Description

Product Overview

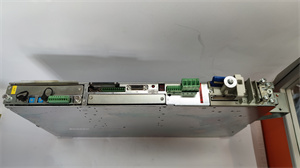

The GE DS200TBQCG1AAA is an analog input/milliamp I/O termination module, integral to the GE Speedtronic Mark V series. As a key component in turbine control systems, it plays a pivotal role in ensuring seamless operation. This module is designed to interface with external I/O, offering reliable signal termination and distribution within the control setup.

The DS200TBQCG1AAA is engineered to handle analog input and milliamp I/O signals with precision. It provides a stable connection point for various sensors and actuators, enabling the efficient transfer of data. With its compatibility within the Mark V series, it can be easily integrated into existing systems, enhancing their functionality. Whether in a power generation plant or an industrial manufacturing facility, this module helps maintain the stability and performance of the overall turbine control system. Its high – speed networked I/O capabilities support simplex, dual, and triple – redundant systems, catering to diverse industrial requirements.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

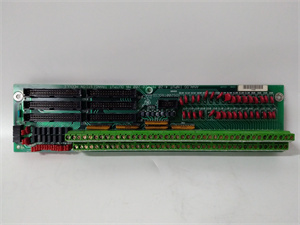

| Product Model | DS200TBQCG1AAA |

| Manufacturer | General Electric |

| Product Type | Analog Input/Milliamp I/O Termination Module |

| Series | Mark V |

| PCB Coating | Normal Coating |

| Terminal Blocks | 2 |

| Terminals per Block | 83 |

| Jumpers | 15 |

| 40 – pin Connectors | 3 |

| 34 – pin Connectors | 3 |

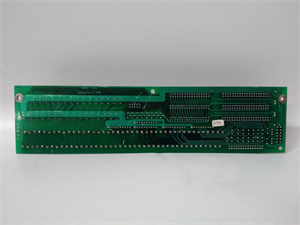

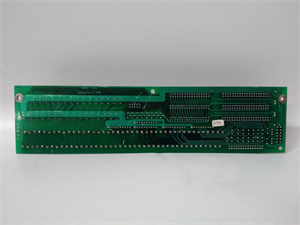

| Board Length | 11.25 inches |

| Board Height | 3 inches |

| Compatibility | Compatible with relevant components in the Mark V series |

| Function | Signal termination and distribution for analog input and milliamp I/O |

DS200TBQCG1AAA

Main Features and Advantages

Reliable signal handling: The GE DS200TBQCG1AAA is constructed with high – quality components, ensuring accurate and stable analog input and milliamp I/O signal transmission. Its design minimizes signal interference and distortion, providing reliable data for the turbine control system. This reliability is crucial for maintaining the consistent operation of turbines, preventing unexpected shutdowns and ensuring optimal performance.

Flexible connectivity: Equipped with multiple types of connectors and terminals, the module can interface with a wide range of external devices and sensors. This flexibility allows for seamless integration into different system architectures, adapting to the specific requirements of various industrial applications. Whether it’s connecting to standard sensors or more specialized equipment, the DS200TBQCG1AAA can handle the task with ease.

High – speed networked I/O: It supports high – speed networked I/O, which enables rapid communication between different components in the control system. This feature is essential for real – time monitoring and control of turbines. With quick data transfer, the system can respond promptly to any changes in turbine operation, enhancing overall system efficiency and responsiveness.

Compatibility and integration: As part of the GE Speedtronic Mark V series, the DS200TBQCG1AAA is highly compatible with other components in the series. This compatibility simplifies system integration, making it easier to upgrade or expand existing control systems. It can work in harmony with other modules, reducing the complexity of system design and implementation.

Flexible connectivity: Equipped with multiple types of connectors and terminals, the module can interface with a wide range of external devices and sensors. This flexibility allows for seamless integration into different system architectures, adapting to the specific requirements of various industrial applications. Whether it’s connecting to standard sensors or more specialized equipment, the DS200TBQCG1AAA can handle the task with ease.

High – speed networked I/O: It supports high – speed networked I/O, which enables rapid communication between different components in the control system. This feature is essential for real – time monitoring and control of turbines. With quick data transfer, the system can respond promptly to any changes in turbine operation, enhancing overall system efficiency and responsiveness.

Compatibility and integration: As part of the GE Speedtronic Mark V series, the DS200TBQCG1AAA is highly compatible with other components in the series. This compatibility simplifies system integration, making it easier to upgrade or expand existing control systems. It can work in harmony with other modules, reducing the complexity of system design and implementation.

Application Field

Power generation: In power plants, the GE DS200TBQCG1AAA is extensively used in gas, steam, and wind turbine control systems. It monitors and controls various parameters such as temperature, pressure, and rotational speed. By accurately processing analog input signals from sensors, it helps in optimizing the power generation process, ensuring stable electricity production and efficient energy conversion.

Industrial manufacturing: In industrial manufacturing facilities, the module is used in processes that require precise control of analog input and milliamp I/O signals. For example, in chemical plants, it can monitor and control the flow and pressure of fluids. In metal processing plants, it may be used to control the operation of machinery based on analog sensor data, improving product quality and production efficiency.

Large – scale industrial automation: In large – scale industrial automation systems, the DS200TBQCG1AAA serves as an important interface for connecting different subsystems. It enables seamless communication between sensors, actuators, and controllers, facilitating the integration and coordinated operation of various components. This is crucial for maintaining the smooth running of complex industrial processes, such as those in automotive manufacturing plants or large – scale logistics centers.

Industrial manufacturing: In industrial manufacturing facilities, the module is used in processes that require precise control of analog input and milliamp I/O signals. For example, in chemical plants, it can monitor and control the flow and pressure of fluids. In metal processing plants, it may be used to control the operation of machinery based on analog sensor data, improving product quality and production efficiency.

Large – scale industrial automation: In large – scale industrial automation systems, the DS200TBQCG1AAA serves as an important interface for connecting different subsystems. It enables seamless communication between sensors, actuators, and controllers, facilitating the integration and coordinated operation of various components. This is crucial for maintaining the smooth running of complex industrial processes, such as those in automotive manufacturing plants or large – scale logistics centers.

DS200TBQCG1AAA

Related Products

DS200TBQCG1: The parent printed circuit board of DS200TBQCG1AAA without the A – rated functional product revision. It has similar basic functions but may lack some of the specific enhancements or modifications present in the DS200TBQCG1AAA.

DS200TBQCH1: Another termination module in the Mark V series. It might have different signal input and output configurations, perhaps designed for specific applications or types of signals within the turbine control system.

DS200TBQCL1: This module could be optimized for different requirements, such as better noise – immunity or higher – precision signal handling, compared to the DS200TBQCG1AAA.

DS200TBQCM1: It may offer enhanced capabilities in terms of signal processing speed or communication protocols, making it suitable for more complex or high – performance turbine control scenarios.

DS200TBQCP1: Likely to have different pin – out configurations or connection requirements, providing alternative options for system integration depending on the specific needs of the industrial setup.

DS200TBQCH1: Another termination module in the Mark V series. It might have different signal input and output configurations, perhaps designed for specific applications or types of signals within the turbine control system.

DS200TBQCL1: This module could be optimized for different requirements, such as better noise – immunity or higher – precision signal handling, compared to the DS200TBQCG1AAA.

DS200TBQCM1: It may offer enhanced capabilities in terms of signal processing speed or communication protocols, making it suitable for more complex or high – performance turbine control scenarios.

DS200TBQCP1: Likely to have different pin – out configurations or connection requirements, providing alternative options for system integration depending on the specific needs of the industrial setup.

Installation and Maintenance

Pre – installation preparation: Before installing the GE DS200TBQCG1AAA, ensure the power to the relevant equipment is switched off and any residual electricity is discharged. Thoroughly inspect the installation environment to confirm it is clean, dry, and free from electromagnetic interference. Carefully read the installation manual and gather all the necessary tools. Check the integrity of the module for any visible signs of damage.

Maintenance recommendations: Regularly examine the connection status of the DS200TBQCG1AAA to make sure connectors and terminals are firmly attached. Periodically clean the module’s surface to prevent dust and dirt from accumulating, as these can affect its performance. In case of any faults, refer to the troubleshooting guide provided in the manual. It is advisable to have trained and experienced technicians carry out maintenance and repair work to guarantee the proper functioning of the module.

Maintenance recommendations: Regularly examine the connection status of the DS200TBQCG1AAA to make sure connectors and terminals are firmly attached. Periodically clean the module’s surface to prevent dust and dirt from accumulating, as these can affect its performance. In case of any faults, refer to the troubleshooting guide provided in the manual. It is advisable to have trained and experienced technicians carry out maintenance and repair work to guarantee the proper functioning of the module.

Product Guarantee

GE stands firmly behind the quality of the GE DS200TBQCG1AAA. The company offers a comprehensive quality assurance program. Under normal usage conditions, if any quality issues arise within the specified warranty period, GE provides prompt after – sales service. Their team of technical experts is available to offer detailed guidance on installation, troubleshooting, and, if required, arrange for the timely repair or replacement of the DS200TBQCG1AAA. This reflects GE’s confidence in the product’s durability and reliability, ensuring that industrial users can rely on it for long – term, trouble – free operation in their control systems.