Description

Product Overview

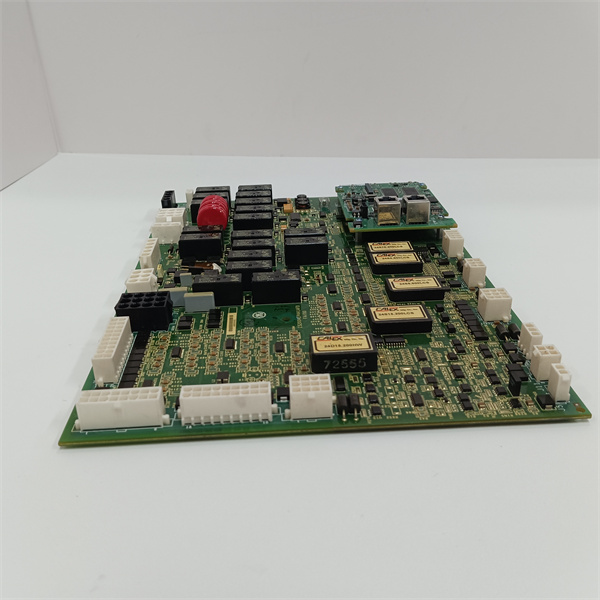

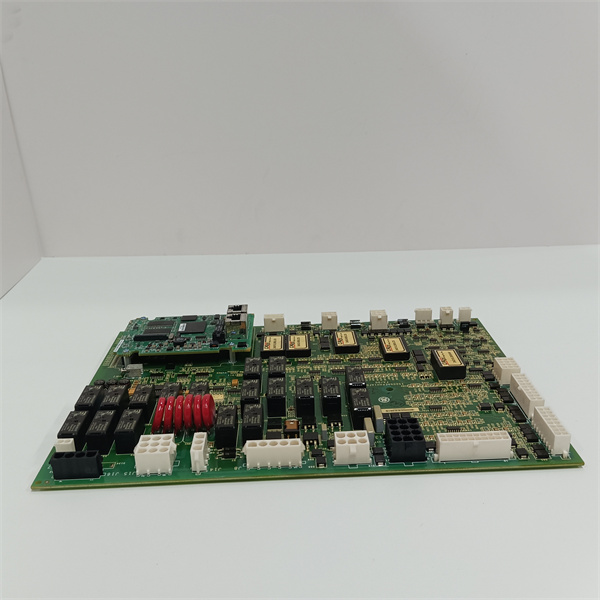

The GE IC694CHS392 is a 10 – slot serial expansion baseplate that plays a pivotal role in the PAC System RX3i programmable automation controller platform. Once produced by GE Fanuc and now under Emerson Automation, this baseplate is designed to expand the I/O capabilities of the main rack in industrial automation setups. The IC694CHS392 enables connection of additional I/O modules through an I/O expansion cable, with a maximum cable length of 15 meters (50 feet). It offers the flexibility to integrate more I/O devices into the control system, thereby enhancing the system’s overall functionality. In industrial automation, the IC694CHS392 is crucial for applications that demand modular expansion and high – speed serial communication, making it an essential component for building scalable and efficient control systems.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC694CHS392 |

| Manufacturer | GE (formerly GE Fanuc, now Emerson Automation) |

| Product Type | Serial expansion backplane |

| Number of Slots | 10 |

| Compatible Modules | Analog, discrete, or special – function modules |

| Maximum Cable Length | 15 meters (50 feet) |

| Connector Type | 25 – pin D – shell female connector |

| Mounting | Supports front and recessed panel mounting |

| Internal Power Consumption | 150 mA at 5 VDC |

| Dimensions | 5.12 x 17.44 x 5.59 in (13.00 x 44.30 x 14.20 cm) |

| Power Supply | Rated voltage 5 VDC |

IS210BPPBH2CAA

Main Features and Advantages

Ample Slot Capacity

The GE IC694CHS392 comes with 10 slots, providing sufficient space for various I/O or optional modules. Slot 1 is specifically reserved for power supply modules such as the IC694PWR331, IC694PWR330, or IC694PWR321. This allows for a modular and customizable approach to system design, enabling users to configure the I/O setup according to their specific industrial requirements.

High – Speed Serial Communication

It supports high – speed serial communication, ensuring fast and reliable data transfer between the baseplate and other components in the automation system. This is essential for applications where real – time data exchange is critical, such as in high – speed manufacturing processes or complex industrial control loops.

Compatibility and Flexibility

The baseplate is compatible with a wide range of analog, discrete, and special – function modules. This compatibility offers great flexibility in system configuration, allowing it to be tailored to different industrial applications, whether it’s for basic on – off control in a simple manufacturing line or for complex analog signal processing in a chemical plant.

Reliable Mounting Options

With support for both front and recessed panel mounting, the IC694CHS392 can be easily installed in different industrial setups. This adaptability in mounting options makes it suitable for various control cabinets and enclosures, enhancing its usability in diverse industrial environments.

Built – in Diagnostics

It has built – in diagnostics that help in quickly identifying and resolving issues. This feature reduces system downtime, as technicians can easily pinpoint problems and take corrective actions, ensuring the continuous and smooth operation of the industrial automation system.

IS200AEPAH1AFD

Application Field

Manufacturing Industry

In manufacturing plants, the GE IC694CHS392 is extensively used to expand the control system’s I/O capacity. For example, in an automotive assembly line, it can connect additional sensors and actuators. These sensors can detect the position of car parts during assembly, while the actuators can precisely control the movement of robotic arms. By expanding the I/O capabilities, the manufacturing process can be more precisely controlled, leading to higher production quality and efficiency.

Process Industry

In the process industry, such as in chemical plants or oil refineries, the IC694CHS392 is crucial. In a chemical plant, it can be used to connect more sensors for monitoring temperature, pressure, and chemical composition in reactors. Additionally, it can interface with actuators that control the flow of chemicals. The high – speed serial communication of the baseplate ensures that real – time data from these sensors can be quickly processed, and appropriate control actions can be taken to maintain optimal process conditions.

Power Generation

Power generation facilities also benefit from the IC694CHS392. In a power plant, it can expand the I/O system to connect more sensors for monitoring the performance of turbines, generators, and other equipment. For instance, sensors connected via the baseplate can measure the vibration of turbines, and actuators can adjust the speed or load based on the sensor data. This helps in ensuring the efficient and reliable operation of the power generation system.

Related Products

IC694CHS398

A 5 – slot backplane. It is related to the IC694CHS392 as it is also a serial expansion backplane in the same product family. The main difference is the number of slots, with the IC694CHS398 having fewer slots, making it suitable for applications with smaller I/O requirements.

IC693CHS392

Part of the Series 90 – 30 expansion backplane. It can be used in combination with the IC694CHS392 in some systems. It may have different compatibility features, perhaps being more suitable for integrating with older GE Fanuc systems, while the IC694CHS392 is more focused on the PAC System RX3i platform.

IC694PWR321

A power supply module. It is directly related to the IC694CHS392 as it can be installed in slot 1 of the baseplate. It provides the necessary power for the IC694CHS392 and the modules connected to it, with a power supply of 120/240 VAC, 125 VDC.

IC694PWR330

Another power supply option for the IC694CHS392. It is a high – capacity power supply, providing 120/240 VAC, 125 VDC. It is used when the system requires more power to support the operation of the baseplate and its connected I/O modules.

IC694PWR331

A high – capacity 24 VDC power supply for the IC694CHS392. It offers an alternative power option, allowing users to choose the most suitable power supply based on their specific power requirements and system setup.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IC694CHS392, carefully check the integrity of the baseplate and all its components. Ensure that the mounting location has enough space to accommodate the 10 – slot baseplate. Verify that the available power supply, such as the IC694PWR321, IC694PWR330, or IC694PWR331, is compatible with the IC694CHS392. Set the dip switch for the rack number correctly according to the system requirements before installing any modules.

Maintenance recommendations: Regularly inspect the GE IC694CHS392 for signs of physical damage or wear. Clean the baseplate and its connectors regularly to maintain good electrical contact. Check the cable connections to ensure they are secure and free from loose ends. Monitor the power supply to ensure it provides the correct voltage and current. If any issues are detected, refer to the product manual or contact the technical support team for assistance.

Maintenance recommendations: Regularly inspect the GE IC694CHS392 for signs of physical damage or wear. Clean the baseplate and its connectors regularly to maintain good electrical contact. Check the cable connections to ensure they are secure and free from loose ends. Monitor the power supply to ensure it provides the correct voltage and current. If any issues are detected, refer to the product manual or contact the technical support team for assistance.

Product Guarantee

GE (now Emerson Automation) stands firmly behind the quality of the GE IC694CHS392. The product is manufactured to the highest standards, using top – quality components. A comprehensive quality assurance program is in place to ensure that the IC694CHS392 meets all performance and reliability requirements. In case of any defects or malfunctions during the warranty period, customers can expect prompt after – sales service. The dedicated technical support team is available to assist with installation, configuration, and troubleshooting. This commitment to quality and customer service gives customers the confidence that their investment in the IC694CHS392 will result in a reliable and long – lasting solution for their industrial automation needs.