Description

Product Overview

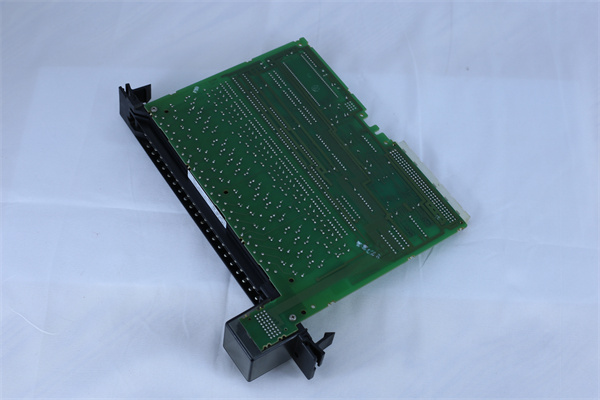

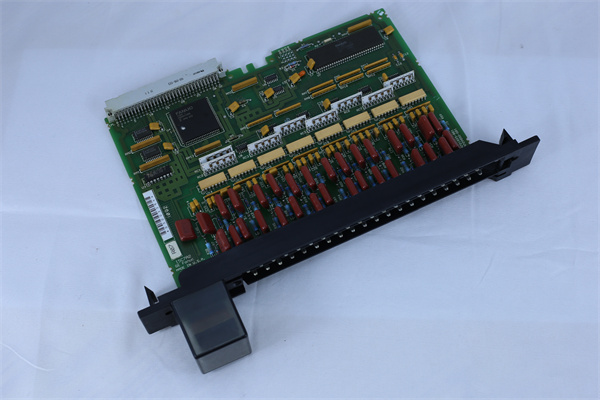

The GE IC697MDL250 is a discrete input module that holds significant importance within the GE Fanuc Series 90 – 70 Programmable Logic Controller (PLC) ecosystem. Engineered by General Electric, a globally recognized leader in industrial technology, this module is meticulously designed to serve as a reliable interface between the external industrial environment and the PLC system.

With 32 input points neatly divided into four isolated groups of eight points each, the IC697MDL250 offers remarkable flexibility. This isolation feature allows each group to be connected to a different phase of the AC supply, which is especially useful in complex industrial setups where diverse power sources or signal types need to be managed. It acts as a vital link for collecting and transmitting digital input signals from various sensors, switches, and other field devices to the PLC for further processing. This enables seamless integration and control within industrial automation systems, ensuring that operations run smoothly and efficiently. Whether it’s monitoring the status of machinery, detecting the presence of objects, or receiving commands from operator interfaces, the IC697MDL250 plays a fundamental role in translating real – world events into digital data that the PLC can understand and act upon.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC697MDL250 |

| Manufacturer | General Electric |

| Product Type | Discrete Input Module |

| Series | Fanuc Series 90 – 70 |

| Rated Voltage | 120 VAC |

| Number of Inputs | 32 (4 isolated groups of 8) |

| Input Current | 10 mA |

| Current Required | 0.35 amps |

| Frequency | 60 Hz |

| DC Power Requirement | Not required |

| Input Filter | 20 ms |

| Isolation | Each group of 8 points is isolated |

| Proximity Switch Compatibility | Yes |

| LED Indicators | Present for each input point’s status |

| Mechanical Keying | Present to prevent incorrect installation |

| User – Configurable I/O References | Yes |

| Compliance | Complies with IEC standard type 2 for reactive input |

| Configuration Method | Through programming software (MS – DOS or Windows) |

IC697MDL250

Main Features and Advantages

Multiple Isolated Input Groups

The division of 32 input points into four isolated groups is a major advantage. It allows for the use of different AC supply phases for each group. This is beneficial in scenarios where electrical interference might be an issue or when dealing with multiple independent electrical systems within an industrial setup. By separating the input signals in this way, the module can enhance the reliability and stability of the input data, reducing the risk of cross – talk and electrical noise interference.

Input Filter for Signal Integrity

Equipped with a 20 ms input filter, the IC697MDL250 is effective in reducing electrical noise that could otherwise corrupt the input signals. This filter helps to clean up the incoming digital signals, ensuring that the PLC receives accurate and stable data. In industrial environments filled with electromagnetic interference from motors, transformers, and other electrical equipment, this feature is crucial for maintaining the integrity of the input information, leading to more reliable control decisions.

Proximity Switch Compatibility

The module’s compatibility with proximity switches broadens its application scope. Proximity switches are widely used in industrial automation for tasks such as detecting the presence or absence of objects, measuring distances, and controlling the position of machinery. The IC697MDL250 can easily interface with these switches, enabling seamless integration into various industrial processes. This compatibility simplifies the design and implementation of industrial control systems, as engineers can readily incorporate proximity – switch – based sensors without having to worry about complex interface issues.

User – Configurable I/O References

Eliminating the need for jumpers or dip switches, the user – configurable I/O references of the IC697MDL250 offer great convenience. Users can customize the I/O settings according to their specific application requirements through programming software (either MS – DOS or Windows – based). This flexibility not only streamlines the configuration process but also allows for easy re – configuration in case of changes in the industrial process or system expansion. It reduces the chances of human error during the configuration process associated with physical switch – based settings.

Application Field

Industrial Automation

In manufacturing plants, the IC697MDL250 is extensively used to monitor the status of production machinery. For example, it can connect to limit switches on conveyor belts to detect the position of products or to sensors on robotic arms to ensure proper movement and operation. By providing accurate input data to the PLC, it enables the automation system to control the production process precisely, optimizing efficiency and product quality.

Power Generation

Within power plants, this module plays a role in monitoring various equipment. It can be connected to sensors that detect the status of circuit breakers, indicating whether they are open or closed. It can also monitor the position of valves in steam or gas pipelines. The input data from these sensors, processed through the IC697MDL250 and the PLC, helps in ensuring the safe and efficient operation of power – generation equipment.

Transportation Infrastructure

In traffic control systems, the module can be used to receive input signals from vehicle – detection sensors placed at intersections. These sensors, which are often proximity – based, can detect the presence of vehicles. The IC697MDL250 then transmits this information to a PLC – based traffic control system, which can adjust the timing of traffic lights to improve traffic flow and reduce congestion.

Packaging Industry

In packaging lines, the IC697MDL250 is used to monitor the status of packaging machines. It can connect to sensors that detect if a package is properly filled, sealed, or labeled. Based on the input signals received through the module, the PLC can control the operation of the packaging line, such as stopping the line if a packaging error is detected or triggering an alarm for operator intervention.

Related Products

IC697MDL240

This is another discrete input module in the GE Fanuc Series 90 – 70. While the IC697MDL250 has 32 input points, the IC697MDL240 may have a different number of input points, perhaps fewer. It could be more suitable for applications where a smaller number of discrete inputs are required, offering a more cost – effective solution for less complex systems.

IC697MDL350

This module might have different voltage requirements or input characteristics compared to the IC697MDL250. For instance, it could be designed to work with a different range of input voltages, making it applicable in industrial settings where the power supply characteristics are different from those suitable for the IC697MDL250.

IC697CPU781

A CPU module in the same series. The IC697MDL250 feeds input data to the CPU, and the IC697CPU781, with its processing capabilities, uses this data to execute control logic. They work in tandem within the PLC system, with the CPU being responsible for processing the input signals received via the IC697MDL250 and generating appropriate output commands.

IC693PWR322

A power supply module. It provides the necessary electrical power to the IC697MDL250 and other components in the PLC system. A stable power supply from the IC693PWR322 is crucial for the proper functioning of the IC697MDL250, ensuring that it can accurately detect and transmit input signals without disruptions due to power – related issues.

IC697MDL650RR

This module may have enhanced features or different isolation characteristics compared to the IC697MDL250. It could be designed for applications where higher levels of electrical isolation or more advanced input handling capabilities are required, such as in environments with high levels of electrical noise or in safety – critical systems.

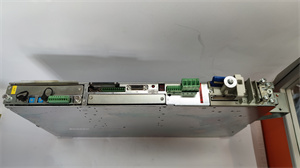

Installation and Maintenance

Pre – installation preparation: Before installing the IC697MDL250, ensure that the power to the PLC system is switched off to prevent electrical hazards. Inspect the module for any visible signs of damage during transportation. Check the installation location to ensure it has the appropriate mounting provisions, as the module is mechanically keyed for proper installation. Familiarize yourself with the wiring diagrams and connection requirements, especially regarding the connection of input signals to the appropriate input points. Make sure to have all the necessary tools, such as screwdrivers and wire strippers, on hand. Also, verify that the PLC programming software (MS – DOS or Windows – based) is installed and properly configured for setting the user – configurable I/O references.

Maintenance recommendations: Regularly clean the IC697MDL250 to remove dust and debris, as these can accumulate over time and affect the module’s performance. Check the status of the LED indicators for each input point periodically to monitor the input signals. If an input point’s LED shows an unexpected status, it could indicate a problem with the connected sensor or a wiring issue. Inspect the connection points of the input wires to ensure they are secure and free from corrosion. If any issues are detected, such as incorrect input readings or communication failures between the module and the PLC, refer to the detailed product manual provided by GE for troubleshooting steps. Keep spare parts on hand, such as replacement input modules, in case a quick replacement is needed to minimize downtime.

Maintenance recommendations: Regularly clean the IC697MDL250 to remove dust and debris, as these can accumulate over time and affect the module’s performance. Check the status of the LED indicators for each input point periodically to monitor the input signals. If an input point’s LED shows an unexpected status, it could indicate a problem with the connected sensor or a wiring issue. Inspect the connection points of the input wires to ensure they are secure and free from corrosion. If any issues are detected, such as incorrect input readings or communication failures between the module and the PLC, refer to the detailed product manual provided by GE for troubleshooting steps. Keep spare parts on hand, such as replacement input modules, in case a quick replacement is needed to minimize downtime.

Product Guarantee

GE stands firmly behind the quality of the IC697MDL250. The company employs strict quality – control measures throughout the manufacturing process to ensure that each module meets high – industry standards. In the event of any manufacturing defects within the warranty period, GE offers comprehensive after – sales service. This includes free repair or replacement of the module, along with technical support from its team of experts. GE’s global network of support centers is available to assist customers promptly, providing solutions to any issues related to the IC697MDL250. This commitment not only reflects GE’s confidence in the product’s reliability and performance but also its dedication to customer satisfaction, ensuring that industrial operations relying on this module can run smoothly and with peace of mind.