Description

Product Overview

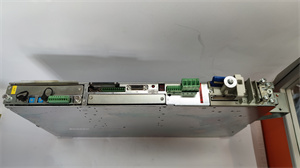

In the complex landscape of industrial control systems, the GE IS215ACLEH1BB stands as a highly significant application control layer module. As part of GE’s advanced offerings, this module plays a crucial role within the Mark VI series, which is widely recognized for its effectiveness in industrial turbine management. The IS215ACLEH1BB is designed to be a central hub for managing various applications related to the control and operation of turbines. It acts as the bridge between different components in the system, ensuring seamless communication and coordination. With a powerful 486 100MHz processor at its core, it can handle complex tasks such as implementing control logic for turbine speed, load, and temperature regulation. This module is an essential part of maintaining the overall efficiency, safety, and smooth operation of the entire turbine control system, making it a go – to solution for industries relying on turbine – based processes.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IS215ACLEH1BB |

| Manufacturer | GE |

| Product Type | Application Control Layer Module |

| Series | Mark VI |

| Processor | 486 100MHz |

| Ethernet Interface | 10BaseT |

| Output Voltage | 24 V dc |

| Operating Temperature | 0 – 45 °C |

| Dimensions (Height x Width) | 15.9 cm high x 10.2 cm wide |

| Memory (Flash) | 4 MB |

| Cache Level (L2) | 128 kb |

| Communication Interfaces | Two serial ports (COM1 and COM2) |

| Mounting Style | Designed for GE’s standard VME rack mounting structure |

IS215ACLEH1BB

Main Features and Advantages

High – Performance Processing: The GE IS215ACLEH1BB is powered by a 486 100MHz processor, enabling it to execute complex control algorithms rapidly. This high – speed processing is crucial for real – time adjustment of turbine operations. For example, it can quickly respond to changes in load demands and adjust the turbine’s speed and fuel supply accordingly, optimizing energy efficiency.

Rich Communication Capabilities: Equipped with a 10BaseT Ethernet interface and two serial communication ports (COM1 and COM2), it can communicate with a wide range of devices. It can interface with sensors, actuators, and other control modules within the turbine system, as well as external systems for remote monitoring and control. This versatility allows for seamless integration into existing industrial networks.

Reliable Memory Configuration: With 4 MB of flash memory and a 128 kb L2 cache, the module can store important control programs and data securely. The flash memory ensures non – volatile storage, meaning data is retained even during power outages. The cache, managed by the PCI controller, speeds up data access, enhancing overall system performance.

User – Friendly Design: Its front – panel layout is intuitive, with four function LEDs, eight state LEDs, and four ISBus LEDs, providing clear visual indications of the module’s status. There is also a reset switch for easy troubleshooting, and the 10BaseT Ethernet and COM connectors are easily accessible, facilitating installation and maintenance.

Rich Communication Capabilities: Equipped with a 10BaseT Ethernet interface and two serial communication ports (COM1 and COM2), it can communicate with a wide range of devices. It can interface with sensors, actuators, and other control modules within the turbine system, as well as external systems for remote monitoring and control. This versatility allows for seamless integration into existing industrial networks.

Reliable Memory Configuration: With 4 MB of flash memory and a 128 kb L2 cache, the module can store important control programs and data securely. The flash memory ensures non – volatile storage, meaning data is retained even during power outages. The cache, managed by the PCI controller, speeds up data access, enhancing overall system performance.

User – Friendly Design: Its front – panel layout is intuitive, with four function LEDs, eight state LEDs, and four ISBus LEDs, providing clear visual indications of the module’s status. There is also a reset switch for easy troubleshooting, and the 10BaseT Ethernet and COM connectors are easily accessible, facilitating installation and maintenance.

Application Field

The GE IS215ACLEH1BB finds extensive use in the power generation industry. In gas and steam turbine power plants, it plays a pivotal role in controlling turbine operations. It monitors and adjusts parameters like turbine speed, load distribution, and temperature to ensure optimal power generation. For instance, it can balance the load between multiple turbines in a power plant, maximizing overall efficiency.

In the oil and gas industry, this module is used in turbine – driven compressors and pumps. It controls the speed and performance of these turbines, ensuring the efficient transportation of oil and gas. By precisely regulating the operation of turbines, it helps in reducing energy consumption and minimizing maintenance requirements.

Chemical plants also rely on the IS215ACLEH1BB for their turbine – based processes. It can manage the turbines used in chemical reactions, ensuring that the process runs smoothly and safely. It enforces safety protocols, such as emergency shutdown procedures in case of abnormal conditions, protecting the plant and its workers.

In the oil and gas industry, this module is used in turbine – driven compressors and pumps. It controls the speed and performance of these turbines, ensuring the efficient transportation of oil and gas. By precisely regulating the operation of turbines, it helps in reducing energy consumption and minimizing maintenance requirements.

Chemical plants also rely on the IS215ACLEH1BB for their turbine – based processes. It can manage the turbines used in chemical reactions, ensuring that the process runs smoothly and safely. It enforces safety protocols, such as emergency shutdown procedures in case of abnormal conditions, protecting the plant and its workers.

IS215ACLEH1BB

Related Products

- GE IS215ACLAH1A: An earlier module in the same application control layer series. It has been largely replaced by the IS215ACLEH1BB. The IS215ACLAH1A might have had less processing power or fewer communication capabilities compared to the more advanced IS215ACLEH1BB.

- GE IS200ACLEH1A: Belonging to a different product line within GE’s offerings, it serves a similar function but may be designed for different scale or specific – application requirements. It could have different form factors or interface options, making it suitable for applications where the IS215ACLEH1BB may not be the best fit.

- GE IS420UCSBH1A: A controller module that can work in tandem with the IS215ACLEH1BB in a Mark VI system. While the IS215ACLEH1BB focuses on application – level control, the IS420UCSBH1A may handle other aspects like system – level logic execution, and together they can form a comprehensive control solution.

- GE IS215VCMIH2BB: A VME bus master controller board. It can communicate with the IS215ACLEH1BB in a turbine control system setup. The IS215VCMIH2BB is more about bus management and communication between different boards in the rack, complementing the application – control functions of the IS215ACLEH1BB.

- GE IS200TURNB1A: This module may be involved in the turbine control process, perhaps focusing on turbine – specific operations such as torque control or rotational speed monitoring. It can interact with the IS215ACLEH1BB to ensure coordinated and accurate turbine control.

Installation and Maintenance

Pre – installation preparation: Before installing the GE IS215ACLEH1BB, ensure that the VME rack where it will be mounted is clean and free of dust or debris. Check the power supply to the rack to confirm it meets the module’s requirements. Verify that the communication cables, such as Ethernet and serial cables, are in good condition and properly sized. When handling the module, use proper electrostatic discharge (ESD) protection, like wearing an ESD wrist strap, to prevent damage to its sensitive components.

Maintenance recommendations: Regularly inspect the IS215ACLEH1BB for any signs of physical damage, such as cracks on the circuit board or loose connectors. Monitor the status LEDs on the front panel to quickly identify any operational issues. Clean the module periodically to remove accumulated dust, as excessive dust can affect heat dissipation and performance. Update the module’s firmware as recommended by GE to benefit from the latest bug fixes and performance improvements. If any problems arise, refer to the product manual for detailed troubleshooting steps or contact GE’s technical support for assistance.

Maintenance recommendations: Regularly inspect the IS215ACLEH1BB for any signs of physical damage, such as cracks on the circuit board or loose connectors. Monitor the status LEDs on the front panel to quickly identify any operational issues. Clean the module periodically to remove accumulated dust, as excessive dust can affect heat dissipation and performance. Update the module’s firmware as recommended by GE to benefit from the latest bug fixes and performance improvements. If any problems arise, refer to the product manual for detailed troubleshooting steps or contact GE’s technical support for assistance.

Product Guarantee

GE offers a comprehensive product guarantee for the GE IS215ACLEH1BB. The company ensures that the module is free from defects in materials and workmanship. With a dedicated team of experts, GE provides reliable after – sales service. In case of any product – related issues within the warranty period, they will promptly offer repair or replacement services. Their commitment to quality is further demonstrated by continuous product improvement and regular firmware updates. Customers can rely on GE’s reputation and support, knowing that the IS215ACLEH1BB is backed by a company with extensive experience in industrial control systems, providing peace of mind for industrial applications.