Description

Product Overview

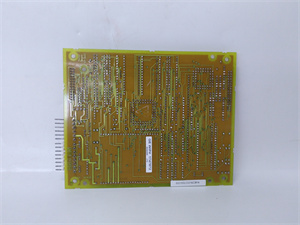

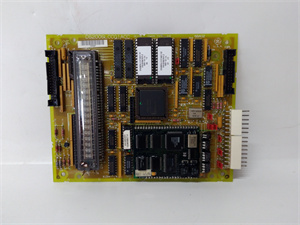

The GE IS200HSLAH2ADE is a high – performance printed circuit board meticulously crafted for GE’s esteemed Mark VI turbine control system series. As an HS SLR LNK interface board, it plays a pivotal role in the protection, control, and monitoring of heavy – duty gas and steam turbines. This series, part of GE’s Speedtronic family, is designed to be a modular, adaptable, and scalable system, and the IS200HSLAH2ADE is a key component that helps it meet the diverse needs of different turbine setups. It serves as a crucial link for seamless communication between various control modules within the turbine system, ensuring that real – time data is accurately transmitted, which is essential for maintaining optimal turbine performance. In the complex landscape of industrial automation, the GE IS200HSLAH2ADE is a fundamental element for ensuring the reliable operation of turbine – based systems.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200HSLAH2ADE |

| Manufacturer | GE |

| Product Type | Printed Circuit Board (HS SLR LNK Interface) |

| Series | Mark VI |

| Board Size | Approximately 8.26 x 11.43 x 1.91 cm (dimensions may vary slightly depending on specific installation requirements) |

| Weight | Approximately 0.09 kg (weight may vary based on installation needs) |

| Operating Temperature Range | – 40 °C to + 85 °C |

| Humidity Range | 5% to 95%, non – condensing |

| Communication Function | HS SLR LNK interface for data transfer between control modules |

| Component Configuration | Populated with components on top and bottom surfaces, including two transformers (Halo TG 110 – EO 50 N 5), six inductor coils, numerous transistors, resistors, capacitors, diodes, and over twenty integrated circuits (including a field programmable gate array at U1) |

| Mounting | Drilled for mounting, but does not use the Mark VI series’ typical VME rack mounting faceplate |

IS200HSLAH2ADE

Main Features and Advantages

Reliable Communication: The GE IS200HSLAH2ADE is engineered to provide highly reliable data communication. Its HS SLR LNK interface is designed to ensure seamless data transfer between different control modules within the Mark VI turbine control system. This reliability is crucial for maintaining the stable operation of heavy – duty gas and steam turbines, as any disruption in communication could lead to inefficiencies or even system failures.

Robust Construction: With components on both the top and bottom surfaces, and a build that includes high – quality transformers, inductor coils, and integrated circuits, this board is constructed to withstand the harsh conditions often found in industrial environments. The use of multiple components for insulation and voltage protection further enhances its durability, making it suitable for long – term use in demanding applications.

Flexible Integration: Despite not using the standard VME rack mounting faceplate, the IS200HSLAH2ADE can be easily integrated into the Mark VI system. Its modular design allows for straightforward installation and connection to other components, enabling it to be adapted to different turbine control setups, whether for new installations or upgrades to existing systems.

Robust Construction: With components on both the top and bottom surfaces, and a build that includes high – quality transformers, inductor coils, and integrated circuits, this board is constructed to withstand the harsh conditions often found in industrial environments. The use of multiple components for insulation and voltage protection further enhances its durability, making it suitable for long – term use in demanding applications.

Flexible Integration: Despite not using the standard VME rack mounting faceplate, the IS200HSLAH2ADE can be easily integrated into the Mark VI system. Its modular design allows for straightforward installation and connection to other components, enabling it to be adapted to different turbine control setups, whether for new installations or upgrades to existing systems.

Application Field

Power Generation: In power plants that rely on gas or steam turbines, the GE IS200HSLAH2ADE is an essential component. It enables seamless communication between the turbine control unit and other critical systems. For example, it can transfer data related to turbine speed, temperature, and pressure to the control system, allowing for precise adjustments to optimize power generation efficiency. In a large – scale thermal power plant, the board helps ensure that the steam turbine operates at peak performance, minimizing energy waste and maximizing electricity output.

Industrial Manufacturing: In manufacturing facilities where turbines are used to drive machinery, the IS200HSLAH2ADE plays a vital role. It can communicate with other automation components to synchronize the operation of various equipment. For instance, in a paper mill where a steam turbine drives the paper – making machinery, the board can ensure that the speed of the turbine is coordinated with the movement of the conveyor belts and the operation of the paper – forming machines, resulting in a smooth and efficient production process.

Oil and Gas Industry: In oil refineries and gas processing plants, turbines are often used for various purposes such as compression and power generation. The GE IS200HSLAH2ADE is used to monitor and control these turbines. It can transmit data about the performance of the turbines to the central control room, allowing operators to make informed decisions. For example, it can send information about the gas composition in a gas turbine used for power generation in an oil refinery, enabling adjustments to be made to ensure clean and efficient combustion.

Industrial Manufacturing: In manufacturing facilities where turbines are used to drive machinery, the IS200HSLAH2ADE plays a vital role. It can communicate with other automation components to synchronize the operation of various equipment. For instance, in a paper mill where a steam turbine drives the paper – making machinery, the board can ensure that the speed of the turbine is coordinated with the movement of the conveyor belts and the operation of the paper – forming machines, resulting in a smooth and efficient production process.

Oil and Gas Industry: In oil refineries and gas processing plants, turbines are often used for various purposes such as compression and power generation. The GE IS200HSLAH2ADE is used to monitor and control these turbines. It can transmit data about the performance of the turbines to the central control room, allowing operators to make informed decisions. For example, it can send information about the gas composition in a gas turbine used for power generation in an oil refinery, enabling adjustments to be made to ensure clean and efficient combustion.

IS200HSLAH2ADE

Related Products

GE IS200HSLAH2A: This is a related printed circuit board in the same product family. It likely shares some similarities in functionality with the IS200HSLAH2ADE, such as being an HS SLR LNK interface – related component for the Mark VI series. However, it may have different revisions or specific features tailored to certain applications within the turbine control system.

GE Mark VI Communication Cards: These cards are also part of the Mark VI system and work in tandem with the IS200HSLAH2ADE. They handle different aspects of communication within the system, with the IS200HSLAH2ADE focusing on the HS SLR LNK interface, while other communication cards may deal with broader network – level communication or communication with external devices.

GE Turbine Control Modules: There are various control modules in the Mark VI system that interact with the IS200HSLAH2ADE. These modules are responsible for different control functions, such as speed control, temperature regulation, etc. The IS200HSLAH2ADE provides the communication link for these modules to exchange data and work together effectively in controlling the turbine.

GE Power Supply Modules for Mark VI: Power supply modules are crucial for providing the necessary electrical power to components like the IS200HSLAH2ADE. A stable power supply from these modules ensures the reliable operation of the IS200HSLAH2ADE, and any issues with the power supply can directly impact the performance of the interface board.

GE Sensors for Turbine Monitoring: These sensors collect data on various parameters of the turbine, such as temperature, pressure, and vibration. The IS200HSLAH2ADE can receive data from these sensors and transmit it to other parts of the control system for analysis and decision – making. Without the proper functioning of sensors and the communication provided by the IS200HSLAH2ADE, accurate turbine monitoring and control would not be possible.

GE Mark VI Communication Cards: These cards are also part of the Mark VI system and work in tandem with the IS200HSLAH2ADE. They handle different aspects of communication within the system, with the IS200HSLAH2ADE focusing on the HS SLR LNK interface, while other communication cards may deal with broader network – level communication or communication with external devices.

GE Turbine Control Modules: There are various control modules in the Mark VI system that interact with the IS200HSLAH2ADE. These modules are responsible for different control functions, such as speed control, temperature regulation, etc. The IS200HSLAH2ADE provides the communication link for these modules to exchange data and work together effectively in controlling the turbine.

GE Power Supply Modules for Mark VI: Power supply modules are crucial for providing the necessary electrical power to components like the IS200HSLAH2ADE. A stable power supply from these modules ensures the reliable operation of the IS200HSLAH2ADE, and any issues with the power supply can directly impact the performance of the interface board.

GE Sensors for Turbine Monitoring: These sensors collect data on various parameters of the turbine, such as temperature, pressure, and vibration. The IS200HSLAH2ADE can receive data from these sensors and transmit it to other parts of the control system for analysis and decision – making. Without the proper functioning of sensors and the communication provided by the IS200HSLAH2ADE, accurate turbine monitoring and control would not be possible.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS200HSLAH2ADE, carefully review the product manual for detailed installation instructions. Ensure that the power to the Mark VI turbine control system is turned off to avoid electrical hazards. Inspect the area where the board will be installed to make sure it is clean, free of debris, and has the appropriate mounting provisions. Since the board is static – sensitive, take proper electrostatic discharge (ESD) precautions. Wear anti – static gloves and use ESD – safe tools when handling the board. Avoid touching the circuit board and components directly to prevent damage from static electricity.

Maintenance recommendations: Regularly check the IS200HSLAH2ADE for any signs of physical damage, such as cracks, bent connectors, or loose components. Clean the board periodically to remove dust and debris, as these can affect its performance over time. Monitor the communication status of the board and check for any error messages. If there are issues with data transfer or communication, refer to the product manual for troubleshooting steps. Keep track of available replacement parts, as some components on the board may become obsolete over time. In case of persistent problems, contact GE’s technical support for assistance.

Product Guarantee

GE stands firmly behind the quality of the GE IS200HSLAH2ADE. The board undergoes rigorous testing during the manufacturing process to ensure it meets high – industry standards. In terms of quality assurance, GE guarantees that the product is free from defects in materials and workmanship. In case of any quality – related issues within the warranty period, GE provides comprehensive after – sales service and technical support. Their team of experts is available to assist customers with installation, configuration, and any operational problems. This commitment reflects GE’s confidence in the product, giving customers peace of mind when integrating the IS200HSLAH2ADE into their industrial control systems.