Description

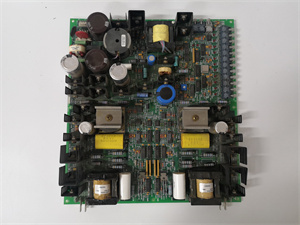

GE DS200FGPAG1AHD

Product Overview

The GE DS200FGPAG1AHD is a high-performance Gate Pulse Amplifier Board designed for GE’s Mark V series of turbine control systems. Engineered to deliver precise power management and real-time feedback control, this module serves as a critical component in Load Commutated Inverter (LCI) applications, particularly in gas and steam turbine systems. As part of GE’s legacy industrial control solutions, the DS200FGPAG1AHD integrates advanced circuit design to provide gate power amplification, SCR (Silicon-Controlled Rectifier) status monitoring, and AC-to-DC power conversion, ensuring seamless operation in mission-critical environments .

The GE DS200FGPAG1AHD is a high-performance Gate Pulse Amplifier Board designed for GE’s Mark V series of turbine control systems. Engineered to deliver precise power management and real-time feedback control, this module serves as a critical component in Load Commutated Inverter (LCI) applications, particularly in gas and steam turbine systems. As part of GE’s legacy industrial control solutions, the DS200FGPAG1AHD integrates advanced circuit design to provide gate power amplification, SCR (Silicon-Controlled Rectifier) status monitoring, and AC-to-DC power conversion, ensuring seamless operation in mission-critical environments .

The DS200FGPAG1AHD supports a wide input voltage range (120 Vrms ±20%, 50/60 Hz) and features 15 fiber-optic connectors for high-speed data transmission, enabling reliable communication with LCI controllers and field devices. Its architecture includes dual gate driver circuits and 30 test points (nine for Gate A, nine for Gate B, and 12 for cell status monitoring), allowing technicians to diagnose and optimize system performance efficiently . Positioned as a cornerstone in turbine control systems, the DS200FGPAG1AHD enhances system reliability by incorporating redundant protection mechanisms, such as fuse-protected circuits and diagnostic LEDs, ensuring continuous operation even in harsh industrial conditions.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DS200FGPAG1AHD |

| Manufacturer | GE |

| Product Type | Gate Pulse Amplifier Board |

| Input Voltage | 120 Vrms ±20%, 50/60 Hz |

| Maximum Power | 350 VA |

| Output Voltage | DC control voltages (e.g., 24 VDC, 48 VDC) |

| Communication Interface | Fiber-optic links (15 connectors) |

| Test Points | 30 (9 for Gate A, 9 for Gate B, 12 for cell status) |

| Physical Dimensions | N/A (similar to DS200FGPAG1A: 20 × 16 × 16 inches) |

| Weight | N/A (similar to DS200FGPAG1A: 1 lb 3 oz) |

| Operating Temperature | -20°C to 60°C (industry-standard for Mark V modules) |

| Installation Method | Backplane-mounted with snap-lock connectors |

| Warranty | 1–3 years (varies by distributor, with GE’s standard coverage typically 1 year) |

DS200FGPAG1AHD

Main Features and Advantages

High-Precision Gate Power Amplification: The DS200FGPAG1AHD provides gate power for one phase of the SCR bridge, ensuring accurate triggering of thyristors in LCI systems. This precision is critical for maintaining stable power output in gas turbines and other high-power applications .

High-Precision Gate Power Amplification: The DS200FGPAG1AHD provides gate power for one phase of the SCR bridge, ensuring accurate triggering of thyristors in LCI systems. This precision is critical for maintaining stable power output in gas turbines and other high-power applications .

Comprehensive SCR Status Monitoring: Equipped with 12 test points for cell status monitoring, the module collects voltage data from up to 12 Field-Programmable Gate Array (FPGA) boards and relays this information via an optical serial data link to the LCI controller. This real-time feedback enables proactive maintenance and reduces unplanned downtime .

Robust Power Conversion: The module’s switching power supply converts AC input to DC control voltages required for gating and status functions. It supports multiple voltage inputs (e.g., P15: 13.5–14.5 VDC, P5: 4.7–5.1 VDC) and ensures stable output even under fluctuating input conditions .

High-Speed Fiber-Optic Communication: With 15 fiber-optic connectors, the DS200FGPAG1AHD facilitates fast and interference-free data transmission, making it suitable for environments with high electromagnetic noise. This feature is essential for synchronizing control signals in distributed turbine systems .

Modular Design for Easy Integration: Designed for seamless compatibility with GE’s Mark V series, the DS200FGPAG1AHD uses snap-lock connectors and jumper-configurable settings, simplifying installation and retrofitting. Its compact form factor optimizes space in control cabinets .

Application Field

The GE DS200FGPAG1AHD excels in mission-critical industrial environments, particularly in power generation and heavy machinery control. In gas and steam turbine systems, it powers drive systems and provides feedback for speed and load regulation, ensuring efficient energy conversion. For example, in a power plant, the module stabilizes power supply to turbine control systems, maintaining consistent output voltage and frequency .

The GE DS200FGPAG1AHD excels in mission-critical industrial environments, particularly in power generation and heavy machinery control. In gas and steam turbine systems, it powers drive systems and provides feedback for speed and load regulation, ensuring efficient energy conversion. For example, in a power plant, the module stabilizes power supply to turbine control systems, maintaining consistent output voltage and frequency .

In oil and gas facilities, the DS200FGPAG1AHD supports remote pump stations and offshore platforms by providing reliable gate pulse amplification and SCR monitoring. Its wide input voltage range and robust protection mechanisms make it suitable for applications with unstable power sources .

The module also finds use in industrial automation for metal smelting, water treatment, and textile machinery. Its dual gate driver circuits and fiber-optic communication enable precise control of motor-driven processes, such as conveyor belts and robotic arms. Additionally, in HVAC systems, the DS200FGPAG1AHD regulates power to variable-speed drives, optimizing energy consumption .

DS200FGPAG1AHD

Related Products

- DS200TCQAG1B: A turbine communication module for Mark V systems, enabling data exchange between the DS200FGPAG1AHD and higher-level controllers.

- DS200PCAG9ACB: A power connect card that interfaces with the DS200FGPAG1AHD to distribute power across the Mark V system.

- DS200FGPAG1AKD: A variant with functional revisions, offering enhanced SCR monitoring capabilities for specific LCI configurations.

- DS200GDPAG1: A high-frequency power supply board that complements the DS200FGPAG1AHD in Mark V drive systems, providing stable DC power for control functions .

- IS200TCCBG1B (Mark VIe): A newer-generation module for gas turbine control, serving as an upgrade path for legacy Mark V systems.

Installation and Maintenance

Pre-installation preparation: Ensure the system is powered off and capacitors are discharged. Verify backplane compatibility and jumper settings against the replaced module. Use anti-static precautions to handle the DS200FGPAG1AHD, as electrostatic discharge can damage sensitive components. Inspect fiber-optic connectors for debris and ensure proper alignment during installation .

Pre-installation preparation: Ensure the system is powered off and capacitors are discharged. Verify backplane compatibility and jumper settings against the replaced module. Use anti-static precautions to handle the DS200FGPAG1AHD, as electrostatic discharge can damage sensitive components. Inspect fiber-optic connectors for debris and ensure proper alignment during installation .

Maintenance recommendations: Regularly inspect the module for physical damage and loose connections. Monitor voltage levels using the onboard test points and replace fuses if tripped. Clean dust accumulation to prevent overheating. Update firmware periodically to address compatibility issues with newer Mark V system software. For advanced diagnostics, use GE’s proprietary tools to analyze SCR status data transmitted via fiber-optic links .

Product Guarantee

GE stands behind the DS200FGPAG1AHD with a comprehensive quality assurance program. The module is rigorously tested to meet industry standards, with a typical warranty period of 1 year (extendable to 3 years through authorized distributors). GE’s global support network provides technical assistance for installation, troubleshooting, and replacement, ensuring minimal downtime. In the event of a defect, GE offers prompt repair or replacement, reflecting its commitment to delivering reliable industrial control solutions .

GE stands behind the DS200FGPAG1AHD with a comprehensive quality assurance program. The module is rigorously tested to meet industry standards, with a typical warranty period of 1 year (extendable to 3 years through authorized distributors). GE’s global support network provides technical assistance for installation, troubleshooting, and replacement, ensuring minimal downtime. In the event of a defect, GE offers prompt repair or replacement, reflecting its commitment to delivering reliable industrial control solutions .

By combining advanced gate pulse amplification, real-time SCR monitoring, and rugged design, the GE DS200FGPAG1AHD sets a benchmark for performance in industrial automation and turbine control systems. Its compatibility with GE’s Mark V series and ability to operate in harsh environments make it an ideal choice for critical infrastructure applications.