Description

Product Overview

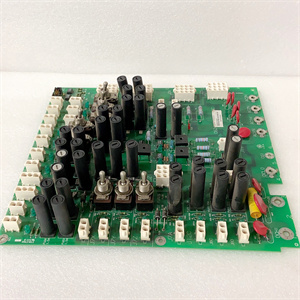

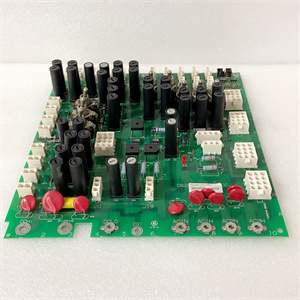

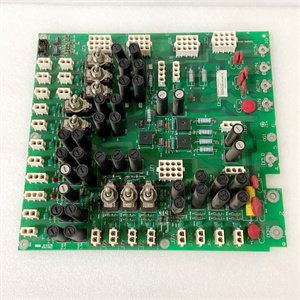

The General Electric DS200TCPDG1BEC is a power distribution board that plays a pivotal role within the Mark V series of turbine control systems. This board is designed to distribute power with precision and reliability to various components within the system, including processors, memory units, and I/O devices. In the context of industrial automation, the DS200TCPDG1BEC acts as a crucial link in ensuring the stable operation of the overall control system. It serves as the power backbone, providing the necessary electrical energy to keep all connected devices functioning optimally.

With its advanced design, the DS200TCPDG1BEC offers efficient power management, which is essential for the seamless operation of the Mark V system. Its high – quality construction and reliable performance make it a go – to choice for industries relying on turbine – related applications. Whether in a power generation plant or an industrial manufacturing setting where turbines are used, this power distribution board ensures that power is delivered consistently, contributing to the overall productivity and stability of the operations.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS200TCPDG1BEC |

| Manufacturer | General Electric |

| Product Type | Power Distribution Board |

| Voltage | 24V DC |

| Current | 20A |

| Number of Channels | 8 |

| Output Type | Relay Contact |

| Input Type | Digital |

| Dimensions | 118 mm x 105mm x 48 mm |

| Weight | 0.3 kg |

| Fuses | 36 |

| Toggle Switches | 8 |

| Signal Wire Terminals | 4 |

DS200TCPDG2BEC

Main Features and Advantages

Reliable Power Output: The DS200TCPDG1BEC is engineered with high – grade components and advanced circuit designs, guaranteeing a stable power output. This stability is crucial as it minimizes the risk of power fluctuations that could potentially disrupt the operation of connected components. In industrial environments where continuous and reliable power is essential, the board’s ability to maintain a steady power supply ensures smooth running of processes.

Redundant Design for Fault Tolerance: It features a redundant component design. In the event of a component failure, the board can continue to function through its redundant channels. This significantly enhances the system’s fault – tolerance, reducing the likelihood of system – wide failures. For example, if one of the power distribution paths fails, the redundant path can take over, ensuring uninterrupted power supply to critical components.

Built – in Self – Test Function: Equipped with a built – in self – test mechanism, the DS200TCPDG1BEC can autonomously monitor its own operational status. When an issue is detected, it promptly sends out an alarm signal. This not only allows maintenance personnel to quickly identify and address problems but also helps in reducing maintenance time and costs. Regular self – testing ensures that the board is always in a fit – for – purpose condition.

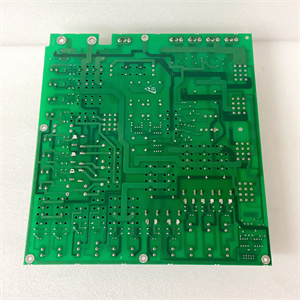

Compact and Space – Saving Design: With its compact structure, the DS200TCPDG1BEC is space – efficient. It can be easily installed in tight spaces within control cabinets, saving valuable installation space. This also simplifies the overall system layout, making it easier to integrate into existing or new Mark V control systems.

Application Field

Power Generation Plants: In power generation plants, especially those with steam turbines, the DS200TCPDG1BEC is indispensable. It provides the necessary power for the operation of steam turbines, ensuring stable power generation. By distributing power to various turbine – related components such as sensors, actuators, and control units, it helps maintain the optimal performance of the turbine, thus contributing to the overall efficiency of power production.

Auxiliary Systems in Power Plants: The board is also used in the control of auxiliary systems within power plants. This includes systems like lubrication systems, which require a stable power supply to ensure proper lubrication of turbine components, and cooling systems, where consistent power is needed to regulate the temperature of the turbine. Additionally, it powers the control systems that monitor and manage these auxiliary functions.

Other Industrial Applications: Beyond power plants, in industries such as petrochemical, metallurgy, and mechanical manufacturing, where high – reliability power distribution is crucial, the DS200TCPDG1BEC finds extensive use. In a petrochemical plant, for example, it can power the pumps and valves that are integral to the chemical processing operations. In a metallurgical plant, it may supply power to the machinery involved in metal smelting and shaping processes.

DS200TCPDG2BEC

Related Products

- DS200TCTGG1AFF: Another board within the Mark V series. It is likely related to turbine trip control functions, serving a different but complementary role compared to the power – distributing DS200TCPDG1BEC.

- IS215UCVEH2A: A component of the GE automation system. It is used in different subsystems, perhaps for data processing or communication, and has a distinct function from the DS200TCPDG1BEC power distribution board.

- VMIVME – 7807: This module is part of GE’s industrial computer systems. It is mainly used for data processing and communication, which is different from the power – distribution function of the DS200TCPDG1BEC.

- WES532 – 111: Involved in specific industrial control applications of GE. Its function and application scenario are different from those of the DS200TCPDG1BEC, but it may be used in combination within a larger industrial control system.

- IS230SRT – DH2A: A GE product that may be engaged in signal processing or other control – system – related tasks. It has no direct relation to the power – distribution function of the DS200TCPDG1BEC.

Installation and Maintenance

Pre – installation preparation: Before installing the DS200TCPDG1BEC, always ensure that the power supply to the relevant system is turned off to prevent electrical hazards. Thoroughly check the model and specifications of the board to confirm compatibility with the Mark V system requirements. Clean the installation area to eliminate any dust or debris that could potentially affect the board’s performance.

Maintenance recommendations: Regularly inspect the fuses on the DS200TCPDG1BEC. If a fuse is blown, replace it promptly following the correct procedures. Periodically check the connection of the signal wire terminals to ensure they are secure and free from looseness. Clean the surface of the board regularly to prevent dust accumulation, as this can impact heat dissipation and overall performance.

Product Guarantee

General Electric stands firmly behind the quality of the DS200TCPDG1BEC. The product undergoes strict quality inspections before leaving the factory to meet high – industry standards. In case of any manufacturing defects during the warranty period, GE offers comprehensive repair or replacement services. Their professional technical team is available to provide timely technical support. Whether it’s during installation, for operational queries, or maintenance – related issues, customers can rely on GE’s commitment to ensure the normal operation of the DS200TCPDG1BEC, instilling confidence in their investment.