Description

Product Overview

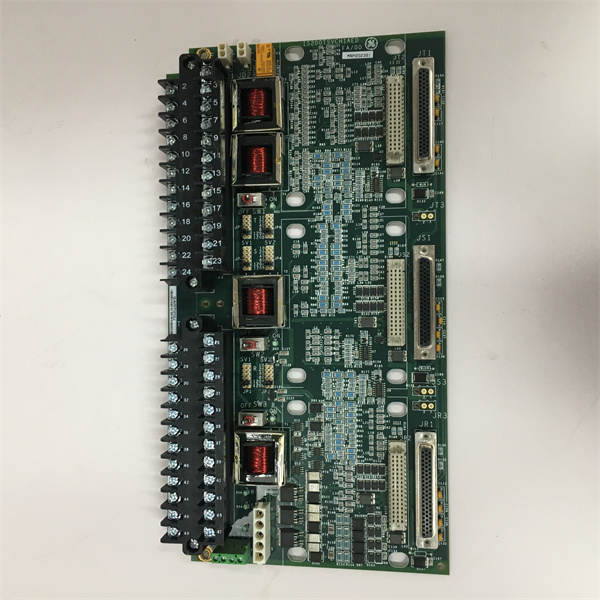

The GE IC697HSC700 is a high – performance high – speed counter (HSC) module, an integral part of GE’s Series 90 – 70 industrial automation solutions. Engineered to meet the complex demands of modern industrial control systems, this module plays a crucial role in applications that require precise and rapid counting operations.

The IC697HSC700 is designed to be installed in a single slot, offering space – efficient integration within the Series 90 – 70 system. It features five selectable counter types, providing versatility to adapt to different industrial scenarios. With 12 single – ended or differential inputs, it can interface with a wide variety of sensors and transducers, enabling accurate data acquisition. The input thresholds support TTL, non – TTL, and magnetic pickup, catering to diverse signal types commonly found in industrial settings. Additionally, it comes with four positive logic outputs equipped with LEDs that clearly indicate the output status, facilitating easy monitoring and troubleshooting. This module also includes an external oscillator and a built – in +5 VDC output, enhancing its functionality and compatibility with other components in the system. Configuration of the GE IC697HSC700 is a seamless process. It can be done via MS – DOS or Windows over Ethernet TCP/IP or the SNP port. The necessary configuration function is pre – installed on the compatible programming device, such as a suitable PC, allowing engineers to quickly and easily set up the module according to their specific application requirements.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC697HSC700 |

| Manufacturer | GE Fanuc |

| Product Type | High – Speed Counter Module |

| Counter Types | 5 selectable types |

| Inputs | 12 single – ended or differential |

| Input Thresholds | TTL, non – TTL, magnetic pickup |

| Outputs | 4 positive logic with LED status indicators |

| External Oscillator | Yes |

| Built – in +5 VDC Output | Yes |

| Configuration Method | Via MS – DOS or Windows over Ethernet TCP/IP or SNP port |

| Operating Voltage | [Specify, e.g., 24 VDC if applicable] |

| Operating Temperature Range | – 40 °C to + 85 °C |

| Current Consumption | [Specify value if available] |

| Mounting Type | Single – slot |

| Module Dimensions | [Provide length, width, height if available] |

| Weight | [Specify weight value if available] |

| Communication Interfaces | Ethernet TCP/IP, SNP port |

| Count Rates (Type – specific) | For types A – D: 200 kHz max with high – frequency filter, 30 Hz with low – frequency filter; for type E: 30 Hz with low – frequency filter, 200 kHz in up/down mode and 800 kHz in quad B mode with high – frequency filter |

| Input Filter Options | High – frequency filter (2.5 microseconds), low – frequency filter (12.5 milliseconds) |

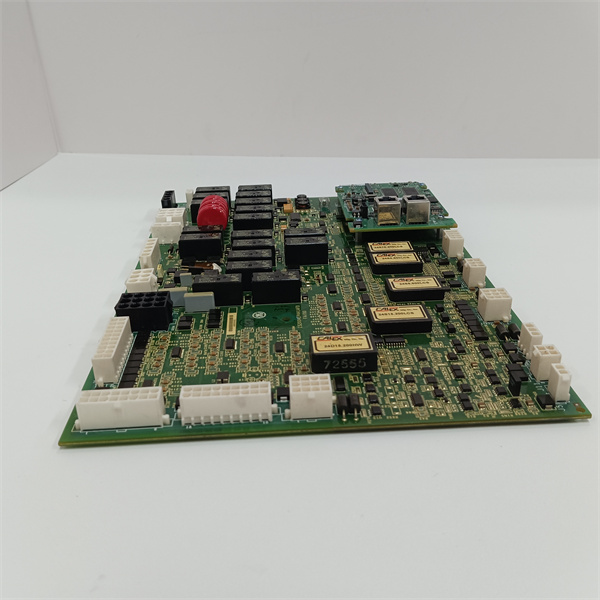

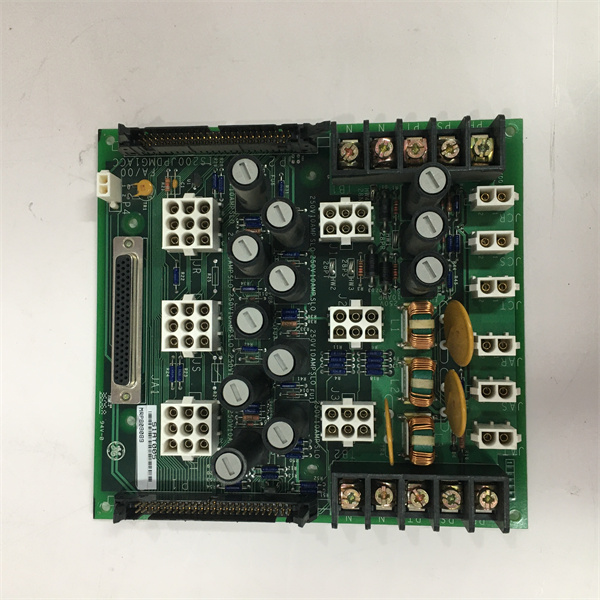

IS200JPDMG1ACC S1AT005

Main Features and Advantages

High – Speed Counting Capability

The GE IC697HSC700 can process rapid pulse signals directly, with count rates reaching up to 200 kHz or 800 kHz for type E in a quad B mode. This high – speed counting ability is crucial for applications where split – second precision is required, such as in high – speed manufacturing lines where components are being counted at a very fast pace. It can accurately sense inputs, process input count data, and control outputs without the need for constant communication to the PLC CPU, reducing latency and improving overall system response time.

Versatile Counter Configurations

With five selectable counter types (A, B, C, D, and E), the IC697HSC700 can be tailored to different industrial applications. Each counter type has 12 inputs and four outputs (preset), and some even offer PLC ladder interrupt ability (optional). This versatility allows for customization based on the specific requirements of the process, whether it’s a simple counting task or a more complex control operation that involves interrupt – driven actions.

Wide Input Compatibility

The 12 single – ended or differential inputs, along with support for TTL, non – TTL, and magnetic pickup input thresholds, make the GE IC697HSC700 highly compatible with a broad range of sensors and transducers. This means it can be easily integrated into existing industrial setups, regardless of the type of input signals being generated by the field devices. Whether it’s a proximity sensor, a flowmeter, or a rotary encoder, the module can effectively interface with it and accurately count the incoming pulses.

Easy Configuration

The module’s configuration process is user – friendly. By using common operating systems like MS – DOS or Windows, and communication protocols such as Ethernet TCP/IP or the SNP port, engineers can quickly configure the IC697HSC700 to suit their application. The pre – installed configuration function on the programming device simplifies the setup, reducing the time and effort required for commissioning.

IS200AEPAH1ACB

Application Field

Manufacturing Industry

In manufacturing plants, the GE IC697HSC700 is widely used for monitoring production lines. For example, in an automotive manufacturing plant, it can count the number of parts passing through a conveyor belt. The high – speed counting ability ensures that every part is accurately accounted for, even in high – volume production scenarios. It can also be used to control the speed of machinery based on the count of incoming or outgoing products. In a packaging factory, the module can precisely count the number of packages being filled or sealed, ensuring that production targets are met and quality control is maintained.

Power Generation

In power generation facilities, the IC697HSC700 can be used to monitor the rotation speed of turbines. By counting the pulses generated by sensors attached to the turbine shaft, it can accurately determine the speed and ensure that the turbine is operating within the optimal range. This is crucial for maintaining stable power generation and preventing over – or under – speed conditions that could lead to equipment damage. In wind power plants, it can count the revolutions of the wind turbine blades, helping to optimize power output based on wind speed and direction.

Material Handling

In warehouses and distribution centers, the GE IC697HSC700 is useful for tracking the movement of goods. For instance, it can count the number of pallets passing through a conveyor system or the number of packages being loaded onto trucks. This data can be used for inventory management, ensuring that the right amount of stock is available and that the supply chain operates smoothly. It can also be integrated with automated guided vehicles (AGVs) to control their movement based on the count of objects they are transporting.

Related Products

- GE IC697 series modules: Modules like the IC697CPU731 (a CPU module) work in tandem with the IC697HSC700. The CPU module processes the data received from the high – speed counter module, making decisions and sending control signals to other parts of the industrial system. While the IC697HSC700 focuses on high – speed counting and input/output handling related to counting operations, the CPU module manages the overall control logic.

- GE Series 90 – 70 communication modules: These modules, such as those with industry – standard LAN Ethernet controllers or genius bus controllers, can be used to enhance the communication capabilities of the system where the IC697HSC700 is installed. They enable the high – speed counter module to communicate with other devices in the network, allowing for data sharing and coordinated control.

- GE analog quantity I/O modules: Modules that handle analog signals, like high – density analog I/O modules for process control, can be part of the same industrial system as the IC697HSC700. In applications where both analog and digital (counting – based) data are involved, such as in some complex manufacturing processes, these analog I/O modules can work together with the high – speed counter module to provide a comprehensive control solution.

- GE discrete quantity I/O modules: These modules, which support different voltage ranges and types, can interface with the IC697HSC700 in an industrial setup. They can be used to control actuators based on the counting results from the high – speed counter module or provide additional input signals that may affect the counting operations.

- GE power modules: Specific power modules in the Series 90 – 70 range are designed to supply power to the IC697HSC700 and other modules in the system. A stable power supply is essential for the proper functioning of the high – speed counter module, and these power modules ensure that the module receives the correct voltage and current levels.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IC697HSC700, ensure that the power to the entire Series 90 – 70 system is turned off to prevent electrical hazards. Thoroughly inspect the module for any visible signs of damage during transit. Check the compatibility of the module with the existing system components, including the backplane, power supply, and other connected modules. Follow the detailed installation guidelines provided in the product manual to correctly insert the IC697HSC700 into the designated single slot. Make sure the module is firmly seated and all connections are secure to ensure reliable electrical and mechanical contact.

Maintenance recommendations: Regularly check the IC697HSC700 for any signs of overheating, such as discoloration of the module or components. Monitor the status of the LEDs on the outputs to ensure they are functioning correctly and indicating the proper output states. Periodically review the counting accuracy of the module by comparing the counted values with known reference values. If any issues are detected, refer to the product manual for troubleshooting steps. Keep the installation area clean and free from dust and debris, as these can affect the module’s performance. Also, ensure that the environmental conditions, such as temperature and humidity, are within the specified operating range of the GE IC697HSC700.

Maintenance recommendations: Regularly check the IC697HSC700 for any signs of overheating, such as discoloration of the module or components. Monitor the status of the LEDs on the outputs to ensure they are functioning correctly and indicating the proper output states. Periodically review the counting accuracy of the module by comparing the counted values with known reference values. If any issues are detected, refer to the product manual for troubleshooting steps. Keep the installation area clean and free from dust and debris, as these can affect the module’s performance. Also, ensure that the environmental conditions, such as temperature and humidity, are within the specified operating range of the GE IC697HSC700.

Product Guarantee

GE Fanuc stands firmly behind the quality of the GE IC697HSC700. The module is manufactured to meet the highest industry standards, undergoing rigorous testing procedures to ensure its reliability and performance. In the unlikely event of a defect in materials or workmanship during the warranty period, GE Fanuc offers comprehensive repair or replacement services. Their dedicated technical support team is available to assist customers with any installation – related queries, operational issues, or troubleshooting needs. This commitment to quality and customer support reflects GE Fanuc’s confidence in the IC697HSC700 and its ability to meet the demanding requirements of industrial applications, providing customers with peace of mind and long – term value.