Description

Product Overview

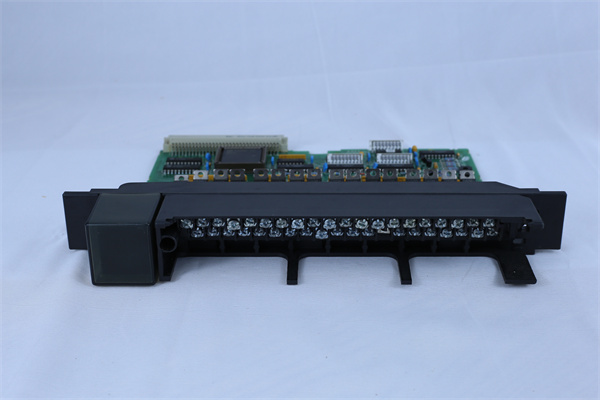

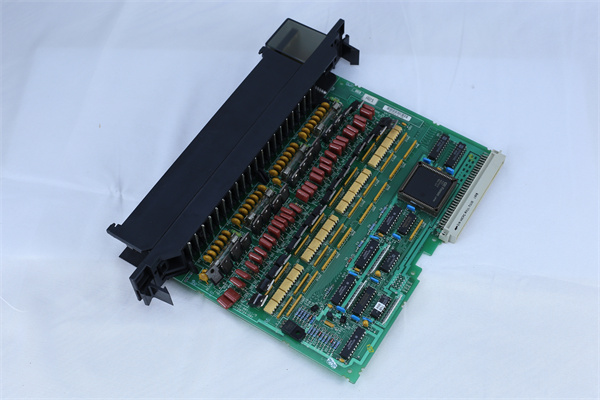

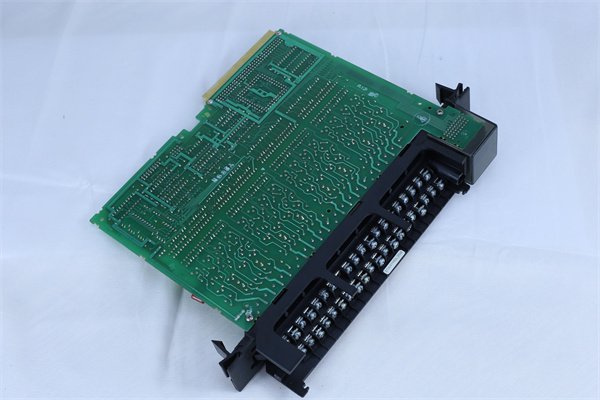

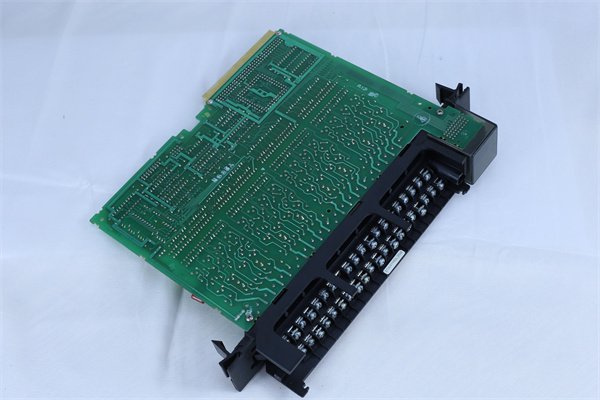

The GE IC697MDL350 is a high-performance digital input/output (I/O) module engineered by General Electric for industrial automation systems. Specifically designed for use with GE’s Series 90-70 Programmable Logic Controllers (PLCs), this module serves as a critical interface between the controller and field devices, enabling seamless communication and precise control in industrial environments.

The GE IC697MDL350 features a balanced configuration of 16 digital inputs and 16 digital outputs, providing a versatile solution for monitoring and controlling a wide range of industrial processes. Each input channel is designed to accept standard digital signals, while the output channels can drive various loads, including solenoids, relays, and indicator lights. This makes the module ideal for applications requiring real-time monitoring and control, such as manufacturing automation, process control, and material handling systems.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC697MDL350 |

| Manufacturer | General Electric |

| Product Type | Digital I/O Module |

| Series Compatibility | Series 90-70 PLCs |

| Number of Inputs | 16 |

| Number of Outputs | 16 |

| Input Voltage Range | 20.4-28.8 VDC |

| Output Voltage Range | 20.4-28.8 VDC |

| Output Current Capacity | 0.5 A per channel |

| Maximum Total Output Current | 8 A |

| Isolation | 2500 Vrms between I/O and logic |

| Response Time | ≤10 ms for inputs; ≤5 ms for outputs |

| Operating Temperature Range | -20°C to +60°C |

| Storage Temperature Range | -40°C to +85°C |

| Humidity | 5-95% non-condensing |

| Dimensions | 133.4 mm (H) x 101.6 mm (W) x 114.3 mm (D) |

| Weight | Approximately 0.68 kg |

| Mounting | DIN rail or panel mounting |

| Certifications | CE, UL, CSA, ATEX (Zone 2) |

IC697MDL350

Main Features and Advantages

Balanced I/O Configuration

The GE IC697MDL350 offers a perfect balance of 16 digital inputs and 16 digital outputs, making it suitable for applications requiring equal monitoring and control capabilities. This configuration eliminates the need for multiple modules, reducing system complexity and cost while maximizing efficiency.

High-Speed Response

With a response time of ≤10 ms for inputs and ≤5 ms for outputs, the module ensures rapid detection and processing of signals, enabling real-time control in dynamic industrial environments. This high-speed performance is critical for applications where timing is essential, such as motion control and automated assembly lines.

Robust Electrical Isolation

Featuring 2500 Vrms isolation between I/O and logic circuits, the GE IC697MDL350 provides excellent protection against electrical noise, surges, and ground loops. This isolation enhances system reliability and reduces the risk of damage to the PLC and connected devices, ensuring continuous operation in harsh industrial settings.

Wide Operating Temperature Range

The module’s ability to operate within a temperature range of -20°C to +60°C makes it suitable for deployment in diverse environments, from cold storage facilities to hot manufacturing plants. This wide temperature tolerance ensures consistent performance and reliability, even in extreme conditions.

Easy Installation and Maintenance

Designed for quick and easy installation, the GE IC697MDL350 can be mounted on a DIN rail or panel using standard hardware. The module’s compact design and plug-and-play connectivity simplify integration into existing systems, while its modular construction allows for easy replacement in the event of a failure, minimizing downtime and maintenance costs.

IC697MDL350

Application Field

Manufacturing Automation

In manufacturing plants, the GE IC697MDL350 is used to control and monitor various processes, such as conveyor systems, robotic arms, and assembly lines. The module’s digital inputs can detect the presence of objects or the status of switches, while its outputs can activate motors, solenoids, or other actuators, ensuring precise and efficient operation of manufacturing equipment.

Process Control

In industrial process control applications, such as chemical processing, water treatment, and power generation, the GE IC697MDL350 plays a crucial role in monitoring and controlling critical parameters. The module can interface with sensors to measure temperature, pressure, and flow, and use the digital outputs to regulate valves, pumps, and other equipment, maintaining optimal process conditions and ensuring product quality.

Material Handling

In material handling systems, such as warehouses and distribution centers, the GE IC697MDL350 is used to control automated guided vehicles (AGVs), conveyor belts, and sorting equipment. The module’s inputs can detect the position of goods or the status of sensors, while its outputs can control the movement and operation of material handling equipment, improving efficiency and reducing manual labor.

Packaging Machinery

In the packaging industry, the GE IC697MDL350 is used to control and monitor packaging machinery, such as filling machines, sealing machines, and labeling equipment. The module’s inputs can detect the presence of packages or the status of sensors, while its outputs can control the operation of the machinery, ensuring accurate and efficient packaging processes.

Related Products

GE IC697MDL340: A similar digital I/O module with 32 digital inputs and no outputs, designed for applications requiring a higher density of inputs.

GE IC697MDL360: A digital I/O module with 16 digital inputs and 16 digital outputs, offering sinking outputs for applications requiring this configuration.

GE IC697PWR710: A power supply module compatible with the Series 90-70 PLCs, providing reliable power to the GE IC697MDL350 and other modules in the system.

GE IC697CPU770: A high-performance CPU module for the Series 90-70 PLCs, capable of managing complex control tasks and communicating with the GE IC697MDL350 and other I/O modules.

GE IC697CHS790: A chassis module that provides a physical platform for mounting the GE IC697MDL350 and other modules in the Series 90-70 system, ensuring proper electrical connections and communication between modules.

GE IC697MDL360: A digital I/O module with 16 digital inputs and 16 digital outputs, offering sinking outputs for applications requiring this configuration.

GE IC697PWR710: A power supply module compatible with the Series 90-70 PLCs, providing reliable power to the GE IC697MDL350 and other modules in the system.

GE IC697CPU770: A high-performance CPU module for the Series 90-70 PLCs, capable of managing complex control tasks and communicating with the GE IC697MDL350 and other I/O modules.

GE IC697CHS790: A chassis module that provides a physical platform for mounting the GE IC697MDL350 and other modules in the Series 90-70 system, ensuring proper electrical connections and communication between modules.

Installation and Maintenance

Pre-installation preparation: Before installing the GE IC697MDL350, ensure that the power to the PLC system is turned off to prevent electrical shock or damage to the module. Verify that the chassis or rack where the module will be installed is clean and free of debris. Check the module for any signs of damage during shipping, such as cracked housings or loose connectors. Refer to the installation manual for specific instructions on mounting the module and connecting the input and output wires.

Maintenance recommendations: Regularly inspect the GE IC697MDL350 for signs of wear or damage, such as loose connections, corroded terminals, or overheating. Clean the module periodically to remove dust and debris, which can accumulate and affect its performance. Use a soft, dry cloth or compressed air to clean the module. Check the input and output signals regularly using a multimeter or other testing equipment to ensure they are within the specified ranges. If any issues are detected, replace the module or repair the damaged components as needed. Follow the manufacturer’s recommended maintenance schedule and procedures to ensure the long-term reliability and performance of the module.

Product Guarantee

General Electric provides a comprehensive product guarantee for the GE IC697MDL350, ensuring its quality and reliability. The module is backed by GE’s industry-leading warranty, which covers defects in materials and workmanship for a specified period from the date of purchase. In the event of a warranty claim, GE will repair or replace the defective module at no charge. Additionally, GE offers technical support and resources to assist customers with installation, operation, and maintenance of the GE IC697MDL350. This includes access to online documentation, training materials, and a team of experienced technical experts who can provide guidance and troubleshooting assistance. GE’s commitment to quality and customer satisfaction ensures that the GE IC697MDL350 meets the highest standards of performance and reliability in industrial automation applications.