Description

Product Overview

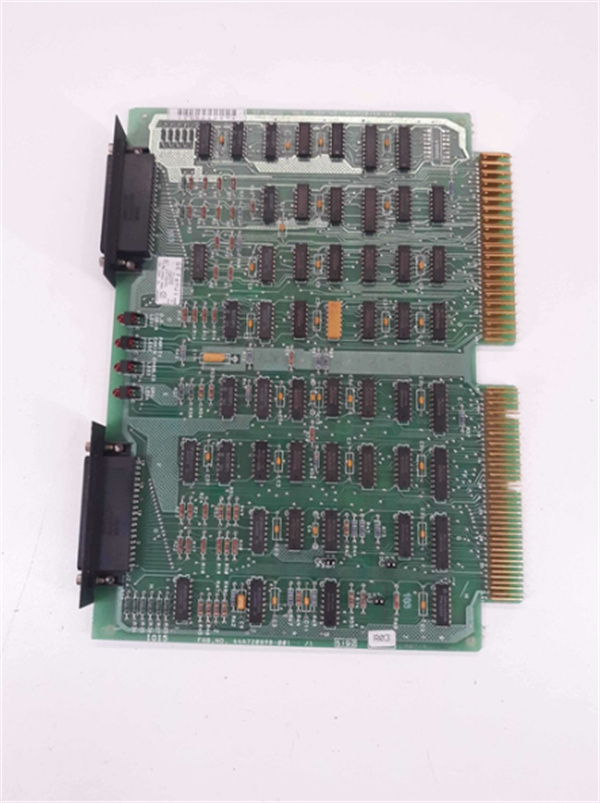

The GE IC600CB527M is a high – performance I/O control module, an integral part of GE Fanuc’s Series Six modular board product line. Engineered to offer seamless communication and control within industrial automation setups, it plays a pivotal role in diverse applications.

This module serves as a critical interface between the main input/output chain and the CPU in Series Six CPUs. It effectively manages data transfer not only between the CPU and the I/O chain but also between the CPU and peripherals like data processor units and program development terminals. In industrial control systems, the IC600CB527M is positioned as a reliable solution for enhancing system connectivity and control precision. Whether it’s a large – scale manufacturing plant or a power generation facility, this module ensures smooth operation by accurately handling input and output signals, contributing to the overall efficiency and stability of the automation system.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC600CB527M |

| Manufacturer | GE |

| Product Type | I/O Control Module |

| Power Supply | 5V DC, 1A (supplied by CPU power) |

| Operating Temperature Range | 0 – 60°C |

| Storage Temperature Range | 0 – 70°C |

| Relative Humidity | 5% – 95%, non – condensing |

| Board Dimensions | Approximately 8.15 x 11 inches |

| Panel Dimensions | Approximately 12.46 x 1.175 inches |

| LED Indicators | 4 (DPU, ENABLED, CHAIN OK, PARITY) |

| Applicable CPUs | GE 60 – type, 600 – type, 6000 – type |

IC600CB527M

Main Features and Advantages

Efficient Data Handling

The IC600CB527M is designed to efficiently handle data transfer tasks. Its role in controlling data flow between the CPU and various components ensures that information is accurately and quickly transmitted. For example, in a manufacturing assembly line where real – time monitoring of sensors and actuators is crucial, the module can rapidly relay data, enabling timely adjustments to the production process. This high – speed data handling minimizes delays and improves overall system responsiveness.

Simplified Troubleshooting

With its four LED indicators – DPU, ENABLED, CHAIN OK, and PARITY, the module simplifies the troubleshooting process. The DPU LED indicates the status of the data processor unit interface, while the ENABLED LED shows whether the module is active. The CHAIN OK LED signals the integrity of the I/O chain, and the PARITY LED helps identify parity errors in the I/O data. In case of a system malfunction, technicians can quickly refer to these LEDs to pinpoint the source of the problem, reducing downtime significantly.

Compatibility and Versatility

It is compatible with a wide range of GE CPUs, including the 60 – type, 600 – type, and 6000 – type. This compatibility allows for easy integration into existing systems, whether they are older setups that need upgrades or new installations. For instance, in a power plant that has been using GE 60 – type CPUs and wants to expand its control capabilities, the IC600CB527M can be readily installed without major system overhauls, providing versatility in system configuration.

Application Field

In manufacturing industries, the GE IC600CB527M is extensively used in automated production lines. It can interface with numerous sensors that detect product quality, machine status, and production rates. By accurately handling the input from these sensors and controlling the output to actuators such as motors and valves, it helps optimize the manufacturing process, ensuring high – quality production and efficient resource utilization.

Power generation plants also rely on the IC600CB527M for their control systems. In both fossil – fuel – based and renewable energy power plants, the module plays a role in monitoring and controlling various parameters. For example, in a gas – fired power plant, it can manage the data from sensors that monitor gas flow, temperature, and pressure, and control the operation of turbines and generators accordingly, ensuring stable power generation.

In the water treatment industry, the module is used to control the complex processes involved in water purification and distribution. It can interface with sensors that monitor water quality parameters like pH, turbidity, and chlorine levels, and control pumps, valves, and treatment equipment to ensure the production of clean and safe water.

IC600CB527M

Related Products

- IC600CB536RR: Another I/O control module from GE. It may have enhanced features or different configurations compared to the IC600CB527M, perhaps offering more advanced diagnostic capabilities or different communication protocols for specific applications.

- GE 60 – type CPU: The IC600CB527M is compatible with this CPU. The 60 – type CPU provides the computing power, and the IC600CB527M manages the I/O functions, working in tandem to control industrial processes.

- GE 600 – type CPU: Similar to the 60 – type, but with potentially higher processing power or different memory configurations. The IC600CB527M can be integrated with it, adapting to more complex control requirements in larger – scale industrial setups.

- GE 6000 – type CPU: A more advanced CPU in the GE lineup. The IC600CB527M can interface with it, enabling high – performance control in applications where large amounts of data need to be processed and controlled, such as in large – scale manufacturing plants or power grids.

- IC600CB528M: A related module in the same series. It might have variations in terms of the number of I/O channels or the type of interfaces it supports, offering alternative options for different industrial control scenarios.

Installation and Maintenance

Pre – installation preparation: Before installing the IC600CB527M, ensure that the CPU power supply is turned off. Check the compatibility of the module with the existing CPU model, whether it’s a 60 – type, 600 – type, or 6000 – type. Inspect the module for any visible damage during transit. When installing, carefully align the module with the CPU rack and secure it in place using the appropriate mounting hardware. Make sure all connections are properly made according to the wiring diagram provided in the product manual.

Maintenance recommendations: Regularly check the LED indicators on the IC600CB527M to monitor its status. If any of the LEDs show abnormal behavior, refer to the troubleshooting guide in the manual. Keep the module clean from dust and debris, as these can affect its performance. Periodically test the data transfer capabilities of the module by running diagnostic tests. If the module shows signs of malfunction, contact GE’s technical support for further assistance, and consider replacing the module if necessary to maintain the reliability of the control system.

Product Guarantee

GE stands firmly behind the quality of the IC600CB527M. The module undergoes rigorous quality control during the manufacturing process to ensure it meets high – standard industrial requirements. In case of any defects in materials or workmanship, GE provides a comprehensive after – sales service. Their technical support team is available to offer remote diagnostic services and, if needed, on – site assistance. GE also offers a warranty period during which, if the IC600CB527M fails due to quality issues, they will replace or repair the module free of charge. This commitment reflects GE’s confidence in the product’s reliability and its dedication to customer satisfaction.