Description

Product Overview

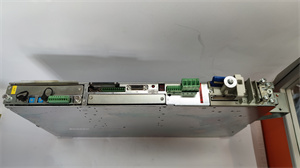

The GE EX2100 is an advanced excitation control system, serving as a cornerstone in power generation and industrial applications. As part of GE’s innovative lineup, the GE EX2100 is designed to regulate the field excitation current of generators precisely. This is crucial for maintaining stable generator AC terminal voltage and controlling reactive volt – amperes. It is a full – static excitation system, making it suitable for new installations as well as retrofitting existing steam, gas, and hydro turbines.

The GE EX2100 features a modular and flexible design. It consists of multiple controllers, power bridges, a protection module, and transformers. This architecture allows for seamless integration with other critical systems such as turbine controls, static starters, distributed control systems, and human – machine interfaces. By eliminating the need for third – party interfaces, it streamlines the overall control infrastructure, enhancing system reliability and performance. In essence, the GE EX2100 plays a pivotal role in optimizing power generation processes, ensuring efficient and stable electricity production.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | EX2100 |

| Manufacturer | General Electric |

| Product Type | Excitation Control System |

| Input Voltage | 100 – 240 VAC |

| Frequency | 50/60 Hz |

| Control Modes | Manual, Automatic, PID |

| Communication Protocols | Modbus, Profibus, Ethernet |

| Operating Temperature | -10 to 50 °C |

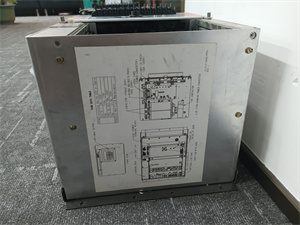

| Dimensions | [Not provided in source data, consult product manual] |

| Weight | [Not provided in source data, consult product manual] |

| Output Frequency | 50 kHz |

| Power Source Options | Potential, compound, or auxiliary source |

| System Redundancy Levels | Multiple levels available based on user needs |

GE EX2100

Main Features and Advantages

Precise Voltage Regulation

The GE EX2100 offers exceptional voltage regulation capabilities. By continuously monitoring the generator’s output voltage, it dynamically adjusts the field current. This ensures that the output voltage remains stable, even during peak load periods or when there are sudden changes in electricity demand. As a result, it provides a consistent and high – quality power supply, which is crucial for protecting electrical equipment and maintaining grid stability.

Flexible Modular Design

With its modular design, the GE EX2100 can be configured in various ways to meet different operational requirements. Users can choose from multiple levels of system redundancy, depending on the criticality of their applications. It supports different power input sources, such as potential, compound, or auxiliary sources, and offers configurations like single or multiple bridges, warm backup bridges, and simplex or redundant controls. This flexibility makes it adaptable to a wide range of power generation setups.

Seamless Integration

This excitation control system is designed for seamless integration with other systems. It can communicate with turbine controls, static starters, distributed control systems, and human – machine interfaces without the need for additional interfaces. This integration allows for better coordination between different components of a power plant, enabling operators to have a more comprehensive view and control over the entire system. It also simplifies maintenance and troubleshooting, as all components work together harmoniously.

Advanced Protection Features

The GE EX2100 is equipped with advanced protection features. It can detect abnormal conditions such as overloads, short circuits, or excessive heat. When such conditions are detected, the system automatically takes action to mitigate potential damage. This helps prevent equipment failures and minimizes unplanned downtime, ultimately saving costs for power plant operators.

Application Field

Power Generation Plants

In traditional power generation plants, whether they are coal – fired, gas – fired, or nuclear, the GE EX2100 is used to regulate the excitation of generators. It ensures stable power output, which is essential for maintaining grid frequency and voltage stability. For example, in a gas – fired power plant, it precisely controls the generator’s excitation to match the power demand, optimizing fuel consumption and reducing emissions.

Renewable Energy Installations

For renewable energy sources like wind and solar farms, the GE EX2100 also plays a crucial role. In wind turbines, it helps in stabilizing the power output, which can be intermittent due to wind speed variations. In solar power plants, it manages the excitation of generators in solar – thermal power generation systems, ensuring efficient conversion of solar energy into electricity.

Industrial Plants

Industrial plants often have their own power generation systems or use large – scale motors. The GE EX2100 is used to control the excitation of these motors and generators. In a steel manufacturing plant, for instance, it can regulate the generators that power the electric arc furnaces, ensuring a stable power supply for the high – energy – consuming manufacturing processes.

Marine and Offshore Applications

On ships and offshore platforms, reliable power generation is essential. The GE EX2100 is used to control the excitation of generators in these environments. It can withstand the harsh conditions of the marine environment, such as high humidity and salt – air corrosion, while maintaining stable power output for the operation of various equipment on board.

GE EX2100

Related Products

- GE DS2020DACAG1: A power supply module and AC – to – DC converter for the GE EX2100 excitation controller. It provides the necessary power for the controller to function properly within the excitation control system.

- GE IS200ATBAG1B: An application input/output terminal board in the GE EX2100 series. It interfaces with various sensors and actuators, allowing the GE EX2100 to receive input signals and send control signals to other components in the system.

- GE IS200BICLH1ADC: A bridge interface card in the GE EX2100 series. It plays a role in facilitating communication and signal transfer between different parts of the excitation control system, specifically related to the power bridges.

- GE IS200BPIAG1ADB: A bridge personality interface assembly in the GE EX2100 excitation control series. It likely customizes the functionality of the power bridges in the GE EX2100 system according to specific application requirements.

- GE IS200DSPXH1A: A digital signal processor controller that serves as the main controller for bridge regulator functions in the GE EX2100 series. It processes signals and controls the operation of the power bridges to ensure accurate excitation control.

Installation and Maintenance

Pre – installation preparation: Before installing the GE EX2100, ensure that the installation area is clean, dry, and free from excessive vibrations. Verify that the power supply meets the input voltage and frequency requirements of the system. Check all connection cables and connectors for any signs of damage. Familiarize yourself with the system’s wiring diagram and installation manual. Make sure to turn off all power sources related to the generator and associated systems to avoid electrical hazards during installation.

Maintenance recommendations: Regularly inspect the GE EX2100 for any visible signs of wear, such as loose connections or damaged components. Clean the system periodically to remove dust and debris, which can affect its performance. Monitor the operating temperature of the system, as overheating can lead to component failures. Check the communication protocols and ensure that the system is communicating effectively with other connected components. Periodically test the protection features of the GE EX2100 to ensure they are functioning correctly. If any issues are detected, refer to the product manual or contact GE’s technical support for assistance.

Product Guarantee

General Electric stands firmly behind the quality of the GE EX2100. The product comes with a comprehensive quality assurance program. GE guarantees that the GE EX2100 is free from manufacturing defects for a specified period. In case of any defects during this warranty period, GE will provide repair or replacement services at no additional cost to the customer. Their global network of technical support teams is available to offer prompt assistance for installation guidance, troubleshooting, and any other technical issues. This reflects GE’s confidence in the reliability and performance of the GE EX2100, ensuring customers can rely on it for their critical power generation and industrial applications.