Description

Product Overview

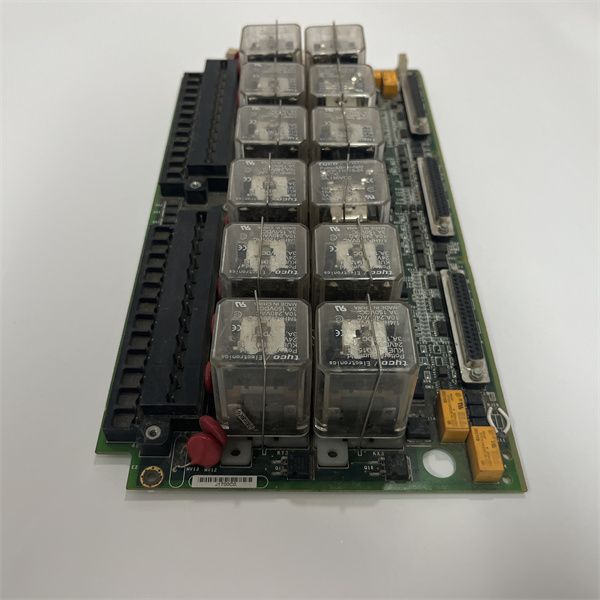

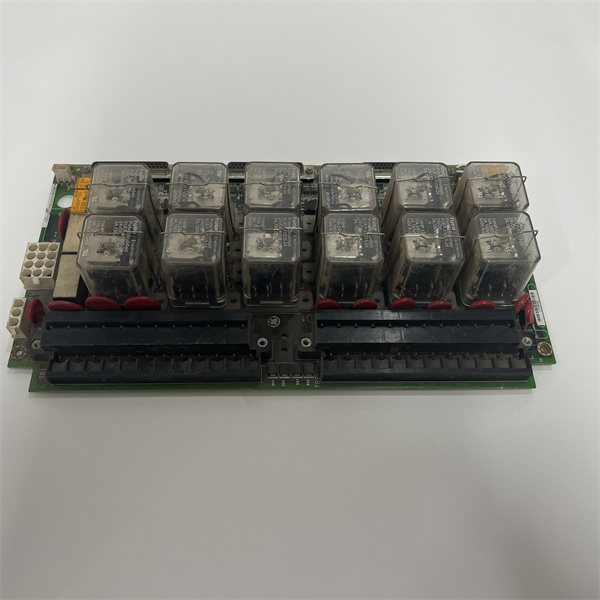

The GE IS200TREGH1BDB is a crucial turbine emergency trip terminal board developed by General Electric. As an integral part of GE’s Mark VI turbine control systems, it plays a vital role in ensuring the safe and reliable operation of turbines.

This terminal board is designed to handle the power supply for three emergency trip solenoids within the system. It works in close coordination with the I/O controller. The TREG (Trip Relay Electromagnetic Generator) on this board is fully controlled by the I/O controller, responsible for handling the positive pole of the DC power supply required to operate these solenoids. Meanwhile, it complements the TREG by providing the necessary negative pole of the DC power supply, ensuring a coordinated and balanced power distribution to the solenoids. This setup is essential for the proper functioning of the trip solenoids, which are crucial for the safety mechanisms of the turbine system, especially during emergency shutdown scenarios.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|

Product Model

|

IS200TREGH1BDB

|

|

Manufacturer

|

GE

|

|

Product Type

|

Turbine Emergency Trip Terminal Board

|

|

Series

|

Mark VI

|

|

Function

|

Power supply and control for emergency trip solenoids

|

|

Input/Output Processor

|

Yes

|

|

Operating Temperature

|

0°C – 60°C

|

|

Voltage Range

|

As per the requirements of the connected solenoids and control system (e.g., for 125V DC applications, it is commonly used)

|

|

Number of Relays

|

12, arranged in two rows of six

|

|

Terminal Blocks

|

Two long solid black terminal blocks on the left border, each containing 24 silver metallic terminals

|

|

Varistors

|

A series of around ten round red metal oxide varistors (MOVs) on the right of the terminal blocks

|

|

Connector Ports

|

A group of three jack connector ports on the right border, each with small pin ports

|

|

Capacitors

|

Four large rectangular – shaped solid yellow capacitors, two paired near the upper – right corner and two at the bottom – right corner

|

|

Conformal Coating

|

Yes, for protection in industrial environments

|

IS200TREGH1BDB

Main Features and Advantages

Critical Safety Function

The GE IS200TREGH1BDB is primarily designed for emergency situations. Its core responsibilities include emergency overspeed protection and emergency stop functions. By requiring a consensus from a group of relays before triggering the trip solenoids, the system significantly reduces the risk of false alarms or single – point failures. This design feature enhances the overall reliability and operational integrity of the turbine system, providing a robust safeguard against potential hazards.

Seamless System Integration

As part of the Mark VI series, it seamlessly integrates with other components in the GE turbine control system. The I/O processor on the board enables smooth data processing and communication between various control elements. This integration not only optimizes the system’s responsiveness and accuracy but also simplifies the overall system design and maintenance. It can easily interface with existing infrastructure and is compatible with future upgrades, making it a versatile choice for turbine control setups.

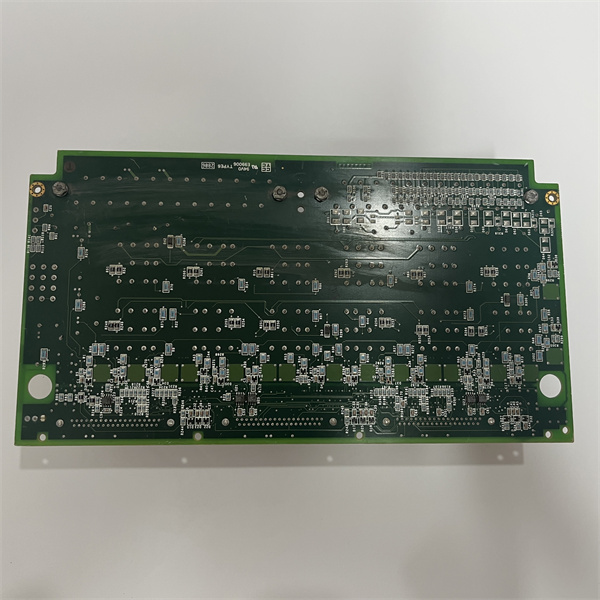

Durable and Reliable Construction

Built with durability in mind, the IS200TREGH1BDB is constructed using high – quality materials. The board is likely to have a ruggedized design to withstand the harsh environments typically found in industrial settings, such as power plants. The components on the board, including the relays, varistors, and capacitors, are carefully selected and arranged to ensure long – term reliable performance under extreme conditions. This durability reduces the frequency of component replacements and maintenance requirements, leading to lower overall operating costs.

Application Field

Power Generation

In power generation plants, whether they are gas – fired, coal – fired, or combined – cycle plants that rely on turbines, the GE IS200TREGH1BDB is an essential component. In gas – fired power plants, it plays a critical role in protecting the gas turbines. In the event of an emergency, such as an overspeed condition or a sudden malfunction, the board can quickly trigger the emergency trip solenoids. This action shuts down the turbine, preventing potential damage to the expensive turbine components and ensuring the safety of the entire power generation facility. Similarly, in coal – fired plants where steam turbines are used, the IS200TREGH1BDB provides the necessary emergency protection mechanism.

Industrial Manufacturing

Industries that use turbines for their manufacturing processes also benefit from the IS200TREGH1BDB. For example, in large – scale chemical plants, turbines are often used to drive compressors. The GE IS200TREGH1BDB can be used to safeguard these turbines. If there is a problem with the compressor, such as a sudden increase in pressure that could cause the turbine to malfunction, the board can initiate an emergency shutdown. In the paper industry, where turbines are used to drive large – scale paper – making machines, the IS200TREGH1BDB ensures the safety of the machinery by providing emergency trip capabilities.

IS200TREGH1BDB

Related Products

- GE IS200TREGH1ADB: Another version within the same product family. It may have some differences in terms of specific electrical characteristics or component arrangements. For example, it could be optimized for different voltage ranges or have a slightly different relay configuration, but it still serves a similar function of emergency trip control within the Mark VI turbine control system.

- GE IS200TRPGH1BDB: This is related to the power supply and control of the trip solenoids. While the IS200TREGH1BDB provides the positive pole of the DC power supply to the solenoids, the IS200TRPGH1BDB is responsible for providing the negative pole. They work in tandem to ensure the proper operation of the trip solenoids.

- GE Mark VI Central Controller: The central controller of the Mark VI system coordinates the overall operation. The IS200TREGH1BDB interfaces with this controller, receiving commands and sending back status information. The central controller uses the data from the IS200TREGH1BDB to make decisions regarding the operation and safety of the turbine system.

- GE Turbine Sensors: These sensors are used to monitor various parameters of the turbine, such as speed, temperature, and pressure. The data from these sensors is fed into the control system, including the IS200TREGH1BDB. Based on the sensor readings, the IS200TREGH1BDB can determine whether an emergency trip is required. For example, if a speed sensor detects an overspeed condition, the IS200TREGH1BDB may be triggered to initiate an emergency shutdown.

- GE Power Supply Modules for Mark VI: These power supply modules provide the necessary electrical power to the IS200TREGH1BDB and other components in the Mark VI system. A stable power supply is crucial for the proper functioning of the IS200TREGH1BDB, ensuring that it can operate the trip solenoids effectively during emergency situations.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS200TREGH1BDB, carefully read the installation manual provided by GE. Ensure that the installation environment meets the specified temperature and humidity requirements, as it should be within the 0°C – 60°C temperature range. Check the power supply to confirm that the voltage and current ratings are suitable for the board. If it is to be mounted in a control panel, make sure the panel is properly grounded. Inspect the connection ports on both the board and the mating components to ensure they are clean and free from any damage. Prepare the necessary wiring, using appropriate wire gauges based on the current – carrying requirements of the board and the connected solenoids.

Maintenance recommendations: Regularly inspect the GE IS200TREGH1BDB for any signs of physical damage, such as cracks in the board or loose connections. Check the relays for any signs of wear or malfunction. The relays should operate smoothly and make and break electrical connections cleanly. Monitor the temperature of the board during normal operation; if it exceeds the specified range, investigate the cause, which could be due to overloading or poor ventilation. Periodically clean the board to remove any accumulated dust, as dust can affect the performance of the components. If any issues are detected, refer to the troubleshooting guide in the user manual. In case of complex problems, contact GE’s technical support for assistance.

Product Guarantee

GE stands firmly behind the quality of the GE IS200TREGH1BDB. The product undergoes rigorous testing during the manufacturing process to meet high – quality standards. GE offers a standard warranty period, during which any defects in materials or workmanship will be rectified free of charge. Their experienced technical support team is available to assist customers with installation, configuration, and any technical issues that may arise during the product’s lifespan. Whether it’s a problem with the power supply functionality, communication with other components, or the operation of the trip solenoids, GE is committed to providing timely and effective solutions. This gives customers confidence in their investment and ensures the long – term, reliable operation of the IS200TREGH1BDB in various industrial applications.