Description

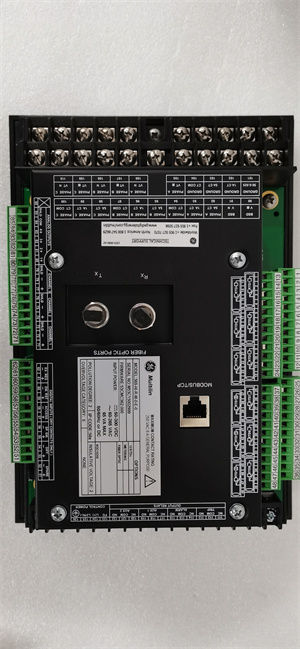

Product Overview

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 369-HI-0-M-0-0 |

| Manufacturer | GE |

| Product Type | Motor Management Relay |

| Control Power Input Range | 50 – 300 VDC / 60 – 265 VAC |

| Differential Switch Time Delay | < 200 ms |

| Dimensions | Approx: 29.6 cm (H) x 10.7 cm (W) x 20.5 cm (L) |

| Operating Range | – 40 °C (- 40 °F) to + 60 °C (140 °F) |

| Storage Range | – 40 °C (- 40 °F) to + 80 °C (176 °F) |

| Communication Ports | Non – isolated RS232 port, RS485 port |

| Optional Metering Package | Available, enables phase voltage (VT/PT) inputs, max VT ratio 240:1, includes 3 additional field – programmable analog outputs sharing a common return |

369-HI-R-M-0-E-0

Main Features and Advantages

Optional Metering Package: This relay comes with an optional metering package that significantly expands its capabilities. It allows for the enabling of phase voltage inputs, providing more detailed information about the electrical parameters of the motor. With a maximum VT ratio of 240:1 and three additional field – programmable analog outputs, it can be customized to meet specific monitoring and control needs in different industrial applications.

Local Retrieval and Connectivity: Equipped with a front LCD, it offers local retrieval capabilities, allowing operators to easily access important motor – related data on – site. Additionally, it can communicate with SCADA systems or workstations through its RS232 and RS485 ports, enabling seamless integration into larger industrial control networks for remote monitoring and control.

Adaptability: The 369 series, including the 369-HI-0-M-0-0, can “learn” individual motor parameters. This adaptability means it can adjust its protection and control functions according to the specific characteristics of each motor, providing optimized performance for different applications.

Application Field

Industrial Manufacturing: In industrial manufacturing plants, where a large number of motors are used to drive machinery such as conveyor belts, pumps, and compressors, the 369-HI-0-M-0-0 is highly applicable. It protects these motors from various faults, ensuring continuous production. For example, in a food processing factory, motors powering mixers and packaging machines can be safeguarded, preventing production halts due to motor failures.

HVAC Systems: In heating, ventilation, and air – conditioning (HVAC) systems, motors are used in fans, blowers, and compressors. The 369-HI-0-M-0-0 can monitor and protect these motors, ensuring stable operation of the HVAC system. This is crucial for maintaining a comfortable indoor environment in commercial buildings, hospitals, and offices.

Power Generation: In power generation facilities, motors are involved in processes such as fuel handling, water circulation, and turbine – related operations. The 369-HI-0-M-0-0 helps protect these motors, contributing to the reliable operation of the power plant. By preventing motor failures, it helps maintain a stable power supply to the grid.

Water and Wastewater Treatment: Motors in water and wastewater treatment plants are responsible for tasks like pumping water, aerating treatment tanks, and operating filtration systems. The 369-HI-0-M-0-0 can protect these motors, ensuring the continuous and efficient treatment of water, which is essential for public health and environmental protection.

369-HI-R-M-0-E-0

Related Products

369-HI-0-M-F-E-0: It has an optional fiber optic port, which makes it more suitable for harsh environments or applications where data transmission through fiber optic cables is necessary for better reliability and interference – free communication.

369-HI-0-M-0-0-E: Features enhanced diagnostics with an enhanced faceplate. It provides more detailed diagnostic information, which can be beneficial for complex systems where quick and accurate fault identification is crucial.

369-HI-R-M-0-P1-H-E: This model likely has additional protection or control features denoted by “P1” and “H”, making it suitable for applications with specific protection requirements, perhaps in high – risk or high – value motor – driven systems.

369-LO-0-M-F-E-0-E: Has a low control power specification (20 – 60 VDC and 20 – 48 VAC), making it suitable for applications where power consumption needs to be minimized or where the available power supply has a lower voltage range.

Installation and Maintenance

Maintenance recommendations: Regularly inspect the 369-HI-0-M-0-0 for any signs of physical damage, such as cracks or loose connections. Use the local LCD to check for any alarms or abnormal readings. Periodically test the communication ports to ensure proper connectivity with SCADA systems or workstations. If any faults are detected, refer to the troubleshooting guide in the manual. Keep the relay clean to prevent dust and debris from affecting its performance.