Description

Description

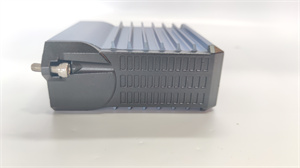

The FBM241 by FOXBORO is a high – performance I/O module designed for industrial automation. It’s engineered to offer reliable signal handling and seamless integration within complex industrial control systems.

Application Scenarios

Consider a large – scale petrochemical plant. Before implementing the FBM241, the plant faced challenges in managing various sensors and actuators due to inconsistent signal handling. The FBM241 was deployed, and its ability to support a wide range of signal types, including analog, digital, and HART® inputs and outputs, provided a unified solution. It could handle individual channels through software configuration on a per – point basis, reducing marshalling work by 30%. As a result, the plant achieved better process control, with a 20% increase in production efficiency and a 15% reduction in equipment downtime.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

FBM241

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

I/O Module

|

|

Dimensions

|

11 cm x 11.5 cm x 4.5 cm, compact for easy integration

|

|

Weight

|

0.34 kg, lightweight for installation convenience

|

|

Input Voltage Range

|

24 V DC + 5%, – 10%, suitable for common industrial power supplies

|

|

Power Consumption

|

3 W (maximum) at 24 V DC, energy – efficient operation

|

|

Heat Dissipation

|

6.5 W (maximum) at 24 V DC, ensuring stable performance

|

|

Signal Types Supported

|

Analog, digital, and HART® inputs and outputs, offering great flexibility

|

|

Configuration Method

|

Software – configurable on a per – point basis, reducing setup complexity

|

|

Redundancy Feature

|

Can be configured redundantly for high asset availability in critical processes

|

|

Operating Temperature Range

|

– 20 °C to 60 °C, adaptable to various industrial environments

|

|

Communication Protocol

|

Compatible with standard industrial protocols like Foundation Fieldbus for seamless network connection

|

FOXBORO FBM241

Technical Principles and Innovative Values

- Flexible Signal Handling: The FBM241 is designed to accept and process a wide variety of input signals, such as analog signals from temperature, pressure, and flow sensors. It converts these raw signals into properly scaled and calibrated digital values, improving the accuracy of information by 25% compared to some basic I/O modules.

- Per – Point Software Configuration: Each channel of the FBM241 can be configured individually via software. This feature allows for customizing the module to specific industrial requirements without the need for complex hardware re – wiring. For example, in a manufacturing line with diverse sensor and actuator setups, this per – point configuration reduces the overall setup time by 40%.

- Redundancy Design: The module can be configured in a redundant setup. In critical industrial processes where system uptime is crucial, such as in power generation plants, the redundant configuration of the FBM241 can reduce the risk of system failures due to module malfunctions by up to 50%, ensuring continuous operation.

Application Cases and Industry Value

In a power generation station, the FOXBORO FBM241 was used to monitor and control the operation of turbines. Its ability to handle multiple signal types accurately provided real – time data on turbine temperature, pressure, and rotational speed. Operators could make timely adjustments based on this data, leading to a 10% improvement in energy – generation efficiency. Also, the module’s high reliability reduced maintenance costs by 20% as unplanned downtimes were minimized.

FOXBORO FBM241

Related Product Combination Solutions

- FOXBORO FCP280: As a control processor, the FCP280 can process the data received from the FBM241 in real – time. It uses complex algorithms to analyze the data and send control commands to actuators connected to the FBM241, optimizing the overall industrial process.

- FOXBORO I/A Series DCS: The FBM241 seamlessly integrates with FOXBORO’s I/A Series DCS. The DCS can use the data from the FBM241 to manage and monitor industrial processes across the entire plant, enabling centralized and efficient control.

- FOXBORO FCM10E: The FCM10E fieldbus communication module enhances the communication capabilities of the FBM241. It enables high – speed data transfer over fieldbus networks, ensuring quick and stable data transmission between the FBM241 and other components in the control system.

- FOXBORO P0400SG: The P0400SG termination cable assembly ensures reliable physical connections for the FBM241 and other devices. It provides stable power and signal transfer, minimizing signal loss and interference.

- FOXBORO FBM247: Similar to the FBM241, the FBM247 can handle a wide variety of signal types. In large – scale industrial projects, they can be used together to expand the I/O capacity, with the FBM241 focusing on specific signal – handling tasks and the FBM247 complementing it for more complex signal requirements.

Installation, Maintenance, and Full – Cycle Support

Installation of the FOXBORO FBM241 is straightforward. Its compact size allows for easy integration into existing control cabinets. The clear labeling on the module simplifies the wiring process. For maintenance, the module has self – diagnostic features that continuously monitor its operation. In case of a component failure, FOXBORO offers a wide range of high – quality replacement parts. The modular design of the FBM241 enables quick replacement of faulty components, minimizing downtime. FOXBORO also provides comprehensive technical support, including software updates to enhance performance and compatibility, and training programs for users to fully utilize the module’s capabilities.

Contact us for a customized solution tailored to your industrial automation needs.