Description

Product Overview

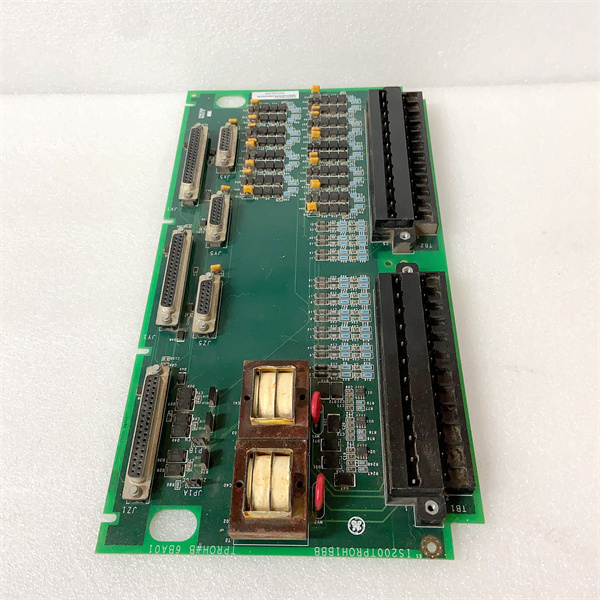

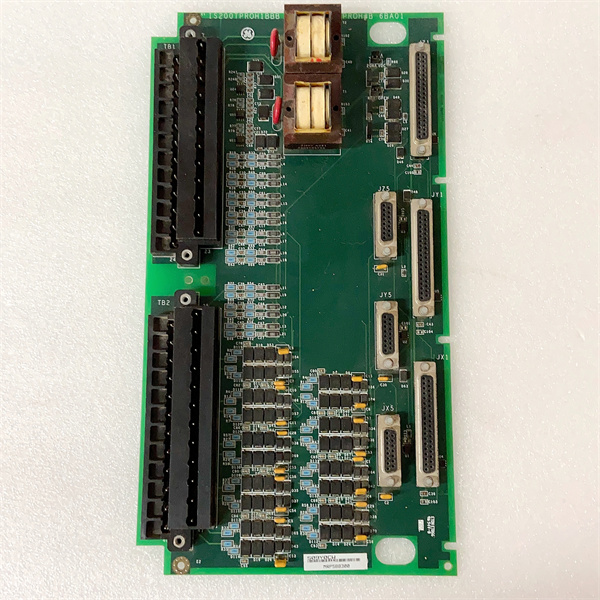

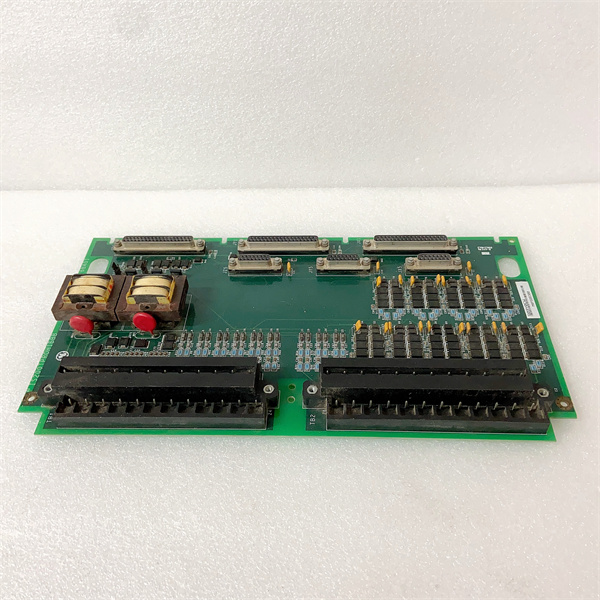

The GE IS200TPROH1BBB is a specialized protective termination board, meticulously crafted by General Electric for seamless integration within the renowned Mark VI series of industrial gas and steam turbines. In the intricate ecosystem of turbine control systems, this board plays a pivotal role. It serves as a reliable interface, ensuring that various electrical signals are accurately and securely terminated, which is crucial for the overall functionality and stability of the Mark VI system.

The Mark VI series, known for its advanced automation and management capabilities in industrial gas and steam turbine operations, heavily relies on components like the IS200TPROH1BBB to execute precise control. By providing a stable connection point for signals, the board helps in minimizing electrical interference and ensuring that the control system receives and transmits accurate data. This not only safeguards the integrity of the turbine control processes but also contributes to the overall efficiency and reliability of the entire industrial setup where these turbines are deployed.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200TPROH1BBB |

| Manufacturer | GE |

| Product Type | Protective Termination Board |

| Series | Mark VI IS200 |

| Shape | Long and rectangular printed circuit board (PCB) |

| Terminal Blocks | 2 large solid black ones on the left edge, each with 48 silver metallic terminals labeled 1 – 48 |

| Relays/Contactors | 2 red – square ones at the top, with yellow internal components |

| MOV (Metal Oxide Varistor) | Solid red ones, positioned to the left of each relay |

| Variable Resistors | 3 black potentiometers grouped vertically near the upper – right corner, marked with “r” |

| Capacitors | Several small yellow ones at the bottom, some paired |

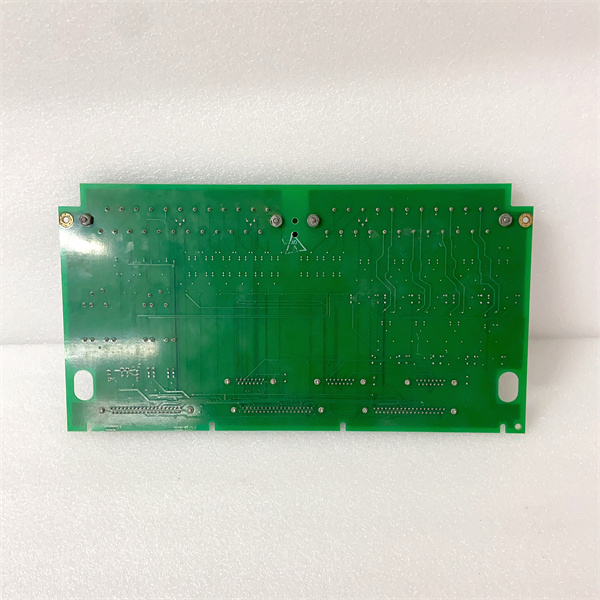

| Board Components | A wide variety of electronic components, ranging from small to large, mounted on both sides of the board |

| Component Identification | Components are marked with reference designations for easy identification |

IS200TPROH1BBB

Main Features and Advantages

Reliable Signal Termination

The GE IS200TPROH1BBB is designed with two large solid – black terminal blocks on its left edge. Each terminal block houses 48 silver – metallic terminals, clearly labeled from 1 to 48. This layout ensures that external wiring can be securely connected, providing a stable termination point for signals entering and exiting the board. The clear labeling simplifies installation and maintenance processes, allowing technicians to quickly identify and manage connections, thus minimizing the risk of incorrect wiring and associated system malfunctions.

Protection Against Electrical Transients

Equipped with solid – red metal oxide varistors (MOVs) placed adjacent to each relay, the board offers robust protection against voltage spikes and surges. In the high – voltage and high – stress environment of industrial turbines, electrical transients are common. The MOVs act as a shield, diverting excess voltage away from sensitive components like relays and other circuitry. This protection mechanism significantly enhances the board’s durability and reliability, ensuring that the turbine control system can withstand electrical fluctuations without performance degradation or component damage.

Adjustable Electrical Parameters

Near the upper – right corner of the IS200TPROH1BBB, three black variable resistors (potentiometers) are grouped vertically. These potentiometers are marked with the letter “r” and enable fine – tuning of electrical parameters within the circuit. This adjustability feature is invaluable in applications where precise control over the board’s performance is required. For example, it can be used to optimize the signal strength or adjust the sensitivity of certain components, ensuring that the turbine control system operates at its peak efficiency under various operating conditions.

IS200TPROH1BBB

Application Field

Power Generation

In power plants, whether they are gas – fired or steam – powered, the GE IS200TPROH1BBB is an essential component. In gas – turbine – based power generation, it helps in the accurate control of fuel injection and combustion processes. By securely terminating signals related to sensors that monitor gas flow, temperature, and pressure, it enables the control system to adjust these parameters in real – time. In steam – turbine power plants, the board plays a crucial role in regulating the steam flow to the turbine. Signals from sensors measuring steam pressure, temperature, and turbine speed are terminated on the IS200TPROH1BBB, allowing the control system to maintain optimal turbine speed and power output, ensuring stable and efficient power generation.

Industrial Manufacturing

Industries that rely on large – scale mechanical drive systems often use industrial turbines. For instance, in a paper mill, turbines are used to power large rollers and other machinery. The IS200TPROH1BBB ensures that the control signals for these turbines are accurately transmitted and terminated. It helps in maintaining the proper speed and torque of the turbines, which is essential for the smooth operation of the manufacturing process. In a steel plant, where turbines are used for various purposes such as powering blast furnaces and rolling mills, the board safeguards the integrity of the control system, preventing any disruptions that could lead to production delays or quality issues.

Oil and Gas

In the oil and gas industry, turbines are used in a variety of applications, from powering compressors in gas pipelines to driving pumps in oil refineries. The GE IS200TPROH1BBB is used to protect and manage the electrical connections in these turbine – driven systems. In gas pipelines, it ensures that the control signals for compressors, which regulate gas flow and pressure, are stable. In oil refineries, for turbines that power pumps handling crude oil or refined products, the board helps in maintaining the reliability of the control system. By protecting against electrical transients and providing reliable signal termination, it contributes to the safe and efficient operation of the entire oil and gas production and transportation infrastructure.

Related Products

- GE IS200 series modules: Modules like the GE IS200EPCTG1A are part of the same Mark VI series. While the IS200TPROH1BBB focuses on protective termination and signal management, the IS200EPCTG1A might be more involved in processing and controlling electrical signals at a different level within the overall Mark VI system. They work in tandem to provide comprehensive turbine control.

- GE IS200TPROH1BCB: This is another protective termination board in the GE product line. Similar to the IS200TPROH1BBB, it is designed for the Mark VI series. However, it may have some differences in component layout or specific termination capabilities, offering users options based on their particular application requirements.

- GE Mark VI control replacement components: Components such as the GE IS200DSVOH1A are replacement parts within the Mark VI series. They can be used to upgrade or repair existing systems, including those that use the IS200TPROH1BBB. These replacement components ensure that the Mark VI system can be maintained and optimized over time.

- GE turbine – specific sensors: Certain sensors designed by GE, which are compatible with the IS200TPROH1BBB, can accurately detect parameters like turbine speed, temperature, and pressure. These sensors feed data into the board, enabling it to perform its protective termination and signal – management functions effectively.

- GE communication modules: Communication modules in the GE product line can be used to connect the IS200TPROH1BBB to other parts of the industrial network. For example, they can transmit data from the board to a central control room, allowing operators to monitor and manage the turbine control system remotely.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS200TPROH1BBB, ensure that all power sources related to the turbine control system are turned off to prevent electrical hazards. Thoroughly inspect the board for any signs of physical damage that may have occurred during transit. Verify its compatibility with other components in the Mark VI system, including sensors, actuators, and other control modules. Follow the detailed installation instructions provided in the product manual carefully. Mount the board in the designated location within the control cabinet, ensuring that the two large terminal blocks are properly positioned. Securely fasten all connections, including wires connected to the terminals and any communication or power cables.

Maintenance recommendations: Regularly check the GE IS200TPROH1BBB for any signs of overheating, such as discoloration of components or abnormal heat generation. Monitor the performance of the board by checking the accuracy of the signals it terminates and the integrity of the connections. Periodically clean the board to remove dust and debris that could potentially affect its performance. If any issues are detected, such as intermittent signal loss or incorrect signal termination, refer to the product manual for troubleshooting steps. Replace any worn – out or damaged components, such as relays, variable resistors, or capacitors, promptly to maintain the board’s optimal functionality.

Product Guarantee

GE stands firmly behind the quality of the GE IS200TPROH1BBB. The board is manufactured to high – industry standards, with strict quality control measures implemented throughout the production process. During the warranty period, if there are any defects in materials or workmanship, GE offers comprehensive repair or replacement services. Their dedicated technical support team is available to assist customers with any installation – related queries, operational issues, or troubleshooting needs. This commitment to quality and customer service reflects GE’s confidence in the IS200TPROH1BBB and its ability to meet the demanding requirements of industrial turbine control applications, providing customers with peace of mind and long – term value.