Description

Product Overview

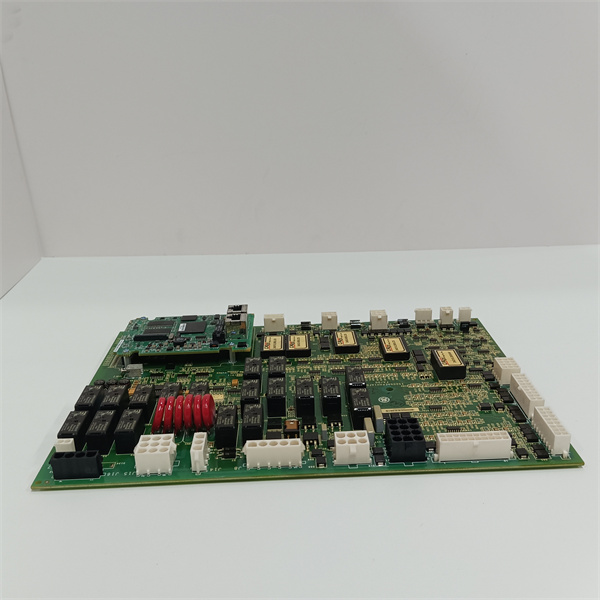

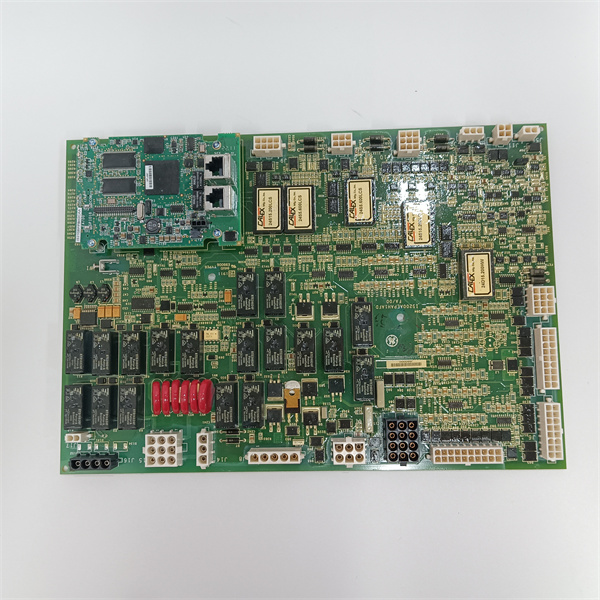

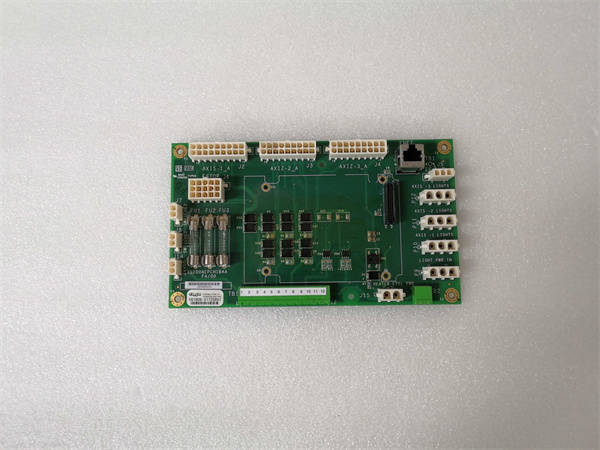

The GE IS200AEPCH1ABC is a pivotal printed circuit board (PCB) component within the esteemed Speedtronic Mark VI system. Engineered by General Electric, a global titan in industrial technology, this module is tailor – made for steam and gas industrial turbine systems. Its primary role is to execute power sensing and signal processing functions with utmost precision, thereby ensuring the safe and reliable operation of these critical industrial assets.

Integrating advanced Field – Programmable Gate Arrays (FPGAs) and a suite of integrated circuits, the IS200AEPCH1ABC is capable of processing real – time signals from an array of sensors and actuators. This empowers the system to respond rapidly and control operations with high accuracy. Whether it’s monitoring the rotational speed of a turbine, the temperature of the combustion chamber, or the pressure of the steam flow, this board plays a central role in collecting and processing the relevant data. In the complex ecosystem of the Speedtronic Mark VI system, the IS200AEPCH1ABC collaborates seamlessly with other components such as timing modules and safety devices, forming the backbone of a comprehensive control solution for industrial turbines.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS200AEPCH1ABC |

| Manufacturer | General Electric |

| Product Type | PCB Component |

| Series | Speedtronic Mark VI |

| Power Input | 24V DC, 8A |

| Interface | 1 RS – 422 interface |

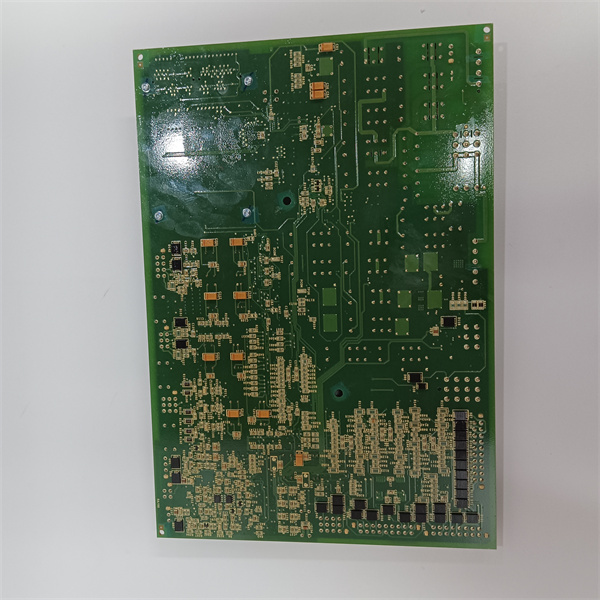

| Shape | Rectangular card without an attached faceplate |

| Mounting | Factory – made drill holes for easy mounting |

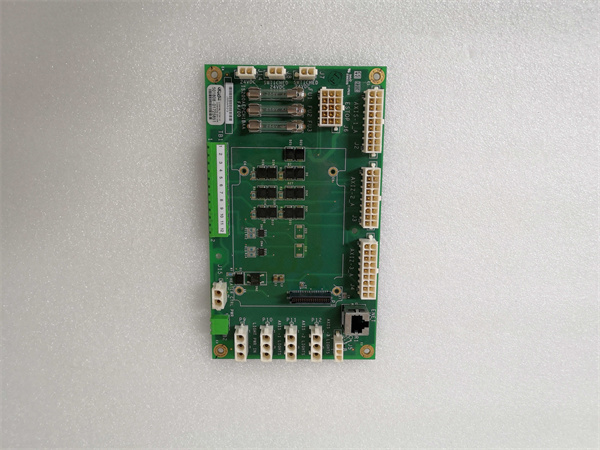

| Auxiliary Board | Typically has an auxiliary or daughterboard mounted near the center |

| Components | Includes FPGAs, integrated circuits, connectors, transistors, diodes, resistors, and capacitors |

| Markings | Various codes and reference designations on the surface |

| Input Points | 46 differential, DC – coupled |

| Input Update Rate | 10 ms |

| Resolution | 28 – or 48 – bit programmable |

| Accuracy | < 0.15 % of FSR, from 0 ° to 45 ° C |

| Common Mode Suppression | – 85 db (DC — 100 hz) |

| Input Over Range Protection | 160 VDC / 180 VAC continuous |

| Operating Temperature | – 40 °C to +70 °C |

| Storage Temperature | – 40 °C to +85 °C |

| Weight | Approximately 1.2 kg |

| Shipping Weight | 4.59 kg |

IS200AEPCH1BAA

Main Features and Advantages

High – Precision Signal Processing

The integration of FPGAs and advanced integrated circuits allows the IS200AEPCH1ABC to achieve high – precision signal processing. It can accurately convert, filter, and amplify signals from sensors, ensuring that the control system receives the most accurate data. This is crucial for maintaining the optimal performance of industrial turbines, as even minor inaccuracies in signal processing can lead to inefficiencies or malfunctions.

Versatile Interface

Equipped with an RS – 422 interface, the board enables seamless communication with other devices in the industrial control network. This interface is known for its reliability and relatively long – distance communication capabilities, making it suitable for connecting to sensors, actuators, and other control modules. It ensures stable data transfer, facilitating the smooth operation of the overall system.

Robust Design

Designed to withstand harsh industrial environments, the IS200AEPCH1ABC has a rugged construction. With factory – made drill holes for easy mounting, it can be securely installed in turbine control cabinets. The board’s ability to operate within a wide temperature range (- 40 °C to +70 °C) and its resistance to electrical over – range conditions ensure reliable performance in challenging industrial settings.

Auxiliary Board Integration

The presence of an auxiliary board near the center of the IS200AEPCH1ABC enhances its functionality. The auxiliary board, equipped with its own set of components such as an FPGA, integrated circuits, and various connectors, can perform additional processing tasks or interface with specific devices. This integration provides added flexibility and expandability, allowing the board to adapt to different application requirements.

IS200AEPCH1BAA

Application Field

Power Generation

In power plants, especially those relying on gas or steam turbines, the IS200AEPCH1ABC is indispensable. It monitors and controls key parameters like turbine speed, temperature, and pressure. By precisely processing signals related to these parameters, it enables the control system to optimize turbine operation. For example, it can adjust the fuel supply based on the temperature and pressure readings to ensure efficient combustion, maximizing power generation while minimizing fuel consumption and emissions.

Industrial Manufacturing

In manufacturing plants where industrial turbines are used for various processes such as powering compressors or driving large – scale machinery, the IS200AEPCH1ABC plays a vital role. It ensures the stable operation of these turbines, which is crucial for maintaining a consistent production flow. By accurately processing signals from sensors on the turbines, it can detect any anomalies early and trigger appropriate actions to prevent equipment failures and production disruptions.

Process Industries

Industries such as oil refineries, chemical plants, and petrochemical facilities also rely on the IS200AEPCH1ABC. In these environments, turbines are used for a variety of tasks, from driving pumps to powering separation processes. The board’s signal processing capabilities are used to monitor and control the turbines, ensuring the safe and efficient operation of these complex industrial processes. It can handle signals related to the flow of fluids, the pressure in reaction vessels, and the temperature of chemical reactions, all of which are critical for maintaining product quality and plant safety.

Related Products

IS200AEPCH1BAA

This is another PCB module in the same general product line. While sharing some similarities with the IS200AEPCH1ABC, it may have different input/output configurations or be optimized for slightly different applications within the industrial control domain. For example, it could be designed to handle a different set of signals or have a different power consumption profile.

DS200TCQAG1BHF

An analog I/O board that can work in tandem with the IS200AEPCH1ABC in a comprehensive industrial control system. The DS200TCQAG1BHF focuses on analog signal handling, and together with the IS200AEPCH1ABC‘s power sensing and digital signal processing capabilities, they can form a more complete solution for systems that require both analog and digital signal management.

IS200ACLEH1BCB

A PCB for the GE Mark VI Speedtronic series. It likely has its own unique functions, such as handling specific communication protocols or performing dedicated control tasks. It can be part of an integrated system where the IS200AEPCH1ABC is also present, each contributing to the overall operation and control of the industrial process.

IS200AEAAH1C

Another printed circuit board in the Mark VI series. It may be designed to interface with different types of sensors or actuators compared to the IS200AEPCH1ABC, or it could be used for a different stage of signal processing or control within the turbine control system.

IC200PWR001F

A power supply module. It is essential for providing the necessary electrical power to the IS200AEPCH1ABC and other components in the control system. A stable power supply is crucial for the proper functioning of the IS200AEPCH1ABC, and the IC200PWR001F is designed to meet these power requirements.

Installation and Maintenance

Pre – installation preparation: Before installing the IS200AEPCH1ABC, ensure that the power to the relevant system is switched off to prevent electrical hazards. Thoroughly inspect the board for any visible signs of damage during transportation. Check the installation location to ensure it has the appropriate mounting provisions, considering the factory – made drill holes on the board. Familiarize yourself with the wiring diagrams and connection requirements, especially regarding the RS – 422 interface. Make sure to have all the necessary tools, such as screwdrivers and anti – static equipment, on hand to prevent electrostatic discharge from damaging the sensitive components on the board.

Maintenance recommendations: Regularly clean the IS200AEPCH1ABC to remove dust and debris, as these can accumulate over time and affect the board’s performance. Periodically check the connection points of the RS – 422 interface and other connectors to ensure they are secure and free from corrosion. Monitor the board’s operating temperature, as it should remain within the specified range of – 40 °C to +70 °C. If any issues are detected, such as abnormal signal readings or communication failures, refer to the detailed product manual provided by GE for troubleshooting steps. Keep spare parts on hand, including replacement fuses and components, in case a quick replacement is needed to minimize downtime.

Maintenance recommendations: Regularly clean the IS200AEPCH1ABC to remove dust and debris, as these can accumulate over time and affect the board’s performance. Periodically check the connection points of the RS – 422 interface and other connectors to ensure they are secure and free from corrosion. Monitor the board’s operating temperature, as it should remain within the specified range of – 40 °C to +70 °C. If any issues are detected, such as abnormal signal readings or communication failures, refer to the detailed product manual provided by GE for troubleshooting steps. Keep spare parts on hand, including replacement fuses and components, in case a quick replacement is needed to minimize downtime.

Product Guarantee

GE stands firmly behind the quality of the IS200AEPCH1ABC. The company employs strict quality – control measures throughout the manufacturing process to ensure that each board meets high – industry standards. In the event of any manufacturing defects within the warranty period, GE offers comprehensive after – sales service. This includes free repair or replacement of the board, along with technical support from its team of experts. GE’s global network of support centers is available to assist customers promptly, providing solutions to any issues related to the IS200AEPCH1ABC. This commitment not only reflects GE’s confidence in the product’s reliability and performance but also its dedication to customer satisfaction, ensuring that industrial operations relying on this board can run smoothly and with peace of mind.