Description

Product Overview

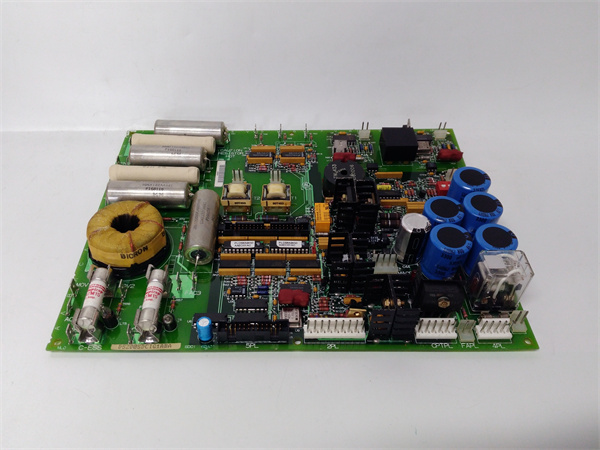

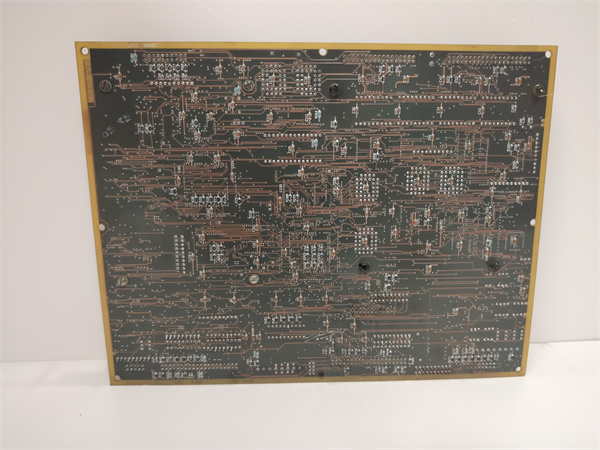

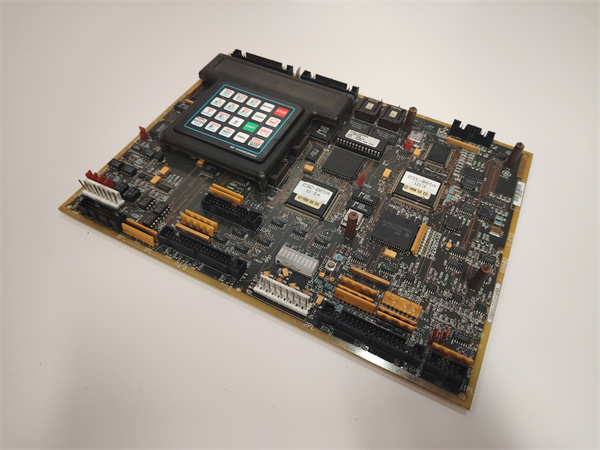

The GE DS200FSAAG1ABA is a high – performance module that plays a pivotal role in industrial automation and control systems, being an integral part of GE’s Mark VI series. This module is specifically designed as a servo I/O terminal board, offering a wide range of functionalities crucial for smooth industrial operations.

It features two servo outputs, which are essential for accurately controlling the movement and operation of servo – based machinery. Additionally, it provides I/O capabilities for six LVDT (Linear Variable Differential Transformer) position sensors. These sensors are widely used in industrial settings to precisely measure linear displacements, and the GE DS200FSAAG1ABA ensures seamless communication between these sensors and the overall control system. Moreover, it comes with two active pulse rate inputs for flow monitoring, enabling real – time and accurate tracking of fluid flow in various industrial processes. This makes the GE DS200FSAAG1ABA a comprehensive solution for applications that require high – precision control and monitoring within industrial automation setups.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS200FSAAG1ABA |

| Manufacturer | General Electric |

| Product Type | Servo I/O Terminal Board |

| Number of Servo Outputs | 2 |

| Number of LVDT Position Sensor I/O | 6 |

| Number of Active Pulse Rate Inputs | 2 |

| Input Logic | Compatible with relevant industrial standards |

| Output Signal Range | Varies according to connected devices |

| Isolation Voltage | High – voltage isolation for safety |

| Operating Temperature Range | – 40 °C to + 85 °C |

| Storage Temperature Range | – 40 °C to + 85 °C |

| Dimensions | [Specify if available] |

| Weight | [Specify if available] |

DS200LDCCH1AKA

Main Features and Advantages

Comprehensive I/O Capabilities: The GE DS200FSAAG1ABA offers a diverse set of I/O options. With two servo outputs, it can effectively control servo – driven equipment, ensuring precise motion control. The six LVDT position sensor I/O and two active pulse rate inputs for flow monitoring make it suitable for complex industrial applications where multiple types of data need to be processed and controlled simultaneously. This comprehensive I/O setup reduces the need for multiple separate modules, simplifying the system architecture and potentially lowering costs.

Reliable in Harsh Environments: Designed to withstand extreme conditions, this module has an operating temperature range of – 40 °C to + 85 °C. This allows it to be used in various industrial environments, from cold storage facilities to high – temperature manufacturing plants. Whether it’s exposed to intense heat during metal smelting processes or extreme cold in refrigerated warehouses, the GE DS200FSAAG1ABA maintains its reliable performance, ensuring continuous operation of the industrial control system.

High – Precision Signal Handling: For the LVDT position sensors, the module is optimized to handle their signals with high precision. This is crucial in applications where accurate position measurement is vital, such as in robotic arms used in manufacturing or precision – controlled machinery in the aerospace industry. The accurate handling of these signals contributes to the overall precision and efficiency of the industrial processes, reducing errors and improving product quality.

Reliable in Harsh Environments: Designed to withstand extreme conditions, this module has an operating temperature range of – 40 °C to + 85 °C. This allows it to be used in various industrial environments, from cold storage facilities to high – temperature manufacturing plants. Whether it’s exposed to intense heat during metal smelting processes or extreme cold in refrigerated warehouses, the GE DS200FSAAG1ABA maintains its reliable performance, ensuring continuous operation of the industrial control system.

High – Precision Signal Handling: For the LVDT position sensors, the module is optimized to handle their signals with high precision. This is crucial in applications where accurate position measurement is vital, such as in robotic arms used in manufacturing or precision – controlled machinery in the aerospace industry. The accurate handling of these signals contributes to the overall precision and efficiency of the industrial processes, reducing errors and improving product quality.

Application Field

Manufacturing Industry: In manufacturing plants, the GE DS200FSAAG1ABA is extensively used. For example, in automotive manufacturing, it can control the servo – based movement of robotic arms that assemble car parts. The LVDT position sensors, connected through this module, can precisely measure the position of the robotic arms, ensuring accurate part placement. In addition, the active pulse rate inputs can monitor the flow of lubricants or coolants in the manufacturing equipment, maintaining optimal operating conditions.

Power Generation: In power plants, whether they are thermal, hydro, or wind – powered, this module plays a significant role. In thermal power plants, it can control the servo – actuated valves that regulate the flow of steam or fuel. The accurate position monitoring of these valves, facilitated by the LVDT sensors connected to the GE DS200FSAAG1ABA, is crucial for maintaining stable power generation. In wind power plants, it can be used to control the pitch and yaw of wind turbine blades, optimizing energy capture.

Industrial Automation in General: In any industrial setup where automation is key, this module finds its application. It can be used in conveyor belt systems, where the servo outputs can control the speed and movement of the belts, and the flow monitoring inputs can ensure proper material flow. In packaging industries, it can control the movement of packaging machinery and monitor the flow of packaging materials, ensuring efficient and accurate packaging processes.

Power Generation: In power plants, whether they are thermal, hydro, or wind – powered, this module plays a significant role. In thermal power plants, it can control the servo – actuated valves that regulate the flow of steam or fuel. The accurate position monitoring of these valves, facilitated by the LVDT sensors connected to the GE DS200FSAAG1ABA, is crucial for maintaining stable power generation. In wind power plants, it can be used to control the pitch and yaw of wind turbine blades, optimizing energy capture.

Industrial Automation in General: In any industrial setup where automation is key, this module finds its application. It can be used in conveyor belt systems, where the servo outputs can control the speed and movement of the belts, and the flow monitoring inputs can ensure proper material flow. In packaging industries, it can control the movement of packaging machinery and monitor the flow of packaging materials, ensuring efficient and accurate packaging processes.

Related Products

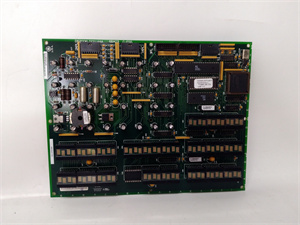

GE DS200FSAAG1A: A related model that likely shares some fundamental features with the GE DS200FSAAG1ABA. It may have differences in specific I/O configurations or performance parameters, making it suitable for applications with slightly different requirements.

GE DS200FSAAG2ABA: This model might have variations in terms of its functionality, perhaps with different capabilities in handling servo outputs or sensor inputs. It could be designed for more specialized industrial applications compared to the GE DS200FSAAG1ABA.

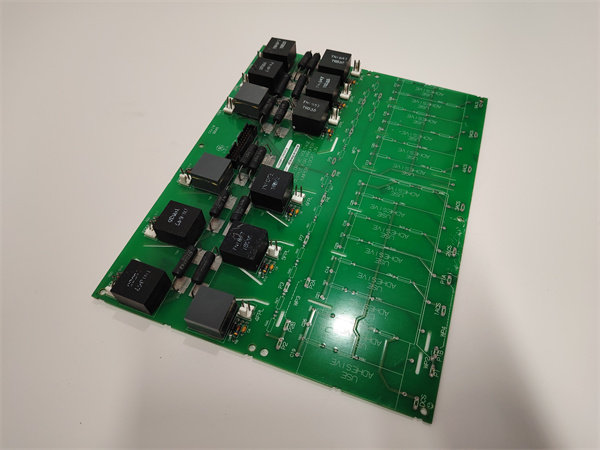

GE Mark VI Control Modules: These are other control modules within the Mark VI series that work in tandem with the GE DS200FSAAG1ABA. They provide the overall control logic and communicate with the DS200FSAAG1ABA to manage the connected I/O devices and execute control commands.

GE LVDT Position Sensors: These are the sensors that can be connected to the GE DS200FSAAG1ABA module. Different models of LVDT sensors may vary in terms of their measurement range, accuracy, and environmental resistance, and are selected based on the specific needs of the industrial application.

GE Servo – Driven Equipment: The servo – based machinery that the GE DS200FSAAG1ABA controls. Different types of servo – driven equipment, such as robotic arms, servo motors, and actuators, have their own unique specifications and are integrated with the module to achieve precise control in industrial processes.

GE DS200FSAAG2ABA: This model might have variations in terms of its functionality, perhaps with different capabilities in handling servo outputs or sensor inputs. It could be designed for more specialized industrial applications compared to the GE DS200FSAAG1ABA.

GE Mark VI Control Modules: These are other control modules within the Mark VI series that work in tandem with the GE DS200FSAAG1ABA. They provide the overall control logic and communicate with the DS200FSAAG1ABA to manage the connected I/O devices and execute control commands.

GE LVDT Position Sensors: These are the sensors that can be connected to the GE DS200FSAAG1ABA module. Different models of LVDT sensors may vary in terms of their measurement range, accuracy, and environmental resistance, and are selected based on the specific needs of the industrial application.

GE Servo – Driven Equipment: The servo – based machinery that the GE DS200FSAAG1ABA controls. Different types of servo – driven equipment, such as robotic arms, servo motors, and actuators, have their own unique specifications and are integrated with the module to achieve precise control in industrial processes.

Installation and Maintenance

Pre – installation preparation: Before installing the GE DS200FSAAG1ABA, ensure that the power supply to the industrial control system is switched off to prevent electrical hazards. Thoroughly inspect the module for any visible signs of damage during transportation. Familiarize yourself with the installation manual, which details the proper mounting of the module in the control cabinet. When connecting wires to the module, make sure to use the correct wire gauges as per the specifications. Verify the compatibility of the module with other components in the system, especially the control modules and the sensors/actuators it will be connected to.

Maintenance recommendations: Regularly monitor the GE DS200FSAAG1ABA for any signs of abnormal operation. Check the status of the servo outputs and sensor inputs to ensure they are functioning correctly. Clean the module periodically to remove dust and debris, as these can affect its performance, especially in dusty industrial environments. If any issues arise, refer to the product manual for troubleshooting steps. In case of component failure, replace the faulty parts with genuine GE – approved components to maintain the integrity and performance of the module.

Product Guarantee

General Electric stands firmly behind the quality of the GE DS200FSAAG1ABA. The module undergoes rigorous testing during the manufacturing process to meet high – industry standards. GE offers a comprehensive product guarantee, which includes a warranty period. During this time, if there are any defects in materials or workmanship, GE will provide repair or replacement services free of charge. Their team of technical experts is available around the clock to offer support for installation, configuration, and troubleshooting. This reflects GE’s confidence in the product and its commitment to ensuring customer satisfaction in industrial automation applications.