Description

Product Overview

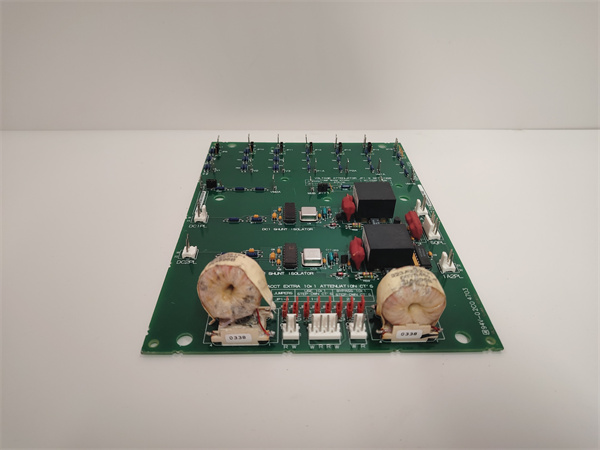

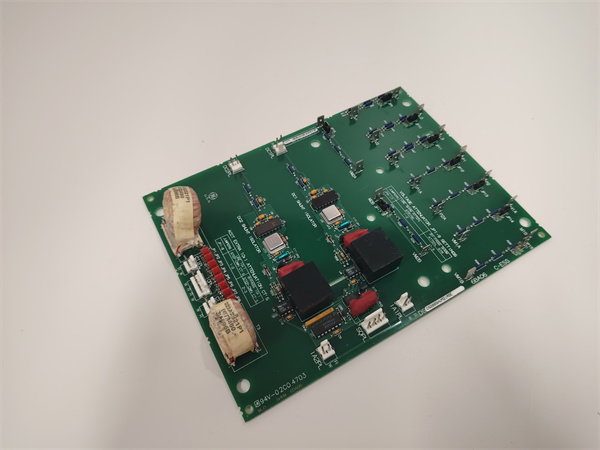

The GE DS200SHVMG1AFE is a high – voltage M – frame interface board, designed by General Electric as a critical part of the Mark V series. This series is well – known for its applications in the control and management systems of automatic drive components for wind, steam, and gas turbines. The DS200SHVMG1AFE plays a vital role in enhancing the reliability and efficiency of GE’s Mark V turbine control systems.

When installed, the DS200SHVMG1AFE provides an interface medium. It enables communication between the M – frame driver’s SCR bridge, power board (either DCFB or SDCI), and power connection card (PCCA). This board is responsible for signal conversion and certain electrical functions. For example, it can convert shunt signals ranging from – 500mV to 500mV into differential frequency outputs within the range of 0 to 500 kHz, thanks to the voltage – controlled oscillator (VCO) circuit on the board. This conversion is crucial for accurate signal transmission and system operation in industrial turbine setups.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS200SHVMG1AFE |

| Manufacturer | GE |

| Product Type | High – Voltage M – Frame Interface Board |

| Series | Mark V |

| Interface Board Dimensions (LxWxH) | 8.2 cm x 12.2 cm x 6 cm |

| Weight | 0.36 kg |

| Number of Channels | 12 |

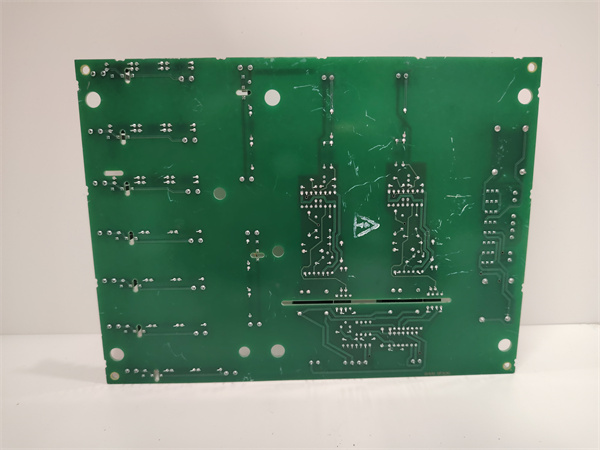

| Material | High – grade aluminum alloy for enhanced durability and heat dissipation |

| Protection Features | Integrated circuits and protective coatings to safeguard against static electricity and overvoltages |

| Connectivity | Compatibility with GE’s Mark V series, ensuring compatibility and interchangeability with other modules |

| Jumper Configuration | 17 configurable jumpers for precise customization |

| Signal Conversion | Converts – 500mV to 500mV shunt signals to 0 – 500 kHz differential frequency outputs |

DS200SHVMG1AGE

Main Features and Advantages

Reliable Signal Conversion

The GE DS200SHVMG1AFE is proficient in converting shunt signals to differential frequency outputs. The voltage – controlled oscillator (VCO) circuit on the board accurately transforms signals from – 500mV to 500mV into frequencies between 0 and 500 kHz. This precise conversion ensures that the signals are in the appropriate format for the connected components in the turbine control system, such as the power board and power connection card, promoting seamless communication and operation.

Sturdy and Durable Design

Constructed with a high – grade aluminum alloy, this interface board offers excellent durability. The material not only withstands the mechanical stresses of industrial environments but also aids in efficient heat dissipation. Additionally, the integrated circuits and protective coatings shield the board from static electricity and overvoltages. These protective features are crucial in maintaining the integrity of the board and its components, thus extending its lifespan and reducing the risk of malfunctions in the often harsh conditions of industrial turbine operations.

Customizable Configuration

Featuring 17 configurable jumpers, the DS200SHVMG1AFE allows users to fine – tune its performance according to specific requirements. This high level of customization ensures optimal system integration. Whether it’s adjusting the signal thresholds, frequency settings, or other parameters related to the interface functions, the jumpers provide the flexibility to adapt the board to different setups within the Mark V turbine control systems.

DS200SHVMG1AGE

Application Field

The GE DS200SHVMG1AFE finds extensive use in the energy sector, particularly in power generation plants. In gas turbine – based power generation, it plays a key role in facilitating communication between different control components. By ensuring accurate signal conversion and transmission, it helps in maintaining the stable operation of the gas turbine, optimizing power generation efficiency.

In the wind energy industry, where wind turbines need precise control systems, the DS200SHVMG1AFE is also an essential component. It enables seamless interaction between the various electrical and control elements within the wind turbine’s control system. This ensures that the wind turbine can operate efficiently under different wind conditions, adjusting its speed and power output as required.

Moreover, in steam turbine – driven power plants, the board is used to interface between the SCR bridge, power boards, and power connection cards in the turbine control system. It helps in regulating the steam turbine’s operation, ensuring smooth power generation and contributing to the overall reliability of the power plant’s operations.

Related Products

- GE DS200SHVMG1AGE: Similar to the DS200SHVMG1AFE, it is also a high – voltage M – frame interface board in the Mark V series. However, it may have some differences in terms of specific functionality or hardware revisions. For example, it could have a different version of the VCO circuit or slight variations in the jumper configuration for different application requirements.

- GE DS200DCFBG1A: This is a power supply board. It works in tandem with the DS200SHVMG1AFE in the Mark V turbine control system. The DS200SHVMG1AFE provides the necessary signal conversion, and the DS200DCFBG1A supplies the appropriate power levels to drive the various components in the system, ensuring coordinated operation.

- GE Mark V Series CPUs: These central processing units are the brains of the Mark V system. The DS200SHVMG1AFE interfaces with the CPU, sending and receiving signals related to the control of the turbine. The CPU manages the overall control logic, while the DS200SHVMG1AFE focuses on the high – voltage interface and signal conversion aspects.

- GE PCCA (Power Connect Card): As an important part of the system, the PCCA is connected to the DS200SHVMG1AFE. The DS200SHVMG1AFE sends the converted differential frequency signals to the PCCA, which then further processes and distributes these signals to other relevant components in the turbine control setup.

- GE Speedtronic Logic Inverter (IC3600LIVD1): Although it has a different function from the DS200SHVMG1AFE, it is part of the GE Speedtronic system. In some cases, the logic inverter may work in combination with the DS200SHVMG1AFE to control the overall logic and signal flow in the turbine control system, especially when dealing with complex control algorithms and signal processing requirements.

Installation and Maintenance

Pre – installation preparation: Before installing the GE DS200SHVMG1AFE, make sure the power to the entire Mark V turbine control system is switched off to avoid electrical hazards. Thoroughly inspect the board for any visible damage, such as bent pins or cracks on the casing. Familiarize yourself with the installation location and the connections it will make with other components like the SCR bridge, power board, and power connection card. Ensure that the installation area meets the environmental requirements in terms of temperature, humidity, and dust levels. When installing, carefully follow the wiring diagram provided in the product manual to correctly connect the board to the relevant components.

Maintenance recommendations: Regularly monitor the DS200SHVMG1AFE for any signs of abnormal operation. Check the status of the signals it converts and transmits. Clean the board periodically to remove dust and debris, especially from the connectors, as these can affect signal quality. If any issues arise, such as incorrect signal conversion or communication failures, refer to the detailed troubleshooting guide in the product manual. It is also advisable to keep the board’s firmware updated, if possible, to benefit from the latest performance improvements and bug fixes. In case of complex problems, contact GE’s technical support team for assistance.

Product Guarantee

GE stands firmly behind the quality of the GE DS200SHVMG1AFE. The board is manufactured under strict quality – control measures to meet high – standard industrial requirements. GE offers a standard warranty, during which, if the product develops any defects in materials or workmanship, they will provide free repair or replacement services. Their technical support team is available around the clock to offer remote diagnostic services and, if necessary, on – site assistance. This reflects GE’s confidence in the reliability of the DS200SHVMG1AFE and their commitment to ensuring customer satisfaction in industrial turbine control applications.