Description

Product Overview

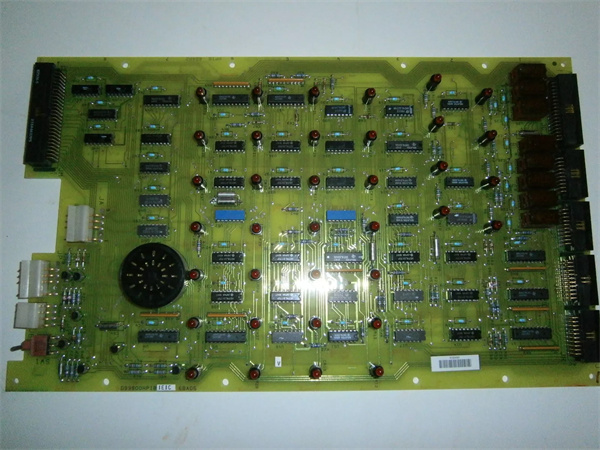

The GE DS3800DFXA1B1C is a crucial component within General Electric’s industrial automation and turbine control ecosystem. As part of the renowned Mark IV series, this printed circuit board is engineered to play a pivotal role in various industrial applications, particularly those related to turbine control systems.

The DS3800DFXA1B1C is designed to handle specific control and signal – processing functions. It interfaces with other components in the system, receiving and transmitting critical signals that are essential for the smooth operation of gas or steam turbines. By precisely regulating and managing these signals, it helps in maintaining the optimal performance of the turbine. Whether it’s adjusting the speed, controlling the fuel intake, or monitoring key parameters, the GE DS3800DFXA1B1C ensures that the turbine operates efficiently and reliably. Its position in the Mark IV series positions it as a tried – and – true solution for industrial facilities seeking high – quality, dependable control in their turbine – driven processes.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS3800DFXA1B1C |

| Manufacturer | General Electric |

| Product Type | Printed Circuit Board |

| Series | Mark IV |

| Function | Turbine control – related signal processing and regulation |

| Component Count | Multiple resistors, capacitors, and other electrical components (exact count not specified in available data) |

| Connector Type | Specific connectors for interfacing with other system components (details not fully specified) |

| Operating Temperature Range | Not provided in available data (assumed to be suitable for typical industrial environments, e.g., -20 °C to +60 °C like similar products) |

| Humidity Range | Not provided in available data (assumed to be 0% – 95% non – condensing like related industrial components) |

| Mounting Method | Likely designed for standard industrial mounting in control panels or turbine – related enclosures (specifics not given) |

| Power Requirements | Not provided in available data (expected to be compatible with common industrial power sources for such boards) |

| Communication Interface | Not provided in available data (but may support standard industrial communication protocols relevant to turbine control systems) |

DS3800HPIB

Main Features and Advantages

Reliable Performance

Built by General Electric, a trusted name in the industrial sector, the DS3800DFXA1B1C is crafted with high – quality materials and undergoes rigorous testing. This ensures that it can operate consistently in demanding industrial environments, minimizing the risk of system failures and disruptions in turbine operations.

Precise Signal Handling

The board is optimized for accurate signal processing. It can precisely interpret incoming signals from sensors and transmit control signals to actuators in the turbine system. This precision is crucial for maintaining the correct speed, power output, and other vital parameters of the turbine, leading to enhanced efficiency and reduced wear and tear on turbine components.

Compatibility within Mark IV Series

As part of the Mark IV series, the DS3800DFXA1B1C benefits from seamless compatibility with other components in the same series. This allows for easy integration into existing or new turbine control setups, simplifying the system design and reducing the complexity of installation and maintenance.

Application Field

In power generation plants, the GE DS3800DFXA1B1C is extensively used in gas and steam turbine control systems. It helps in regulating the turbine’s operation to ensure a stable and efficient power supply. For example, in a natural gas – fired power plant, the board can control the gas flow rate to the turbine based on the power demand, optimizing fuel consumption and power generation efficiency.

In industrial manufacturing facilities that use turbines for mechanical drive applications, such as in large – scale manufacturing processes or in refineries for driving pumps and compressors, the DS3800DFXA1B1C plays a key role. It ensures that the turbines operate at the required speed and torque, enabling smooth production processes.

In the aerospace industry, where turbines are used in aircraft engines and ground support equipment, the DS3800DFXA1B1C can be utilized in test rigs and auxiliary power units. It helps in monitoring and controlling the turbine’s performance during testing and operation, contributing to the safety and reliability of aerospace systems.

In industrial manufacturing facilities that use turbines for mechanical drive applications, such as in large – scale manufacturing processes or in refineries for driving pumps and compressors, the DS3800DFXA1B1C plays a key role. It ensures that the turbines operate at the required speed and torque, enabling smooth production processes.

In the aerospace industry, where turbines are used in aircraft engines and ground support equipment, the DS3800DFXA1B1C can be utilized in test rigs and auxiliary power units. It helps in monitoring and controlling the turbine’s performance during testing and operation, contributing to the safety and reliability of aerospace systems.

Related Products

- DS3800DFPF1B1C: Also a printed circuit board from GE’s Mark IV series. It likely has different specific functions but is part of the same ecosystem. While the DS3800DFXA1B1C focuses on its particular turbine control aspects, the DS3800DFPF1B1C may handle other related functions like a different type of signal processing or interface with a specific subset of components within the turbine control system.

- DS3800DMEB1B1C: A gas turbine control board. It has a more direct focus on gas turbine control compared to the DS3800DFXA1B1C. The DS3800DMEB1B1C might handle tasks such as direct control of gas – related parameters in the turbine, while the DS3800DFXA1B1C could be more involved in the overall signal – management infrastructure that supports such control functions.

- DS3800DFXB1: A regulator board in the speedtronic mark iv systems. It has some similarities in terms of being part of the Mark IV series for turbine control. However, the DS3800DFXB1 may have a more specialized role in regulating specific electrical or control parameters, while the DS3800DFXA1B1C has a broader set of functions related to overall turbine operation management.

- DS3800DGPA1A1B: A generator gas turbine circuit card. It is designed for a more specific application within the turbine – generator setup. The DS3800DGPA1A1B may be directly involved in generator – related control within the gas turbine system, while the DS3800DFXA1B1C provides more general – purpose control and signal – handling functions that support both the turbine and generator operation.

- DS3800NMEC1C1B: A motor exciter control board. It has a different focus on motor excitation control within the turbine system. The DS3800NMEC1C1B is mainly concerned with managing the excitation of motors associated with the turbine, while the DS3800DFXA1B1C addresses a wider range of turbine – control aspects beyond just motor excitation.

Installation and Maintenance

Pre – installation preparation: Before installing the GE DS3800DFXA1B1C, carefully review the installation manual provided by GE. Ensure that the installation environment meets the temperature and humidity requirements, although these are not specified in the available data, typical industrial standards should be considered. Check the power supply to ensure it is compatible with the board’s requirements. Verify that all the connectors on the DS3800DFXA1B1C and the mating components are clean and free from any debris or damage. When handling the board, use proper electrostatic discharge (ESD) protection to prevent damage to the sensitive electronic components.

Maintenance recommendations: Regularly inspect the DS3800DFXA1B1C for any signs of physical damage, such as cracks on the circuit board or loose connections. Monitor the overall performance of the turbine system that the board is a part of. If there are any abnormal behaviors in the turbine operation, it could be an indication of an issue with the DS3800DFXA1B1C or other related components. Periodically clean the board to remove any accumulated dust, as dust can affect the heat dissipation and electrical performance. If possible, perform diagnostic tests on the board at regular intervals to detect any potential issues before they lead to system failures.

Maintenance recommendations: Regularly inspect the DS3800DFXA1B1C for any signs of physical damage, such as cracks on the circuit board or loose connections. Monitor the overall performance of the turbine system that the board is a part of. If there are any abnormal behaviors in the turbine operation, it could be an indication of an issue with the DS3800DFXA1B1C or other related components. Periodically clean the board to remove any accumulated dust, as dust can affect the heat dissipation and electrical performance. If possible, perform diagnostic tests on the board at regular intervals to detect any potential issues before they lead to system failures.

Product Guarantee

General Electric stands firmly behind the quality of the GE DS3800DFXA1B1C. The product is subjected to strict quality control measures during the manufacturing process to meet the highest industry standards. GE offers a comprehensive product guarantee, which typically includes a warranty period. During this time, if the DS3800DFXA1B1C experiences any defects in materials or workmanship, GE will provide prompt repair or replacement services. Their team of experienced technicians is available to offer technical support. Whether it’s for installation guidance, troubleshooting, or advice on maintenance, customers can rely on GE’s expertise. This commitment to quality and after – sales service gives users confidence in the long – term performance and reliability of the DS3800DFXA1B1C in their industrial applications.