Description

Product Overview

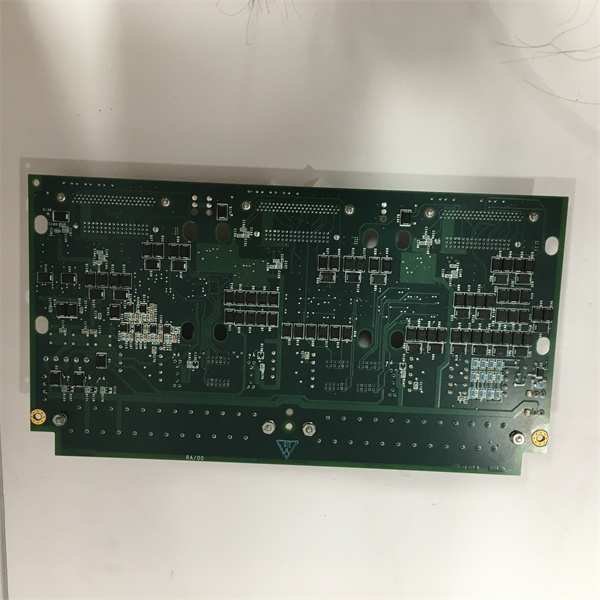

The GE IC697MDL241 is a discrete input module crafted by General Electric, a leading force in industrial automation. As part of the Series 90 – 70 family, it is engineered to meet the diverse and demanding requirements of industrial control systems.

This module serves as a crucial interface between field devices and Programmable Logic Controllers (PLCs). With 16 individually isolated input points, it can effectively handle signals from a wide range of sources such as pushbuttons, limit switches, selector switches, and both 2 – wire and 3 – wire electronic proximity switches. By providing reliable input data to the PLC, it enables accurate control and monitoring of industrial processes. Whether in a large – scale manufacturing plant with complex machinery or a smaller industrial setup, the GE IC697MDL241 plays a vital role in ensuring seamless operation and efficient control. Its design focuses on delivering stable performance in challenging industrial environments, making it an essential component for modern industrial automation.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC697MDL241 |

| Manufacturer | GE |

| Product Type | Discrete Input Module |

| Input Voltage | 240 VAC |

| Number of Input Points | 16 |

| Input Filter Time | 20 ms |

| Input Current (On State) | Typically 10 mA |

| Input Current (Off State, Leakage) | Can sink up to 5 mA |

| Isolation | Each point is individually isolated |

| Proximity Switch Compatibility | Yes |

| LED Indicators | Present to show on – off status of each point on logic side |

| Mechanical Keying | Yes, for correct replacement |

| Configuration Method | Via configuration function of ms – dos or windows programming software (running on Windows 95 or Windows NT over Ethernet TCP/IP or through the SNP port) |

| Operating Temperature | – 40 °C to + 85 °C |

| Communication Interface | Not specified as a primary feature, but can interface with PLC communication systems |

Main Features and Advantages

Isolated Input Points

The GE IC697MDL241 features 16 individually isolated input points. This isolation is crucial as it protects the module and the connected PLC from electrical interference and potential damage. For example, in an industrial setting with a lot of electrical noise from motors and other equipment, the isolated points ensure that the input signals remain clean and accurate, leading to reliable control decisions.

Proximity Switch Compatibility

It is compatible with a variety of proximity switches, both 2 – wire and 3 – wire types. This makes it highly versatile, as proximity switches are widely used in industrial applications for detecting the presence or absence of objects. Whether it’s in a packaging line to detect the position of products or in a conveyor system to monitor the movement of materials, the module can easily interface with these switches, providing seamless integration into different industrial setups.

Easy Configuration

The module can be configured through the configuration function of specific programming software. This software can run on Windows 95 or Windows NT, either over Ethernet TCP/IP or through the SNP port. The pre – installed configuration functionality in the software simplifies the setup process, allowing technicians to quickly configure the module according to the requirements of the industrial application without the need for complex manual adjustments using dip switches or jumpers.

IS200TSVCH1AED

Application Field

In manufacturing industries, the GE IC697MDL241 is extensively used in automated production lines. It can connect to pushbuttons that start or stop machinery, limit switches that define the boundaries of robotic arm movements, and proximity switches that detect the presence of parts on conveyor belts. For instance, in an automotive assembly plant, it helps control the precise movement of robotic arms for tasks like welding and part installation by accurately relaying input signals from these various devices to the PLC.

In the process control industry, such as in chemical plants or power generation facilities, the module plays a vital role. It can interface with sensors that monitor process parameters like temperature, pressure, and flow. For example, in a power plant, it can receive input from limit switches that indicate the position of valves controlling the flow of steam or from proximity switches that detect the presence of components in maintenance areas. This enables operators to have real – time information about the process, ensuring safe and efficient operation.

The GE IC697MDL241 is also applicable in material handling systems. In a warehouse with automated storage and retrieval systems, it can connect to sensors that detect the position of storage bins, the presence of goods on conveyors, and the operation status of forklifts. By providing accurate input data, it helps manage the flow of materials, optimizing the efficiency of the entire material handling process.

In the process control industry, such as in chemical plants or power generation facilities, the module plays a vital role. It can interface with sensors that monitor process parameters like temperature, pressure, and flow. For example, in a power plant, it can receive input from limit switches that indicate the position of valves controlling the flow of steam or from proximity switches that detect the presence of components in maintenance areas. This enables operators to have real – time information about the process, ensuring safe and efficient operation.

The GE IC697MDL241 is also applicable in material handling systems. In a warehouse with automated storage and retrieval systems, it can connect to sensors that detect the position of storage bins, the presence of goods on conveyors, and the operation status of forklifts. By providing accurate input data, it helps manage the flow of materials, optimizing the efficiency of the entire material handling process.

Related Products

- GE IC697MDL250: Another discrete input module in the same series. It may have different input voltage requirements or a different number of input points compared to the IC697MDL241. For example, it could be designed for applications that require a lower input voltage or a different density of input channels.

- GE IC697MDL350: This might be a module with additional features or different functionality. It could be a more advanced version in terms of communication capabilities or input signal processing, suitable for more complex industrial control scenarios where enhanced data handling is required.

- GE PLC Systems: These are the programmable logic controllers with which the IC697MDL241 is designed to work. Different PLC models offer varying levels of processing power, memory capacity, and communication interfaces. The module’s performance is optimized when paired with the right PLC system, ensuring seamless data transfer and control operations.

- GE Interface Cables: Specific cables are needed to connect the IC697MDL241 to other devices in the industrial network, such as PLCs or sensors. These cables are engineered to ensure reliable data transfer and electrical connection, minimizing signal interference and ensuring stable operation of the module within the overall system.

- GE Power Supply Modules: Modules that supply power to the IC697MDL241. They are designed to meet the exact power requirements of the input module, ensuring stable and efficient operation even in fluctuating electrical environments.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IC697MDL241, carefully review the installation manual provided by GE. Ensure that the installation environment meets the module’s requirements in terms of temperature, humidity, and electrical safety. Verify that the input voltage in the target system matches the 240 VAC requirement of the IC697MDL241. Check the compatibility of the module with the PLC or other control systems it will be connected to. Make sure all the necessary tools for installation, such as screwdrivers and wire strippers, are available. Also, confirm that the mechanical mounting location has the appropriate space and is free from vibrations that could affect the module’s performance.

Maintenance recommendations: Regularly inspect the GE IC697MDL241 for any signs of physical damage, such as cracks in the casing or loose connections. Monitor the input signals for any irregularities. If possible, use diagnostic tools to check the health of the module. Clean the module periodically to remove dust and debris that could affect its operation. In case of any issues, refer to the product manual for troubleshooting steps or contact GE’s technical support for assistance. Periodically, check the LED indicators on the module to ensure they are accurately reflecting the input status of each point.

Maintenance recommendations: Regularly inspect the GE IC697MDL241 for any signs of physical damage, such as cracks in the casing or loose connections. Monitor the input signals for any irregularities. If possible, use diagnostic tools to check the health of the module. Clean the module periodically to remove dust and debris that could affect its operation. In case of any issues, refer to the product manual for troubleshooting steps or contact GE’s technical support for assistance. Periodically, check the LED indicators on the module to ensure they are accurately reflecting the input status of each point.

Product Guarantee

GE stands firmly behind the quality of the GE IC697MDL241. The module undergoes rigorous quality – control procedures during manufacturing to meet high – industry standards. GE typically offers a comprehensive warranty, covering manufacturing defects for a specified period. In case of any quality – related issues within the warranty period, GE’s global technical support team is readily available. They can provide detailed guidance on installation, troubleshooting, and, if necessary, arrange for the repair or replacement of the GE IC697MDL241 promptly. This reflects GE’s commitment to delivering reliable and high – performing products for industrial automation, ensuring long – term customer satisfaction.