Description

Description

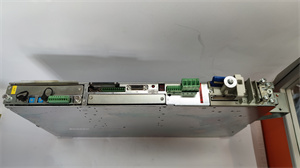

The AD207AV is an industrial control module brought to you by FOXBORO, a well – respected name in the industrial automation domain. Engineered with precision, this module is designed to offer reliable and efficient control solutions for a wide range of industrial applications.

Application Scenarios

In a large – scale oil refinery, the complex processes involve precise control of temperature, pressure, and flow rates. The refinery was grappling with inconsistent control, which led to inefficiencies and safety risks. After integrating the AD207AV module, the situation transformed. The module was used to manage the control systems of multiple distillation columns and associated pumps. It accurately processed real – time data from numerous sensors and sent out precise control signals. As a result, the refinery witnessed a 12% increase in production efficiency and a significant reduction in the number of safety – related incidents due to improved process control.

Parameter

|

Main Parameters

|

Value/Description

|

|

Product Model

|

AD207AV

|

|

Manufacturer

|

FOXBORO

|

|

Product Category

|

Industrial Control Module

|

|

Memory Configuration

|

Equipped with 16 MB SDRAM and 32 MB flash memory, providing sufficient space for data storage and quick access during operation

|

|

Input Voltage

|

Operates on a typical 24 V DC redundant voltage supply, ensuring stable operation even in case of power glitches

|

|

Fieldbus Compatibility

|

Supports up to 128 200 – series FBMS with the Fieldbus Expansion Module 100 (FEM 100) and up to 64 100 – series FBMS. It can work without a dedicated fieldbus communication module

|

|

Communication Interface

|

Connects to the grid control network via a standard 100 Mbps Ethernet optical fiber, enabling high – speed and reliable data transfer

|

|

Housing Material

|

Housed in a robust die – cast aluminum enclosure, which offers excellent protection against physical damage and electromagnetic interference

|

|

Environmental Adaptability

|

Can function in a G3 harsh environment. It has an operating temperature range of 0 to + 60 °C ( + 32 to + 140 °F), making it suitable for various industrial settings

|

|

Power Consumption

|

The maximum power consumption per non – fault – tolerant module is 8.5 W, ensuring energy – efficient operation

|

|

Configuration

|

Comes as a single – processor module. The fault – tolerant version consists of two processor modules, with an integrated interconnect fault – tolerant connector on the base plate

|

FOXBORO FBM215

Technical Principles and Innovative Values

- Innovation Point 1: Advanced Control Algorithms

The AD207AV incorporates state – of – the – art control algorithms. These algorithms are designed to adapt to changing process conditions in real – time. In a chemical reaction process with fluctuating raw material qualities, the module can automatically adjust control parameters. Compared to some traditional control modules, it can reduce process variability by up to 30%, leading to more consistent product quality.

- Innovation Point 2: High – Speed Data Processing

With its high – performance processor, the AD207AV can process data at an extremely fast rate. In a high – speed packaging line, it can analyze and control the operation of multiple packaging machines simultaneously. It can handle data flow rates that are 50% higher than some competing modules, ensuring smooth and efficient operation of the packaging process.

- Innovation Point 3: Enhanced Connectivity

The module offers wide – ranging connectivity options. It supports multiple fieldbus standards and has a high – speed Ethernet interface. In a smart factory scenario, it can easily communicate with different types of devices, such as intelligent sensors, cloud – connected servers, and other industrial controllers. This seamless connectivity enables the implementation of advanced automation strategies, such as Industry 4.0 – compliant data analytics and remote control.

FOXBORO FBM215

Application Cases and Industry Value

In a power generation plant, the FOXBORO AD207AV was deployed to control the operation of turbines. By accurately monitoring parameters like temperature, pressure, and rotational speed, it optimized the turbine’s performance. The plant reported a 10% increase in power generation efficiency and a 15% reduction in maintenance costs due to the early detection of potential equipment failures. The AD207AV‘s ability to integrate with other power – plant control systems also improved the overall grid stability.

In a food and beverage production facility, the AD207AV was used to manage the filling and capping processes. It precisely controlled the flow of liquids and the operation of capping machines. As a result, the facility achieved a 12% reduction in product waste due to over – filling or improper capping. The module’s reliability also reduced unplanned production stoppages, increasing the overall productivity of the plant.

Related Product Combination Solutions

- FOXBORO FBM200 Series: These Fieldbus Modules can be paired with the AD207AV. The FBM200 series, such as FBM201 for analog input and FBM204 for combined analog input/output, expand the input and output capabilities of the AD207AV. They work together to interface with a wide range of field devices, enabling comprehensive process control.

- FOXBORO FEM100: The Fieldbus Expansion Module 100 (FEM 100) enhances the AD207AV‘s fieldbus capabilities. It allows the AD207AV to support a larger number of 200 – series FBMS, increasing the overall system’s capacity to handle complex industrial processes.

- FOXBORO I/A Series DCS Components: The AD207AV can be integrated into the FOXBORO I/A Series Distributed Control System. It works in harmony with other components like controllers and communication modules within the I/A Series, providing a complete and reliable industrial automation solution.

- FOXBORO Communication Modules: Modules such as those supporting Profibus or other industrial communication protocols can be added to the AD207AV. These modules further enhance the AD207AV‘s communication capabilities, allowing it to connect to different industrial networks and devices more effectively.

- FOXBORO Power Supplies: Complementary FOXBORO power supplies ensure stable power for the AD207AV. These power supplies are designed to work specifically with the AD207AV, providing clean and reliable power even in the presence of electrical noise and power fluctuations in industrial environments.

Installation, Maintenance, and Full – Cycle Support

Installing the FOXBORO AD207AV is a relatively straightforward process. Its design and the comprehensive documentation provided by FOXBORO guide technicians through the steps, which include connecting power, fieldbus cables, and communication lines. The module’s compact size and standard mounting features make it suitable for installation in various control cabinets, even in space – constrained environments.

For maintenance, the AD207AV is designed for reliability. However, in case of issues, its self – diagnostic functions can quickly identify faults. FOXBORO offers a wide range of high – quality replacement parts, and their technical support team is available for on – site or remote assistance. Regular software updates are provided to enhance the module’s performance, security, and compatibility with new devices. FOXBORO’s commitment to after – sales support ensures that the AD207AV continues to operate optimally throughout its lifecycle, minimizing downtime and maximizing the return on investment for industrial users.

Contact us for a customized solution tailored to your industrial automation needs with the reliable FOXBORO AD207AV.