Description

Product Overview

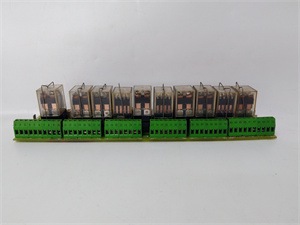

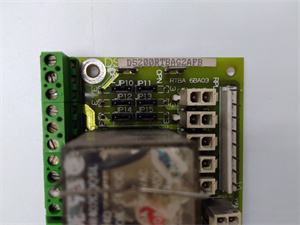

The GE DS200RTBAG2AFB is a highly specialized relay terminal board designed as an integral part of the GE Mark V Speedtronic system. This printed circuit board serves a crucial role in industrial control applications, particularly those related to turbine control. It acts as an interface between control signals and the actuators or other components in the system, enabling precise control over various operations.

In the context of the Mark V Speedtronic platform, the DS200RTBAG2AFB provides additional relay capabilities. It is engineered to handle the switching and distribution of electrical signals, ensuring that the control commands are accurately translated into actions in the connected devices. With its well – defined functionality, this board is a key element in maintaining the reliability and efficiency of industrial processes where turbine control is involved, whether it’s in power generation plants, oil and gas facilities, or other industrial settings.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS200RTBAG2AFB |

| Manufacturer | GE |

| Product Type | Relay Terminal Board |

| Rated Operating Voltage | 220 V (varies depending on application requirements) |

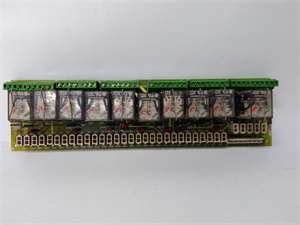

| Number of Relays | 10 |

| Relay Types | DPDT (7 units, with 2 C – type contacts each, 10A per contact) and 4PDT (3 units, with 4 C – type contacts each, 1A per contact) |

| Input Voltage Protection | Protected by 130 VAC metal – oxide varistors (MOV) |

| Relay Coil Voltage | 110 VDC |

| Dimensions | [Insert specific dimensions if available, e.g., length x width x height in cm] |

| Weight | [Insert weight value if available, e.g., in kg] |

| Operating Temperature Range | [Typical industrial temperature range, e.g., – 20 °C to + 60 °C] |

| Communication Protocols | Not directly applicable as a relay terminal board, but interfaces with systems that may use various industrial communication protocols |

| Mounting Type | [Describe the type of mounting, e.g., panel – mount or rack – mount] |

DS200RTBAG2AFB

Main Features and Advantages

Multiple Relay Configuration

The GE DS200RTBAG2AFB comes equipped with a total of ten relays, consisting of two types: DPDT and 4PDT. The seven DPDT relays offer two C – type contacts each, capable of handling up to 10A per contact. This is beneficial for applications that require higher current – handling capabilities, such as power – intensive industrial processes. The three 4PDT relays, on the other hand, have four C – type contacts each with a 1A rating per contact, providing flexibility for applications with lower current requirements. This diverse relay configuration allows the board to be used in a wide range of industrial scenarios.

Voltage Protection

Featuring 130 VAC metal – oxide varistors (MOV), the board offers robust protection against voltage surges. These MOVs safeguard the relays and other components on the board from potential damage caused by abnormal voltage spikes in the electrical system. This protection mechanism is crucial in industrial environments where electrical disturbances are common, ensuring the long – term reliability and stability of the DS200RTBAG2AFB and the overall control system.

Easy Relay Replacement

In the event of a relay failure, users can easily remove and replace all ten relays on the DS200RTBAG2AFB. This simplicity in replacement not only reduces downtime but also makes maintenance more cost – effective. There’s no need for complex procedures or specialized tools, enabling quick restoration of the board’s full functionality.

Compatibility with GE Mark V Systems

As a part of the GE Mark V Speedtronic system, the DS200RTBAG2AFB is designed for seamless integration. It works in harmony with other components within the Mark V platform, ensuring smooth communication and coordinated operation. This compatibility simplifies system design and implementation, making it easier for engineers to build reliable industrial control systems.

DS200RTBAG2AFB

Application Field

In power generation plants, the GE DS200RTBAG2AFB plays a significant role in controlling turbines. It can be used to manage the opening and closing of valves that regulate the flow of steam or fuel to the turbine. By accurately switching the relays based on control signals from the turbine control system, it helps maintain the optimal speed and power output of the turbine, ensuring efficient power generation.

Oil and gas facilities also rely on the DS200RTBAG2AFB for various control applications. For example, in oil refineries, it can control the operation of pumps and compressors. The relays on the board can be used to start or stop these devices based on process requirements, such as maintaining a certain pressure or flow rate in the pipelines. In gas processing plants, it can be used to control the safety – critical equipment, ensuring the safe and reliable operation of the facility.

In industrial manufacturing plants that use turbines for power or process control, the GE DS200RTBAG2AFB is used to interface between the control system and the equipment. It can control the speed of conveyor belts, the operation of robotic arms, or other machinery that is powered or controlled by the turbine – based system. This allows for precise control over the manufacturing process, improving product quality and production efficiency.

Related Products

- DS200RTBAG1A: Another relay terminal board in the GE Mark V series. It is similar to the DS200RTBAG2AFB, but may have differences in the number or type of relays, or in some other technical specifications. For example, it could have a different relay contact rating, making it more suitable for applications with different current requirements.

- IS420UCSBS1A: A safety – oriented controller module by GE. While the DS200RTBAG2AFB focuses on relay – based signal switching, the IS420UCSBS1A is more about overall safety control in industrial systems. In a complex industrial setup, the DS200RTBAG2AFB could receive control signals from the IS420UCSBS1A and then actuate the relevant relays to perform specific tasks.

- IC697MDL652: A discrete input module from GE. It can be used in combination with the DS200RTBAG2AFB in an industrial control system. The IC697MDL652 can capture digital input signals from sensors or switches in the field, and these signals can then be processed by the main control system. The control system can then send commands to the DS200RTBAG2AFB to actuate the relays based on the input signals.

- DS200TCQBG1A: An RST – extended analog I/O board in the GE Mark V series. It has a different function compared to the DS200RTBAG2AFB. While the DS200RTBAG2AFB is for relay – based signal switching, the DS200TCQBG1A is more focused on handling analog input and output signals. However, in a comprehensive industrial control system, both boards can be used together to manage different types of signals and control various aspects of the process.

- GE Multilin 469 – P5 – HI – A20 – H: A motor relay by GE. It is designed specifically for motor control applications. In an industrial setting, the DS200RTBAG2AFB could be used to control the power supply to motors, while the GE Multilin 469 – P5 – HI – A20 – H provides protection and control functions for the motors themselves, such as over – current protection and speed control.

Installation and Maintenance

Pre – installation preparation: Before installing the GE DS200RTBAG2AFB, ensure that all power sources in the system are turned off to prevent electrical shock. Check the physical condition of the board for any signs of damage during transit. Verify that the rated voltage of the board (220 V in most cases) matches the voltage of the electrical system where it will be installed. Also, make sure the mounting location has enough space to accommodate the board and that the mounting method (such as panel – mount or rack – mount) is appropriate.

Maintenance recommendations: Regularly inspect the DS200RTBAG2AFB for any visible signs of overheating, such as discoloration of the board or relays. Check the connections of the wires to the board to ensure they are secure and free from corrosion. Monitor the operation of the relays by periodically checking if they are switching correctly based on the control signals. If any relay fails, replace it promptly using the easy – to – follow replacement procedure. Also, keep the board clean from dust and debris, as these can affect the performance of the relays over time.

Product Guarantee

GE stands firmly behind the quality of the GE DS200RTBAG2AFB. The board is manufactured to high – quality standards, undergoing rigorous testing to ensure its reliability in industrial applications. In the event of a defect in materials or workmanship during the warranty period, GE will provide repair or replacement services at no cost to the customer. Their dedicated technical support team is available to assist with any installation – related questions, as well as to troubleshoot any issues that may arise during the board’s operation. This commitment to quality and customer support reflects GE’s confidence in the DS200RTBAG2AFB and its ability to meet the demanding requirements of industrial control systems.