Description

1. Product Description

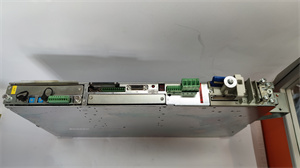

The EMERSON PR6426/000-010+CON021 is a high-precision eddy current sensor system designed for non-contact measurement of displacement, vibration, and position in rotating machinery. As part of the EPRO PR6400 series, this system combines the PR6426/000-010 eddy current sensor with the CON021 signal conditioner to deliver reliable monitoring of critical parameters such as shaft vibration, axial displacement, and eccentricity in industrial applications.

The PR6426/000-010 sensor features a 10mm measuring range with a sensitivity of 20mV/μm, enabling precise detection of minute movements in rotating components. Its robust stainless-steel housing and IP67-rated design ensure durability in harsh environments, including high temperatures (-40°C to +125°C) and electromagnetic interference (EMI) zones. The CON021 signal conditioner converts the sensor’s analog output into a standardized 4-20mA signal, facilitating seamless integration with PLCs, DCS systems, or data acquisition platforms.

2. Product Parameters

| Parameter | Details |

|---|---|

| Sensor (PR6426/000-010) | |

| Measuring Range | 10mm (axial displacement) |

| Sensitivity | 20mV/μm (±1% linearity error) |

| Frequency Response | 0 to 10kHz |

| Power Supply | -24V DC (±10%) |

| Cable Length | 5m (extendable up to 50m with compatible extension cables) |

| Signal Conditioner (CON021) | |

| Input Signal | -4V to -20V (eddy current sensor output) |

| Output Signal | 4-20mA (loop-powered) |

| Communication | RS485 (Modbus RTU) |

| Operating Temperature | -25°C to +70°C |

| Mounting | DIN rail or panel-mountable |

PR6426000-010+CON021

3. Advantages and Features

- High Accuracy: The PR6426/000-010 achieves ±1% linearity error, ensuring precise measurements for predictive maintenance in critical machinery.

- Wide Environmental Range: Operates reliably in extreme temperatures (-40°C to +125°C) and high-humidity environments, making it suitable for oil refineries, power plants, and chemical facilities.

- EMI/RFI Immunity: Shielded design and low impedance output minimize signal interference from nearby equipment, ensuring stable operation in noisy industrial settings.

- Easy Integration: The CON021’s 4-20mA output and Modbus RTU interface simplify connectivity with existing control systems, reducing integration complexity.

- Cost-Effective: Multi-sensor compatibility (eddy current, accelerometers) eliminates the need for specialized modules, lowering inventory and maintenance costs.

4. Application Areas and Application Cases

Industry Applications:

- Power Generation: Turbine shaft vibration monitoring and rotor alignment.

- Oil & Gas: Compressor axial displacement detection and bearing wear analysis.

- Manufacturing: High-speed spindle diagnostics in CNC machines.

Case Study:

In a petrochemical plant, the PR6426/000-010+CON021 was deployed to monitor a centrifugal compressor’s shaft vibration. By detecting early signs of imbalance through real-time data transmission, the system reduced unplanned downtime by 40% and extended equipment lifespan by 25%, saving over $500,000 annually in maintenance costs.

In a petrochemical plant, the PR6426/000-010+CON021 was deployed to monitor a centrifugal compressor’s shaft vibration. By detecting early signs of imbalance through real-time data transmission, the system reduced unplanned downtime by 40% and extended equipment lifespan by 25%, saving over $500,000 annually in maintenance costs.

5. Competitor Comparison

The PR6426/000-010+CON021 outperforms comparable systems in:

- Temperature Range: Supports wider operating temperatures (-40°C to +125°C) compared to competitors like Bently Nevada 3300 XL (typically -40°C to +85°C).

- Signal Conditioning: The CON021 integrates Modbus RTU, whereas many alternatives require additional modules for digital communication.

- Cost Efficiency: Offers a 30% lower total cost of ownership due to reduced calibration needs and modular design.

PR6426000-010+CON021

6. Selection Suggestions

- Compatibility Check: Ensure the PR6426/000-010 sensor’s 10mm range matches your machinery’s displacement requirements. Verify the CON021’s 4-20mA output aligns with your PLC/DCS input specifications.

- Environmental Fit: For high-temperature applications (>100°C), consider the PR6426/000-010’s extended temperature rating. Use shielded cables in EMI-prone areas.

- Redundancy: Deploy dual sensors for critical applications to enhance fault tolerance.

- Budget: While the initial cost is higher than basic sensors, the system’s long-term reliability and energy savings justify the investment.

7. Precautions

- Installation: Power down the system before connecting the PR6426/000-010 to avoid damage. Use torque wrenches to secure the sensor at the specified gap distance (typically 1.5mm).

- Calibration: Perform annual calibration using a precision displacement reference (e.g., laser interferometer) to maintain accuracy.

- Maintenance: Clean the sensor tip regularly with alcohol to remove debris. Replace worn cables immediately to prevent signal degradation.

- Software Updates: Keep the CON021 firmware updated to access new features and security patches.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.