect its performance.

- GE IS200VPROH1BEF: Continuously monitor the electrical parameters that the GE IS200VPROH1BEF is protecting against. Check for any false alarms or missed fault detections. Update the board’s firmware if available to benefit from the latest protection algorithms. Inspect the board’s connectors for any signs of wear or poor contact.

- GE IS200VPWRH1AHD: Calibrate the GE IS200VPWRH1AHD periodically to ensure accurate measurement. Check the signal conditioning filters for any signs of malfunction. Monitor the data output for any noise or irregularities. Replace the board if the measurement accuracy deteriorates beyond the acceptable limits.

Product Guarantee

GE stands firmly behind the quality of the GE IS200VPROH2B, GE IS200VPROH1BEF, and GE IS200VPWRH1AHD. Each product undergoes rigorous quality control procedures during manufacturing to meet high – industry standards. GE offers a standard warranty for these products, covering any defects in materials and workmanship. Their global network of technical support teams is available to assist customers. Whether it’s answering installation – related questions, helping with complex troubleshooting, or providing advice on maintenance, GE’s experts are dedicated to ensuring the long – term reliable operation of these boards. This reflects GE’s confidence in the products and its commitment to customer satisfaction, allowing customers to rely on these components for their critical industrial applications.