Description

Product Overview

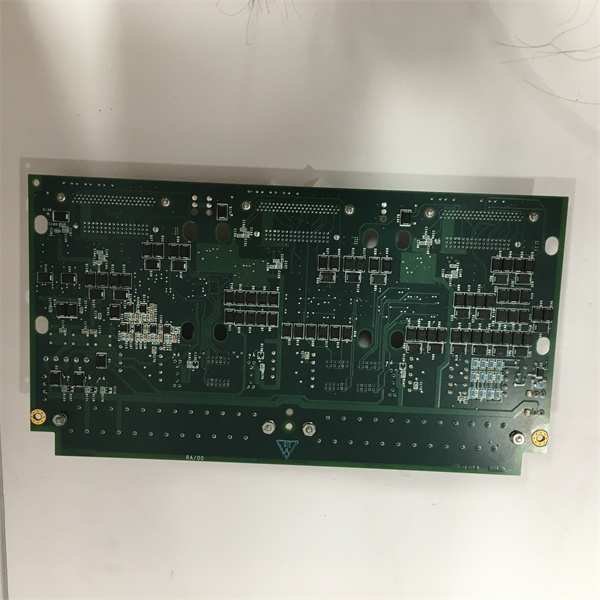

The GE HE693STP104AX is a highly advanced programmable motion control selective module, specifically designed for the GE Fanuc Series 90 – 30 programmable logic controller (PLC). In the realm of industrial automation, it plays a crucial role in enhancing the control capabilities related to stepper motors. Acting as a programmable indexer within a stepper motor control system, the GE HE693STP104AX can interface with a diverse range of stepper motor translator drives, limit switches, and encoder feedback devices. This allows for seamless integration within complex industrial setups. Its design caters to applications that demand precise motion control, making it an ideal choice for industries seeking to optimize their automated processes. Whether it’s in a manufacturing plant for controlling the movement of robotic arms or in a packaging facility for ensuring accurate product placement, the GE HE693STP104AX provides the necessary motion control solutions.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|

Product Model

|

HE693STP104AX

|

|

Manufacturer

|

GE

|

|

Product Type

|

Programmable Motion Control Selective Module

|

|

Series

|

GE Fanuc Series 90 – 30

|

|

I/O Connector – +5V Power Output (Step/Direction)

|

-300 mA

|

|

I/O Connector – Step Outputs Frequency

|

DC 245 kHz

|

|

I/O Connector – Step Outputs High (-20 mA)

|

2.5 VDC

|

|

I/O Connector – Step Outputs Low (-20 mA)

|

-0.5 VDC

|

|

I/O Connector – Direction Output Setup Time

|

2 ms

|

|

I/O Connector – Direction Output High (-20 mA)

|

2.5 VDC

|

|

I/O Connector – Direction Output Low (+20 mA)

|

-0.5 VDC

|

|

I/O Connector – Encoder Input Frequency

|

DC 1.0 MHz

|

|

I/O Connector – Encoder Single – Ended Threshold

|

1.2 – 1.6 VDC

|

|

Power Load – +5VDC (Logic)

|

200 – 500 mA

|

|

Operating Temperature

|

0 – 60 °C

|

|

Storage Temperature

|

-40 – 85 °C

|

|

Relative Humidity

|

5 – 95 % rh, non – condensing

|

|

Dimensions

|

2.1 cm x 20.2 cm x 26.1 cm

|

|

Weight

|

0.27 kg

|

Main Features and Advantages

High – Performance Motion Control

The GE HE693STP104AX offers a high maximum step rate and wide dynamic range position control. This enables it to be compatible with micro – stepping translator drives, ensuring smooth and quiet operation. For applications where precision in movement is critical, such as in high – end manufacturing processes, this feature ensures that the stepper motors can be controlled with utmost accuracy.

Versatile Connectivity

It has the ability to interface with a wide variety of stepper motor translator drives, limit switches, and encoder feedback devices. This versatility allows for seamless integration into different industrial setups, regardless of the specific components used in the existing system. It can adapt to various configurations, making it a flexible choice for different automation projects.

Programmable Functionality

Users can easily configure the motion of the module according to specific application requirements. This programmability means that it can be customized for different tasks, whether it’s a simple linear movement or a complex multi – axis motion. It provides the flexibility needed to meet the diverse needs of industrial automation, from basic conveyor belt control to intricate robotic arm movements.

Application Field

Factory Automation

In factory settings, the GE HE693STP104AX is extensively used to control the movement of automated machinery. For example, it can be used to precisely control the movement of robotic arms on an assembly line. By accurately positioning the robotic arms, it ensures that parts are assembled correctly, improving the overall quality and efficiency of the production process.

Packaging and Labeling

In the packaging and labeling industry, precise motion control is crucial. The GE HE693STP104AX can be used to control the movement of packaging machines, ensuring that products are packaged accurately and labels are applied in the right position. This helps in reducing product waste and improving the overall packaging process.

Material Handling

In material handling systems, such as conveyor belts and automated storage and retrieval systems, the GE HE693STP104AX can be used to control the movement of materials. It can ensure that products are moved smoothly and precisely, optimizing the efficiency of the material handling process and reducing the risk of product damage.

Related Products

HE693STP104A

Similar to the GE HE693STP104AX, it is also a motion control module for the GE Fanuc Series 90 – 30. However, it may have some differences in terms of features or performance, perhaps a slightly different version in terms of programming capabilities or compatibility with certain types of stepper motors.

GE Fanuc Series 90 – 30 PLCs

These are the programmable logic controllers with which the GE HE693STP104AX is designed to work. The PLCs provide the overall control logic, and the GE HE693STP104AX specifically handles the motion control aspects, working in tandem to automate industrial processes.

Stepper Motor Translator Drives Compatible with HE693STP104AX

There are various translator drives that can be connected to the GE HE693STP104AX. These drives receive signals from the module and translate them into the appropriate electrical signals to drive the stepper motors, each with its own specifications and performance characteristics.

Limit Switches for HE693STP104AX Applications

Limit switches are often used in conjunction with the GE HE693STP104AX to define the boundaries of motion. They can be connected to the module, and when activated, they send signals to the module to stop or change the direction of the stepper motor’s movement.

Encoder Feedback Devices for HE693STP104AX

These devices are used to provide feedback on the position and speed of the stepper motor to the GE HE693STP104AX. They help in ensuring accurate motion control by allowing the module to adjust the motor’s operation based on the real – time feedback received.

Installation and Maintenance

Pre – installation preparation: Before installing the GE HE693STP104AX, carefully read the installation manual provided by GE. Ensure that the host GE Fanuc Series 90 – 30 PLC is powered off. The module can be placed in any I/O module slot of the GE Fanuc Series 90 – 30 model 311, 321, or 331. Check the compatibility of all the components that will be connected to the module, such as stepper motor translator drives, limit switches, and encoder feedback devices. Make sure that the electrical connections are properly rated and that the installation environment meets the specified temperature and humidity requirements.

Maintenance recommendations: Regularly inspect the GE HE693STP104AX for any signs of physical damage, such as cracks or loose connections. Check the module’s performance by monitoring the motion control of the stepper motors. If there are any irregularities in the movement, it could indicate a problem with the module. Clean the module periodically to remove dust and debris, as these can affect its performance. If any faults are detected, refer to the troubleshooting guide in the manual or contact GE’s technical support for assistance.

Product Guarantee

GE stands firmly behind the quality of the GE HE693STP104AX. The product typically comes with a standard warranty period, during which any defects in materials or workmanship will be rectified by GE at no cost to the customer. Their global technical support team is available to provide assistance with installation, operation, and troubleshooting. Whether it’s helping with the initial setup, answering questions about programming the module, or resolving complex issues related to motion control, GE’s experts are committed to ensuring the optimal performance of the GE HE693STP104AX. This strong product guarantee reflects GE’s confidence in the reliability and durability of the module, giving customers peace of mind when integrating it into their industrial automation systems.