Description

Detailed parameter table

| Parameter name | Parameter value |

|---|---|

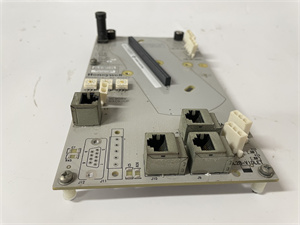

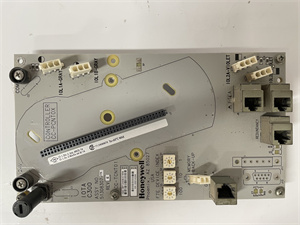

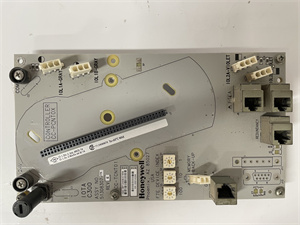

| Product model | CC – TCNT01 |

| Manufacturer | Honeywell |

| Product category | C300 Controller Input Output Termination Assembly |

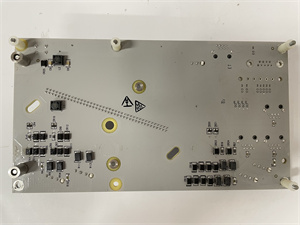

| Electrical performance | I/O supply rating: 0.311 A @ 24V DC; Rated voltage: 24 VDC; Current capacity: 0.311 A |

| Physical size | Weight: 0.22 kg (approximate, as no specific length, width, height provided in sources) |

| Interface type | Connection points for controller module and various cable terminations (FTE, IO link, redundancy, battery, time source cable terminations) |

| Communication protocol | Not prominently specified in available sources, but likely interfaces with systems in a way to support C300 controller operations |

| Environmental requirements | Operating temperature range: – 40 °C to + 70 °C; Humidity: 0% – 95%RH non – condensing; Protection level: IP20 |

| Installation method | Likely installed as part of the C300 controller setup, details not elaborated in sources |

| Performance indicators | Input type: voltage, current (2 – wire or self – powered transmitters); Input channels: 16 channels (12 single – ended / 4 differential); Input range: 0 to 5 V, 1 to 5 V, 0.4 to 2 V, 4 – 20 mA (through 250 ω); Normal mode rejection ratio, at 60 Hz: 19 dB maximum; Normal mode input: ± 30 volts; Crosstalk, DC to 60 Hz (channel – to – channel): – 60 dB; Input impedance (voltage inputs): > 10 mω; Powered maximum input voltage: ± 30 volts; Input scan rate: 50 ms; Hardware accuracy (@ cmv = 0 V): ± 0.075% of full – scale (23.5 ° ± 2 °C), ± 0.15% of full – scale (0 to 60 °C); Transmitter field power conditioning: individually protected current limiting circuits for class 1, div 2 non – incendive interfacing. No fusing required |

| Power distribution | Provides 24V DC power distribution to the controller module |

Honeywell CC-TCNT01

Product introduction

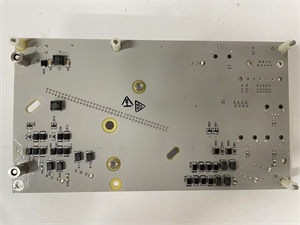

The Honeywell CC – TCNT01 is a crucial component within the realm of industrial automation, specifically designed as an input output termination assembly for the C300 controller. As part of Honeywell’s comprehensive automation solutions, the CC – TCNT01 plays a pivotal role in ensuring seamless connectivity and efficient operation within the C300 controller platform.

This module serves as the connection hub for the C300 controller module and all associated cable terminations. It manages connections related to field termination equipment (FTE), IO link, redundancy, battery, and time source cables. Additionally, it is responsible for distributing 24V DC power to the controller module. In an industrial automation system, the CC – TCNT01 acts as a linchpin, facilitating the smooth transfer of signals and power, which is essential for the overall performance and reliability of the system. Whether in a large – scale manufacturing plant or a complex industrial process control setup, the CC – TCNT01 from Honeywell is designed to meet the demands of modern industrial automation.

Core advantages and technical highlights

Robust connectivity

The CC – TCNT01 offers extensive connectivity options. Its ability to interface with multiple types of cable terminations such as FTE, IO link, and more ensures that it can be integrated into diverse industrial setups. This wide – ranging connectivity simplifies the process of building and maintaining an industrial control system, as it can accommodate different types of devices and communication channels. For example, in a manufacturing facility with a mix of legacy and new – generation equipment, the CC – TCNT01 can bridge the communication gap between various components, enabling efficient data transfer and control.

Precise signal handling

With 16 input channels, including 12 single – ended and 4 differential, the CC – TCNT01 is well – equipped to handle a variety of input signals. It supports different input ranges such as 0 to 5 V, 1 to 5 V, 0.4 to 2 V, and 4 – 20 mA (through 250 ω). The module also has impressive signal – related performance metrics. It can reject normal – mode interference up to 19 dB at 60 Hz and has a crosstalk of – 60 dB from DC to 60 Hz between channels. This precise signal handling ensures that the data received and processed is accurate, which is crucial for making informed control decisions in industrial processes.

Reliable power distribution

Supplying 24V DC power to the controller module, the CC – TCNT01 ensures stable power delivery. The individually protected current – limiting circuits for non – incendive interfacing add an extra layer of safety and reliability. In industrial environments where power fluctuations and electrical hazards are common, the CC – TCNT01‘s power – related features help safeguard the controller and connected devices. This reliable power distribution is vital for maintaining continuous operation of the industrial control system, reducing the risk of downtime due to power – related issues.

Honeywell CC-TCNT01

Typical application scenarios

Oil and gas industry

In oil refineries and gas processing plants, the Honeywell CC – TCNT01 is used to connect a multitude of sensors and control devices. These sensors monitor crucial parameters like temperature, pressure, and flow rates. The CC – TCNT01 efficiently manages the input signals from these sensors and distributes power to the relevant controller modules. For example, in a crude oil distillation unit, the module ensures that the signals from temperature sensors are accurately transmitted to the controller. This enables precise control of the distillation process, optimizing product quality and energy efficiency. The reliable power distribution feature also ensures that the control system operates without interruption, even in the harsh and potentially explosive environments typical of the oil and gas industry.

Manufacturing

In manufacturing facilities, the CC – TCNT01 is employed in various production lines. It can be used to connect robots, automated machinery, and sensors. For instance, in an automotive manufacturing plant’s assembly line, the module links the sensors that detect the position of car parts to the controller. This allows for accurate control of robotic arms during the assembly process. The wide range of input channels and robust connectivity of the CC – TCNT01 make it suitable for handling the complex network of devices in a manufacturing environment. It ensures seamless communication and control, leading to increased production efficiency and reduced errors.

Power generation

Power plants, whether they are coal – fired, gas – fired, or renewable energy – based, rely on the CC – TCNT01 for their control systems. It connects sensors that monitor parameters such as steam pressure in a thermal power plant or wind speed in a wind farm to the central controller. The module’s precise signal handling capabilities are crucial for ensuring that the power generation process is stable and efficient. In a thermal power plant, accurate monitoring of steam pressure through the CC – TCNT01 – connected sensors helps in optimizing the turbine operation, thereby maximizing power output and minimizing fuel consumption.

Related model recommendations

- CC – TAIN01: It is likely part of the same family as the CC – TCNT01 within Honeywell’s product lineup. While the CC – TCNT01 focuses on input output termination and power distribution for the C300 controller, the CC – TAIN01 might be more specialized in analog input functions. They can be used together in an industrial control system, with the CC – TAIN01 feeding analog input signals that the CC – TCNT01 can then manage in the context of the overall C300 controller operations.

- CC – TAON01: This model could be related in terms of being an output – related module for the C300 controller system. Similar to how the CC – TCNT01 manages terminations and power for the controller, the CC – TAON01 might be responsible for outputting control signals to actuators. In a complete industrial automation setup, the CC – TCNT01 and CC – TAON01 can work in tandem, with the CC – TCNT01 handling the input side and power distribution, and the CC – TAON01 taking care of the output to drive industrial processes.

- CC – PAIM01: It may have a complementary role to the CC – TCNT01. While the CC – TCNT01 is centered around the C300 controller’s input output termination, the CC – PAIM01 might be involved in more complex control functions, perhaps related to process control algorithms. In an industrial system, the CC – TCNT01 can provide the necessary connectivity and basic signal handling, and the CC – PAIM01 can use the processed signals from the CC – TCNT01 to perform advanced control operations.

- CC – PDOB01: This is likely a digital output module. In an industrial control setup, the CC – TCNT01 can manage the input side of the C300 controller, and the CC – PDOB01 can be used to output digital control signals based on the data processed through the CC – TCNT01. For example, in a manufacturing process where digital signals are required to control relays or solenoids, the CC – TCNT01 can handle the input signals from sensors, and the CC – PDOB01 can be used to output the appropriate control signals to actuate the devices.

- CC – PDIL01: A digital input module, it can work in concert with the CC – TCNT01. The CC – TCNT01 manages overall input output termination and power for the C300 controller, and the CC – PDIL01 can specifically handle digital input signals. In an industrial environment with a mix of analog and digital sensors, the CC – TCNT01 can interface with the analog sensors and manage the overall system, while the CC – PDIL01 can handle the digital sensor inputs, providing a comprehensive input solution for the industrial control system.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the Honeywell CC – TCNT01, select an installation location that is clean, dry, and within the specified temperature range of – 40 °C to + 70 °C. Ensure that the area has proper ventilation to prevent overheating. Gather the necessary tools, which may include screwdrivers and cable – handling tools. Carefully inspect the CC – TCNT01 for any physical damage during transit. When installing, follow the detailed wiring diagrams provided in the product documentation. Make sure to connect the power supply (24V DC) correctly, observing the proper polarity. All cable terminations should be made securely to avoid loose connections that could lead to signal interference or power issues.

Maintenance suggestions

Regularly check the physical condition of the CC – TCNT01 for signs of wear, corrosion, or loose connections. Monitor the power supply voltage to ensure it remains stable at 24V DC. Check the input signals to ensure they are within the expected ranges as specified in the module’s technical parameters. In case of any abnormal behavior, refer to the troubleshooting guide in the product manual. If a component needs replacement, use only genuine Honeywell spare parts to maintain the integrity and performance of the module. Periodically clean the module to remove dust and debris, as this can affect its performance over time, especially in dusty industrial environments.

Service and guarantee commitment

Honeywell stands firmly behind the CC – TCNT01 with a comprehensive service and guarantee commitment. The module comes with a standard warranty, which safeguards against defects in materials and workmanship. Honeywell’s global network of technical support teams is available around the clock. Whether it’s assistance during the installation phase, troubleshooting complex issues, or providing advice on system integration, these experts are just a call away. The company also offers regular software updates and product enhancements to ensure that the CC – TCNT01 continues to perform optimally in evolving industrial environments. This commitment to service and quality assurance reflects Honeywell’s confidence in the reliability and durability of the CC – TCNT01, giving customers peace of mind when integrating it into their critical industrial automation systems.