Description

Product Overview

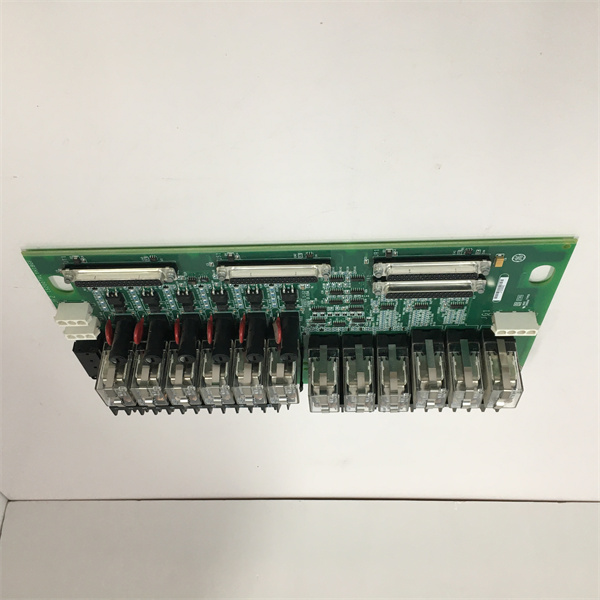

The GE IS200TTURH1CCC S1DF00Z is a crucial PCB component within the esteemed GE Mark VI Speedtronic series. Functioning as a turbine termination board, it plays an integral role in the overall operation of turbine control systems. This board is meticulously designed to interface with GE’s subsequent Speedtronic systems, including both the Mark VI and Mark Vie systems. Since its inception, the Speedtronic systems by GE have been at the forefront of industrial gas and steam turbine management, evolving from their initial release in the late 1960s to become highly sophisticated control solutions. The GE IS200TTURH1CCC S1DF00Z contributes to this sophistication by providing a reliable connection and control interface for various turbine – related operations. It works in tandem with other printed circuit boards (PCBs) such as the PTUR and VTUR boards, enabling the seamless control of generator synchronization, a critical aspect in power generation and distribution processes.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200TTURH1CCC S1DF00Z |

| Manufacturer | General Electric |

| Product Type | Turbine Termination Board |

| Series | Mark VI |

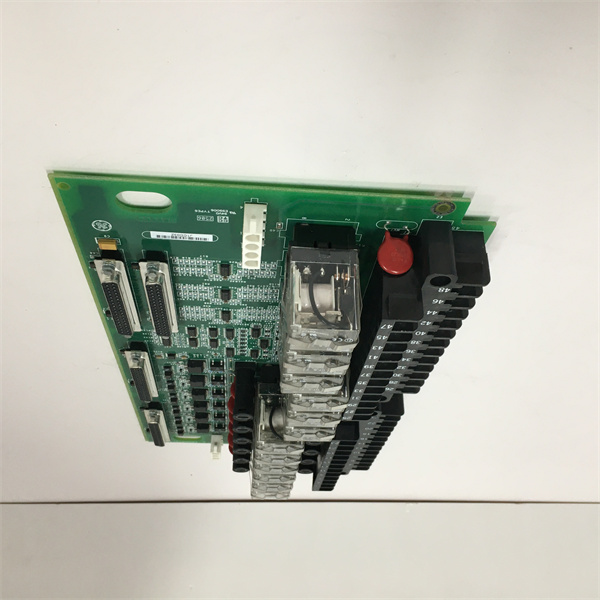

| Board Shape | Essentially rectangular with minor perforations |

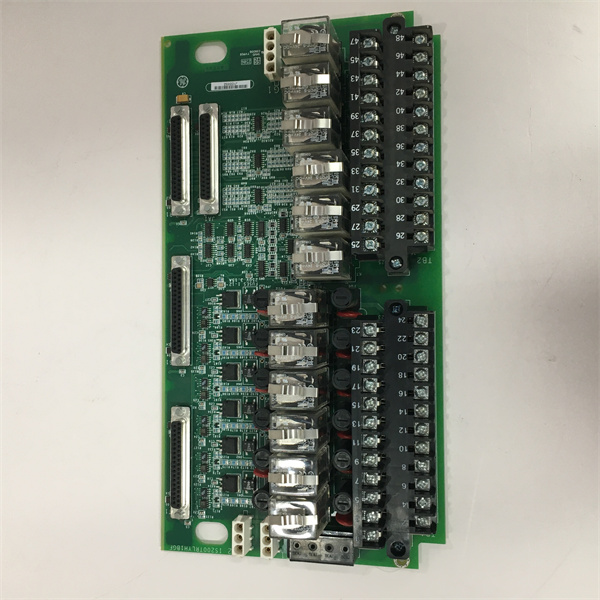

| Surface Components | Numerous surface – mounted relays, variable resistors |

| Central Features | Two transformers at the board’s center |

| Communication Connectors | D – shell connections (both male and female), plug connectors, terminal blocks |

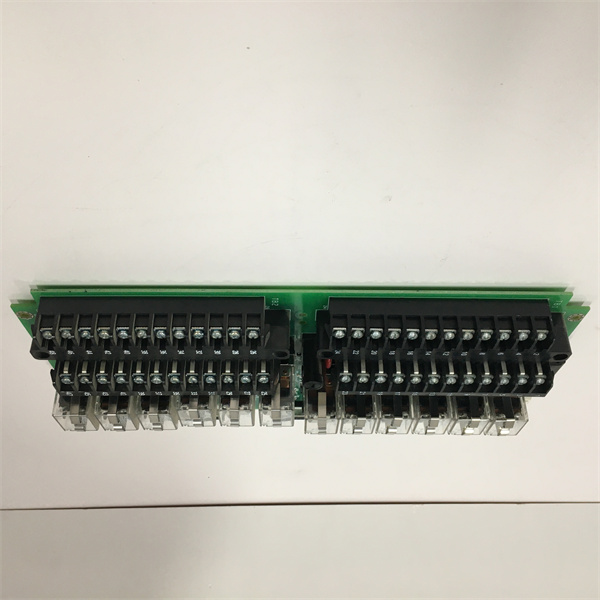

| Terminal Block Identification | Screw – mounted connectors numbered on two main terminal blocks |

| Configuration Switches | Two jumper switches for simplex or TMR voting |

IS200TTURH1CCC S1DF00Z

Main Features and Advantages

Precise Synchronization Control

The GE IS200TTURH1CCC S1DF00Z is designed to work in harmony with other boards like PTUR and VTUR, allowing for extremely accurate control of generator synchronization. In power plants, where the synchronization of generators is vital for stable power supply, this board ensures that the generators are in sync with the grid. This precision minimizes power fluctuations and potential damage to the electrical equipment, enhancing the overall efficiency of power generation and distribution.

Versatile Connectivity Options

Equipped with a variety of connectors including D – shell (both male and female), plug connectors, and terminal blocks, the board offers flexible connectivity. This versatility makes it easier to interface with different components within the turbine control system. Whether it’s connecting to sensors, actuators, or other control modules, the IS200TTURH1CCC S1DF00Z can accommodate various connection requirements, facilitating seamless integration within complex industrial setups.

Configurable Voting Modes

The presence of two jumper switches on the board is a significant advantage. These switches enable the alteration of board circuits to support either simplex or triple – modular redundant (TMR) voting. In simplex mode, the board operates with a single – path control, which can be suitable for less critical applications or in cases where cost – effectiveness is a priority. On the other hand, TMR voting provides a high level of redundancy and fault tolerance. In industrial environments where continuous operation is crucial, such as in large – scale manufacturing plants or power generation facilities, the ability to switch to TMR mode ensures that the system can continue to function even in the event of a component failure.

Application Field

In power generation plants, the GE IS200TTURH1CCC S1DF00Z is widely used in both gas and steam turbine control systems. It plays a key role in synchronizing the generators with the grid, ensuring a stable and reliable power supply. For example, in a combined – cycle power plant, the board helps in coordinating the operation of multiple turbines and generators, optimizing the overall power generation process.

Industrial manufacturing facilities that rely on large – scale motors and turbines also benefit from this board. In a steel mill, for instance, where massive induction motors are used for various processes like rolling and pumping, the IS200TTURH1CCC S1DF00Z can be part of the control system that monitors and manages the operation of these motors. By ensuring proper synchronization and control, it helps in maintaining the efficiency of the manufacturing processes and reducing downtime.

In the oil and gas industry, turbines are used for various applications such as gas compression and power generation for remote installations. The GE IS200TTURH1CCC S1DF00Z is utilized to control these turbines, providing the necessary interface for monitoring and controlling critical parameters. This ensures the smooth operation of oil and gas production, transportation, and processing facilities, even in harsh and remote environments.

IS200TTURH1CCC S1DF00Z

Related Products

- GE IS200PTUR: Works in conjunction with the GE IS200TTURH1CCC S1DF00Z in the turbine control system. It likely has specific functions related to power transfer or signal processing that complement the termination board’s role in overall turbine control.

- GE IS200VTUR: Another board that collaborates with the IS200TTURH1CCC S1DF00Z. It may be involved in voltage regulation or variable – speed control aspects of the turbine system, working together with the termination board to achieve comprehensive turbine operation control.

- GE Mark VI IS200EPCG1A: A different circuit board within the Mark VI series. While the IS200TTURH1CCC S1DF00Z focuses on turbine termination and synchronization – related tasks, the IS200EPCG1A may have functions more related to power conditioning or overall system control, but they are both part of the larger Mark VI ecosystem.

- GE IS200DSVOH1A: This printed circuit board is also from the Mark VI series. It might handle tasks such as signal detection and voltage handling in a different context compared to the IS200TTURH1CCC S1DF00Z, but they can be integrated within the same turbine control infrastructure.

- GE IS200ICBDH1A: A PCB in the Mark VI family. It could be involved in tasks like circuit protection or data handling, and although its function may differ from that of the GE IS200TTURH1CCC S1DF00Z, it can be used in combination to build a complete and efficient turbine control system.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS200TTURH1CCC S1DF00Z, ensure that the installation area is clean, free from dust and debris, and has appropriate electrostatic discharge protection. Check the board for any visible signs of damage during transit, such as bent pins or cracked components. Familiarize yourself with the overall turbine control system layout and the specific location where the board will be installed. Make sure that all the necessary tools, such as screwdrivers and anti – static wrist straps, are at hand. Also, verify that the power to the system is turned off to prevent any electrical accidents during installation.

Maintenance recommendations: Regularly inspect the IS200TTURH1CCC S1DF00Z for any signs of overheating, which could be indicated by discolored components or a burning smell. Check for loose connections at the various connectors on the board. Clean the board periodically using a non – conductive cleaning solution to remove any accumulated dust, as dust can affect the electrical performance over time. Monitor the operation of the board through the system’s diagnostic tools, if available. If any issues are detected, such as abnormal voltage readings or communication failures, refer to the manufacturer’s documentation for detailed troubleshooting steps. Keep the board’s software or firmware updated, if applicable, to benefit from the latest improvements and bug fixes.

Product Guarantee

GE stands firmly behind the quality of the GE IS200TTURH1CCC S1DF00Z. The product undergoes rigorous quality – control measures during manufacturing to meet high – industry standards. GE offers a comprehensive product guarantee. In case of any manufacturing defects, the company provides free repair or replacement within the warranty period, which is typically [X] years. Their global network of technical support teams is available to assist customers with any queries related to installation, operation, or maintenance. This reflects GE’s confidence in the reliability and performance of the IS200TTURH1CCC S1DF00Z, ensuring that industrial users can rely on this turbine termination board for their critical turbine control needs.