Description

Product Overview

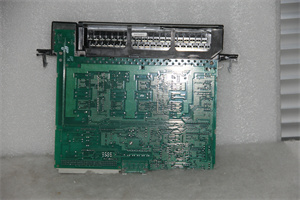

The GE IC697ALG440 is a high – performance analog input module crafted by General Electric, designed to be a cornerstone in industrial automation control systems. It is an integral part of the esteemed GE Series 90 – 30 platform, which has long been trusted in industrial settings for its reliability and versatility.

This module serves as a crucial interface between analog sensors in the field and the programmable logic controller (PLC) or other control devices. With 16 individually configurable current or voltage differential inputs, it can accommodate a wide range of analog signals. Whether it’s measuring the output of temperature sensors, pressure transducers, or flow meters, the IC697ALG440 ensures accurate data acquisition. The ability to handle both voltage inputs in the range of – 10 to 10V and current inputs from 4 – 20mA makes it adaptable to various industrial applications, providing the flexibility needed to interface with different types of sensors. This not only enhances the precision of industrial processes but also contributes to the overall stability and efficiency of the control system.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | IC697ALG440 |

| Manufacturer | General Electric (GE) |

| Product Type | Analog Input Module |

| Series | 90 – 30 Series |

| Input Quantity | 16 |

| Input Type | Individually configurable current or voltage differential inputs |

| Voltage Input Range | – 10 to 10V |

| Current Input Range | 4 – 20mA |

| Resolution | 16 – bit |

| Update Rate | 2.4 ms |

| Calibration | Factory – set at 10 volts ± 2 mV |

| Accuracy | ± 0.07% of full scale, ± 0.1% of value |

| Power Requirement | 0.4 amps (2 watts) at +5 volts |

| Dimensions | 4 cm x 21.8 cm x 29.2 cm |

| Weight | Approximately 0.61 kilograms |

IC697ALG440

Main Features and Advantages

High – Precision Data Acquisition

The GE IC697ALG440 offers 16 – bit resolution, enabling it to capture analog signals with a high degree of accuracy. This level of precision is essential in industrial applications where even small variations in sensor readings can impact the quality of the product or the efficiency of the process. Whether it’s a chemical plant monitoring the concentration of reactants or a manufacturing facility controlling the speed of machinery, the accurate data provided by the IC697ALG440 helps in making informed control decisions.

Versatile Input Configuration

With 16 inputs that can be individually configured for either current or voltage signals, the module provides unmatched flexibility. This means that in a single installation, it can interface with a diverse range of sensors. For example, in a power generation plant, it can simultaneously connect to voltage – based sensors monitoring grid voltage and current – based sensors measuring the load on generators. This adaptability reduces the need for multiple specialized modules, simplifying the overall system design and reducing costs.

Fast Update Rate

Featuring an update rate of 2.4 ms, the IC697ALG440 can quickly respond to changes in analog signals. In dynamic industrial processes, such as those in high – speed manufacturing lines or real – time environmental monitoring systems, this fast update rate ensures that the control system has the most current data available. It allows for rapid adjustments to be made, preventing potential issues and maintaining optimal operation.

Application Field

Manufacturing Industry

In manufacturing plants, the GE IC697ALG440 is extensively used to monitor and control production processes. It can interface with sensors on production machinery to measure parameters like temperature, vibration, and pressure. For instance, in an automotive manufacturing plant, it can be used to monitor the temperature of metal parts during the stamping and welding processes. By accurately measuring these parameters, the module helps in ensuring product quality and preventing equipment failures due to overheating or excessive stress.

Power Generation

Power plants, whether they are coal – fired, gas – fired, or hydroelectric, rely on the IC697ALG440 for precise monitoring of their operations. It can measure the voltage and current in power generation and distribution systems. In a wind farm, for example, the module can connect to sensors on wind turbines to monitor the electrical output and the performance of the turbines’ mechanical components. This data is then used to optimize power generation, ensure grid stability, and predict maintenance needs.

Process Industries

Industries such as chemical, pharmaceutical, and food and beverage use the GE IC697ALG440 to control their production processes. In a chemical plant, it can measure the flow rate, temperature, and pressure of chemical reactions. This information is crucial for maintaining the correct reaction conditions, ensuring product consistency, and preventing safety hazards. In a food and beverage factory, the module can be used to monitor the filling levels of containers or the temperature during the cooking and packaging processes, ensuring product quality and safety.

IC697ALG440 IC697ALG440 IC697ALG440

Related Products

- GE IC693ALG220: This is another analog input module from GE, but it may have different input configurations or performance characteristics compared to the IC697ALG440. It could be part of a different GE product series and might be more suitable for applications with lower – precision requirements or different signal ranges.

- GE Series 90 – 30 Digital Input Modules: These modules, unlike the IC697ALG440, are designed to handle digital signals. They can be used in combination with the IC697ALG440 in a comprehensive industrial control system, where both analog and digital data need to be processed and integrated.

- GE PLC Processors Compatible with IC697ALG440: These processors are specifically designed to work with modules like the IC697ALG440. They can process the analog data received from the module and execute control algorithms based on that data. Different models may offer varying levels of processing power and memory, allowing users to choose the one that best suits their application requirements.

- GE Analog Signal Conditioners: These devices can be used in conjunction with the IC697ALG440 to further condition analog signals. They can filter out noise, amplify weak signals, or convert signals to a more suitable format before they are fed into the module, enhancing the overall performance of the analog input system.

- GE IC697ALG441 (if exists): This could potentially be an upgraded or variant version of the IC697ALG440. It might offer additional features such as more inputs, higher accuracy, or improved communication capabilities, catering to more complex industrial applications.

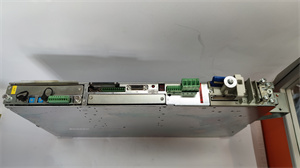

Installation and Maintenance

Pre – installation preparation: Before installing the GE IC697ALG440, ensure that the power to the entire control system is turned off to avoid electrical hazards. Check the compatibility of the module with the existing GE Series 90 – 30 system, including the type of PLC or other control devices it will be connected to. Inspect the module for any visible signs of damage during transit. Mount the module in the appropriate slot on the backplane of the control system according to the provided installation manual. Connect the analog sensors to the module’s input terminals, making sure to use the correct wiring for voltage or current signals. Pay attention to proper grounding to minimize electrical interference.

Maintenance recommendations: Regularly check the IC697ALG440 for any signs of overheating, such as discolored components or an abnormal smell. Clean the module periodically to remove dust and debris, which can affect its performance. Monitor the input signals using appropriate measuring equipment to ensure they are within the expected range. If there are any signal anomalies, check the connections, calibration, and configuration of the module. In case of a malfunction, refer to the GE – provided troubleshooting guide or contact GE’s technical support for assistance. Replace any damaged components with genuine GE parts to maintain the integrity and performance of the module.

Maintenance recommendations: Regularly check the IC697ALG440 for any signs of overheating, such as discolored components or an abnormal smell. Clean the module periodically to remove dust and debris, which can affect its performance. Monitor the input signals using appropriate measuring equipment to ensure they are within the expected range. If there are any signal anomalies, check the connections, calibration, and configuration of the module. In case of a malfunction, refer to the GE – provided troubleshooting guide or contact GE’s technical support for assistance. Replace any damaged components with genuine GE parts to maintain the integrity and performance of the module.

Product Guarantee

GE stands firmly behind the quality of the GE IC697ALG440 analog input module. The product typically comes with a comprehensive warranty, the duration of which is clearly specified in the product documentation. During this warranty period, if there are any manufacturing defects, GE will, at its discretion, repair or replace the module free of charge. GE’s global network of technical support teams is available around the clock. Whether it’s providing guidance during installation, helping with configuration, or troubleshooting operational problems, GE’s experts are committed to ensuring the optimal performance of the IC697ALG440. With strict quality control measures implemented throughout the production process, GE demonstrates its confidence in the reliability of this module, reflecting its long – standing dedication to customer satisfaction in the industrial automation market.