Description

Product Overview

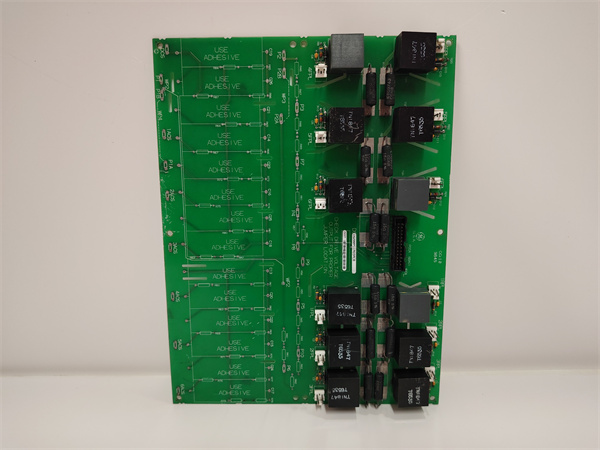

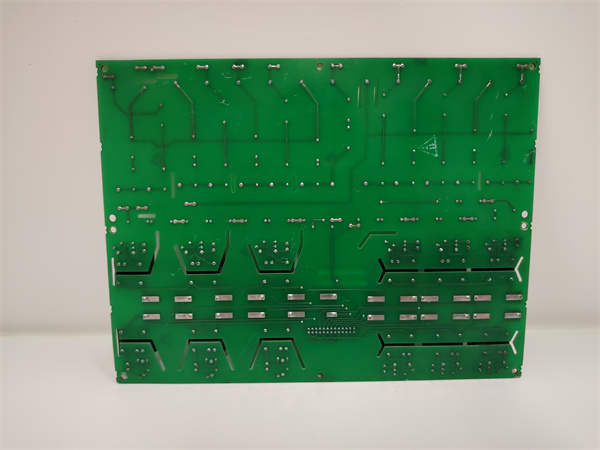

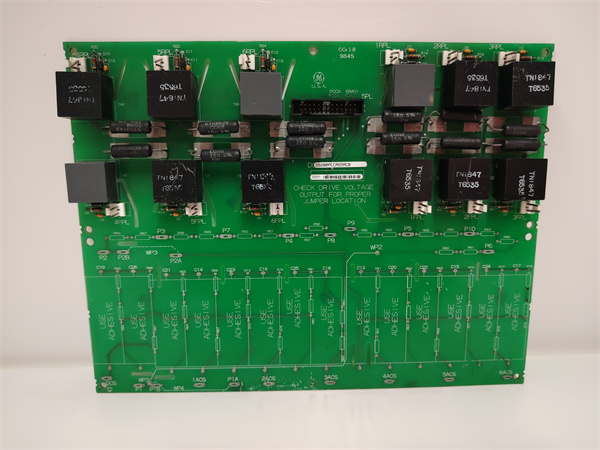

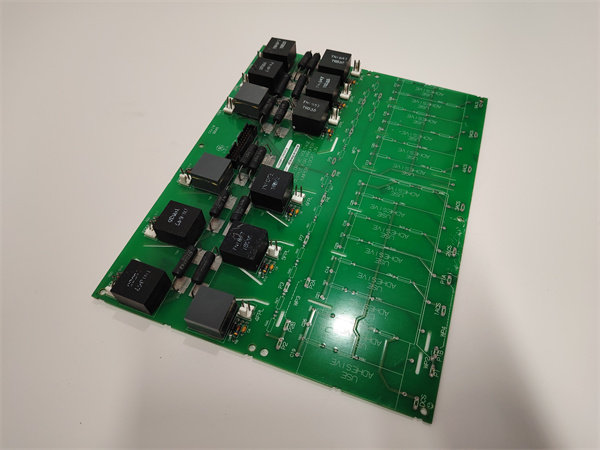

The GE DS200PCCAG5ACB is a significant component in General Electric’s industrial automation lineup. It is a printed circuit board designed as part of the Mark V series, which is renowned for its reliability and performance in industrial control systems. This board plays a crucial role in the overall functionality of the Mark V system, handling various control and communication tasks.

The GE DS200PCCAG5ACB is engineered to interface with other modules in the system, enabling seamless data transfer and control signal processing. It is responsible for managing the flow of information between different components, ensuring that the industrial process operates smoothly. Whether it’s in a power generation plant, a manufacturing facility, or a process control environment, this board contributes to the precision and efficiency of the system. It can handle a variety of input and output signals, making it adaptable to different industrial applications and requirements.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS200PCCAG5ACB |

| Manufacturer | General Electric |

| Product Type | Printed Circuit Board |

| Series | Mark V |

| Input Voltage Range | 18 – 30 VDC |

| Output Voltage Range | Suitable for the system’s requirements |

| Operating Temperature Range | – 40 °C to + 70 °C |

| Communication Interfaces | Serial communication interfaces for data transfer |

| Dimensions | [Length] x [Width] x [Height] (in mm) |

| Weight | [Weight in kg] |

| Number of Connectors | [Specify the number] |

| Isolation Voltage | [Isolation voltage value in V] |

| Data Transfer Rate | [Data transfer rate in bits per second] |

| Power Consumption | [Power consumption in watts] |

DS200PCCAG5ACB

Main Features and Advantages

Robust Communication Capabilities

The GE DS200PCCAG5ACB is equipped with serial communication interfaces, enabling reliable data transfer between different modules in the Mark V system. It can handle a wide range of data rates, ensuring that information is transmitted accurately and in a timely manner. This feature is essential for maintaining the integrity of the control system, especially in applications where real-time data exchange is critical.

Wide Temperature Tolerance

With an operating temperature range of – 40 °C to + 70 °C, the GE DS200PCCAG5ACB can function effectively in various environmental conditions. This makes it suitable for installation in harsh industrial settings, such as offshore platforms, where temperature fluctuations can be significant. The board’s ability to operate in extreme temperatures ensures continuous and reliable performance.

High Isolation Voltage

The GE DS200PCCAG5ACB has a high isolation voltage, which provides excellent protection against electrical interference and voltage surges. This isolation helps to safeguard the board and other components in the system from potential damage caused by electrical transients. It also enhances the reliability of the system by reducing the risk of signal interference, ensuring stable operation even in electrically noisy environments.

Compatibility with Mark V System

As a part of the Mark V series, the GE DS200PCCAG5ACB is fully compatible with other modules in the system. This compatibility simplifies system integration and reduces the risk of compatibility issues. It allows for easy expansion and customization of the control system, enabling users to meet their specific industrial requirements.

Application Field

Power Generation

In power generation plants, the GE DS200PCCAG5ACB is used in the control systems of gas and steam turbines. It monitors and controls various parameters, such as turbine speed, temperature, and pressure. By accurately processing input signals from sensors and sending control signals to actuators, it ensures the efficient and safe operation of the turbines, optimizing power generation processes.

Manufacturing Industry

In manufacturing facilities, this board is employed in automated production lines. It controls the operation of robotic arms, conveyor belts, and other equipment, ensuring smooth production processes. For example, in an automotive manufacturing plant, the GE DS200PCCAG5ACB can be used to manage the movement of parts and the operation of machinery, enhancing productivity and product quality.

Process Control

In industries such as chemical, oil and gas, and water treatment, the GE DS200PCCAG5ACB plays a vital role in process control. It interfaces with sensors and valves to regulate process variables, ensuring that the production processes are carried out within the desired parameters. Whether it’s controlling the flow of chemicals in a chemical plant or the treatment of water in a water treatment facility, this board contributes to the overall efficiency and reliability of the process control system.

DS200PCCAG5ACB

Related Products

GE DS200PCCAG3A: This is another printed circuit board in the Mark V series. It may have different functionality or specifications compared to the GE DS200PCCAG5ACB, such as different communication interfaces or power handling capabilities. It can be used in similar industrial applications but may be optimized for specific tasks within the control system.

GE Mark V Controllers: These controllers work in conjunction with the GE DS200PCCAG5ACB. They receive input from the board and make control decisions based on the data processed by the board. The controllers are responsible for managing the overall operation of the Mark V system, and the GE DS200PCCAG5ACB provides the necessary necessary data and control signals to support their functions.

GE I/O Modules: Various I/O modules in the Mark V series, such as digital input/output modules and analog input/output modules, interact with the GE DS200PCCAG5ACB. These I/O modules are used to interface with field devices, such as sensors and actuators, and the board is responsible for processing the signals from these modules and communicating with the controllers.

GE Power Supplies: Specific power supplies designed for the Mark V system are related to the GE DS200PCCAG5ACB. These power supplies ensure a stable and reliable power source for the board and other components in the system. They are crucial for maintaining the proper operation of the control system, especially in industrial environments where power stability is essential.

Installation and Maintenance

Pre-installation preparation: Before installing the GE DS200PCCAG5ACB, ensure that the power to the control system is turned off to prevent electrical accidents. Check the physical condition of the board for any signs of damage during transit. Verify the compatibility of the board with other components in the system, and ensure that the installation environment meets the specified temperature and humidity requirements. Follow the installation manual provided by GE to correctly connect the board to other modules and power sources.

Maintenance recommendations: Regularly inspect the GE DS200PCCAG5ACB for any signs of physical damage, such as cracks or loose connections. Monitor the operating temperature and humidity of the installation environment to ensure they are within the specified ranges. Check the communication interfaces for any signs of malfunction, such as data transfer errors. If any issues are detected, refer to the troubleshooting guide in the product manual or contact GE’s technical support for assistance. Periodically clean the board to remove dust and debris, which can affect its performance.

Product Guarantee

General Electric offers a comprehensive product guarantee for the GE DS200PCCAG5ACB. The product undergoes rigorous testing before leaving the factory to ensure it meets high-quality standards. GE provides a standard warranty period, during which, if the board shows any manufacturing defects, they will offer repair or replacement services free of charge. Their team of technical experts is available to provide support for installation, operation, and troubleshooting. This commitment to quality and customer service reflects GE’s confidence in the reliability and performance of the GE DS200PCCAG5ACB, giving customers peace of mind when using this product in their industrial automation systems.