Description

Detailed parameter table

|

Parameter name

|

Parameter value

|

|

Product model

|

CC – PAOX01

|

|

Manufacturer

|

Honeywell

|

|

Product category

|

Analog Output Module

|

|

Input voltage

|

24VDC

|

|

Output voltage

|

24VDC

|

|

Output channels

|

4 isolated channels

|

|

Communication interface

|

Supports HART protocol, may have Ethernet and RS485

|

|

Accuracy

|

High – precision for stable output

|

|

Output type

|

Analog (0 – 10V voltage or 4 – 20mA current)

|

|

Operating temperature range

|

– 40°C to + 85°C

|

|

Installation method

|

DIN – rail or panel mount

|

|

Dimensions (approx.)

|

30cm×20cm×20cm

|

|

Weight (approx.)

|

2kg

|

|

Certifications

|

CE, UL (possibly others)

|

Honeywell CC-PAOX01

Product introduction

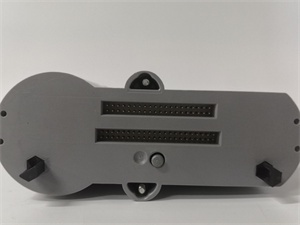

The Honeywell CC – PAOX01 is a sophisticated analog output module, carefully crafted for industrial automation control applications. As a part of Honeywell’s extensive portfolio of industrial control products, it stands out for its high – performance capabilities.

This module serves as a crucial link in the automation system. Its core function is to convert digital signals from the control system into accurate analog signals for external devices. For instance, it can precisely control the operation of actuators and sensors. By receiving digital commands from the control system, the CC – PAOX01 module outputs corresponding analog signals, which can adjust the opening degree of control valves, regulate the speed of motors, and more. In an industrial production line, this accurate control is essential for maintaining the stability and efficiency of the production process. It enables seamless integration with other components of the automation system, making it an indispensable part for achieving smooth and reliable industrial automation.

Core advantages and technical highlights

High – precision output

The Honeywell CC – PAOX01 is engineered to provide high – precision analog output. It employs advanced manufacturing techniques and top – quality electronic components. This ensures that even in harsh industrial environments, such as those with high temperatures, humidity, or strong electromagnetic interference, the module can output signals with minimal deviation. In industries like chemical manufacturing, where precise control of parameters like temperature, pressure, and flow rate is critical, the high – precision output of the CC – PAOX01 helps maintain the optimal reaction conditions, thus improving product quality and production safety.

Versatile output types

Featuring multiple output types, including common analog voltage (0 – 10V) and current (4 – 20mA) outputs, the CC – PAOX01 offers great flexibility. This allows it to be easily adapted to different industrial devices. Some actuators may require voltage signals for operation, while others work better with current signals. The CC – PAOX01 can meet these diverse requirements, enhancing its compatibility and applicability in complex industrial automation setups.

HART communication support

Equipped with HART communication protocol capabilities, the CC – PAOX01 enables advanced diagnostic functions and convenient remote configuration. Through HART communication, operators can remotely monitor the module’s operating status in real – time, such as the accuracy of output signals and the health of the device. In case of any abnormalities, the system can quickly issue alerts and perform fault diagnosis and parameter adjustment via HART communication, eliminating the need for on – site maintenance in many cases. This significantly improves maintenance efficiency and reduces maintenance costs, especially in large – scale industrial plants where on – site access may be difficult or time – consuming.

Compact design and easy installation

The module’s compact design makes it space – saving, facilitating installation in cabinets or equipment with limited space. Whether installed using the DIN – rail method or panel – mount method, the process is straightforward and quick. This design is particularly beneficial in industrial automation projects with strict space constraints, such as small – scale automated production lines or distributed control system field control units, where the CC – PAOX01 can be easily integrated without taking up excessive space.

Robust and durable for harsh environments

Designed to endure harsh industrial conditions, the CC – PAOX01 has a rugged enclosure and special protection measures. It can resist dust, moisture, vibration, and electromagnetic interference. With an operating temperature range from – 40°C to + 85°C, it can function reliably in extreme cold or hot industrial settings. For example, in outdoor chemical facilities in northern winters or steel smelting workshops in southern summers, the CC – PAOX01 can consistently perform its analog output tasks, ensuring the continuous and stable operation of industrial production regardless of environmental challenges.

Honeywell CC-PAOX01

Typical application scenarios

Chemical industry

In the chemical industry, the Honeywell CC – PAOX01 plays a vital role. In the production of synthetic ammonia, it can convert digital signals from the control system into analog signals to precisely regulate key parameters such as the temperature, pressure, and material flow rate in the synthesis tower. Precise control of these parameters optimizes the reaction efficiency, reduces energy consumption, and ensures product quality consistency. During the transportation of chemical raw materials, the module can control the speed of pumps and the opening of valves, accurately regulating the material flow rate and preventing production accidents or quality issues caused by improper flow.

Power industry

In power generation plants, the CC – PAOX01 is extensively used. In a thermal power plant’s boiler combustion system, it can adjust the fuel supply and combustion air ratio according to control system commands, achieving efficient and stable combustion, improving power generation efficiency, and reducing pollutant emissions. In a hydropower plant, the module can control the opening of the turbine guide vanes, adjust the water flow rate, and thus control the turbine speed and power generation, ensuring stable and reliable power supply. In the power grid’s reactive power compensation system, the CC – PAOX01 can control the switching of capacitor banks, adjust the power factor of the grid, and improve power quality.

Steel and metallurgy industry

Within the steel production process, the CC – PAOX01 is indispensable. In the blast furnace iron – making process, it can accurately control the temperature and blast volume of the hot blast stove, ensuring that the iron ore in the blast furnace can be smelted under the optimal reduction conditions, increasing the output and quality of molten iron. During the steel – making process, the module can control the tilting angle of the converter, the lifting of the oxygen lance, and the oxygen blowing volume, precisely controlling the steel – making process to produce steel products that meet different quality standards. In the steel rolling process, the CC – PAOX01 can adjust the rolling force and speed of the rolling mill, ensuring the dimensional accuracy and surface quality of the steel.

Pharmaceutical industry

In the pharmaceutical production process, which requires strict control of environmental parameters and production equipment, the CC – PAOX01 is crucial. In the clean air – conditioning system of a pharmaceutical production workshop, it can adjust the fan speed, valve opening, and humidifier water spray volume of the air – conditioning unit according to the control system’s instructions, precisely controlling environmental parameters such as temperature, humidity, air flow rate, and cleanliness in the workshop, providing an environment that meets GMP (Good Manufacturing Practice) requirements for pharmaceutical production. For pharmaceutical production equipment such as reactors and filling machines, the module can accurately control the operating parameters of the equipment, ensuring the consistency and stability of the pharmaceutical production process and the reliability of pharmaceutical product quality.

Related model recommendations

CC – PAOH01

This model, also from Honeywell, is similar to the CC – PAOX01 but with enhanced HART protocol capabilities. It offers more advanced device diagnosis and two – way communication features. It is an ideal choice for applications that demand in – depth remote monitoring, detailed fault diagnosis, and real – time parameter adjustment, such as in large – scale chemical complexes where comprehensive management of analog output devices is required.

CC – PAIX01

The CC – PAIX01 is an analog input card. It complements the CC – PAOX01 as it is responsible for collecting analog signals from field sensors (such as temperature, pressure, and flow sensors) and converting them into digital signals for the control system. Together, they form a complete input – output loop in an industrial automation control system. In an automated production line monitoring and control project, the CC – PAIX01 collects various equipment operation parameters, while the CC – PAOX01 controls the execution equipment based on the control system’s commands, ensuring the efficient operation of the production line.

CC – PDIL01

As a digital input card, the CC – PDIL01 is used to receive digital signals from the field, such as switch statuses and proximity switch signals. In industrial automation systems, in addition to handling analog signals, a large number of digital signals also need to be processed. The CC – PDIL01 can co – exist with the CC – PAOX01 in the same control system, with the former handling digital input tasks and the latter handling analog output tasks. For example, in an automated warehousing system, the CC – PDIL01 can collect information such as the presence or absence of goods on the shelves and the position of stacker cranes, while the CC – PAOX01 controls the motor speed of conveyor equipment and the operation of sorting devices, jointly enabling the intelligent operation of the automated warehousing system.

CC – PAOX02

The CC – PAOX02 may be an upgraded version of the CC – PAOX01. It could have improvements in terms of output accuracy, communication speed, or additional functionality. For applications with higher – level requirements for analog output performance, such as in precision manufacturing processes where extremely accurate control of actuators is necessary, the CC – PAOX02 might be a more suitable option.

CC – PAOX01R

The “R” in the model might indicate redundancy features. The CC – PAOX01R is designed for applications where high availability is critical, like in aerospace or nuclear power industries. In these industries, system downtime can have severe consequences. The redundant design of the CC – PAOX01R ensures that in case of a component failure, the module can still function properly, minimizing the risk of system failures and ensuring continuous operation.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the Honeywell CC – PAOX01 module, ensure the installation environment temperature is within the range of – 40°C to + 85°C. Prepare appropriate installation tools, such as screwdrivers and wrenches, for module fixation and cable connection. Always disconnect the power supply of the entire control system before installation to prevent electrical accidents. Thoroughly inspect the module’s appearance for any damage or deformation, and confirm that the module model matches the actual application requirements. Select the appropriate installation method (DIN – rail or panel – mount) based on the installation space and system layout, and plan the module’s installation position in the control cabinet or equipment in advance to ensure firm installation and easy subsequent maintenance and inspection. Also, prepare cables that meet the specified requirements for connecting the module’s input, output, and communication interfaces. The cable specifications should be selected according to factors such as signal type, transmission distance, and current load.

Maintenance suggestions

Regularly conduct visual inspections of the CC – PAOX01 module. Check if the module’s enclosure has any damage or deformation, if the connection terminals are loose or oxidized, and if there is any dust or oil contamination on the module surface. If dust or oil is present, gently wipe the module with a clean soft cloth to keep it clean, as contaminants can affect heat dissipation and electrical performance. Periodically use professional testing tools to detect the accuracy of the module’s output signals and compare the results with the initial commissioning data to determine if the output accuracy has changed. If the accuracy deviation exceeds the allowable range, calibrate the module in a timely manner or check for hardware failures. Pay special attention to the module’s operating temperature during maintenance to avoid long – term operation in high – temperature or low – temperature environments. If the module’s operating temperature is abnormally high, check if the surrounding environment has good ventilation and if there are other heat – generating devices affecting the module. Take cooling measures or adjust the module’s installation position if necessary. Additionally, regularly test the module’s communication function to ensure stable and reliable communication with the control system and other devices. If a communication failure occurs, check if the communication cable is damaged, if the communication interface is loose, and if the communication parameter settings are correct. When replacing module components, always use original Honeywell parts to ensure the module’s performance and reliability. Keep detailed maintenance records, including maintenance time, content, problems found, and solutions, for future reference.

Service and guarantee commitment

Honeywell offers a comprehensive service and guarantee for the CC – PAOX01 module. Usually, the module comes with a standard warranty period, during which Honeywell will be responsible for free repair or replacement in case of malfunctions due to manufacturing defects. Honeywell has a global network of professional and efficient technical support teams. No matter where users are in the world, they can contact Honeywell’s technical support staff at any time when encountering problems related to module installation, commissioning, use, or maintenance. The technical support team will provide detailed and accurate solutions promptly. Honeywell also continuously focuses on product performance optimization and technological upgrades, regularly providing users with software updates, operation manual revisions, and other services. This ensures that the CC – PAOX01 module can always meet the evolving needs of industrial automation technology, demonstrating Honeywell’s confidence in product quality and its strong commitment to users for long – term and stable product use.