Description

Product Overview

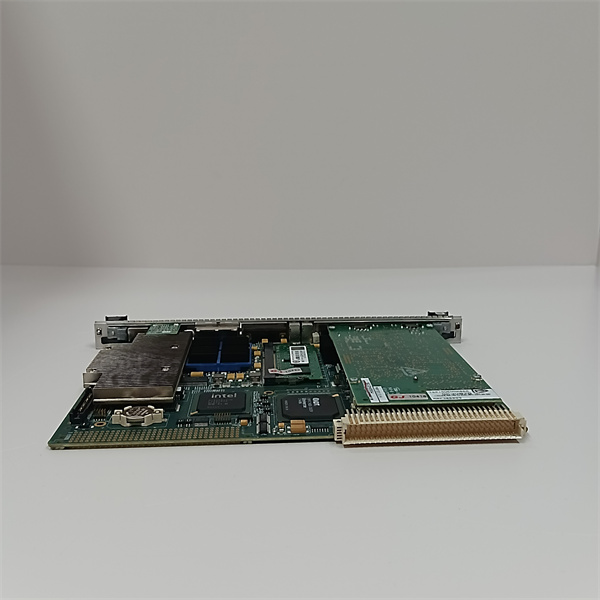

The GE D20EME10BASE – T 820 – 0474 is a specialized Ethernet communication module developed by General Electric, designed to enhance the connectivity and data transfer capabilities within industrial automation systems. As a key component in the realm of industrial networking, this module is engineered to enable seamless communication between various devices, such as programmable logic controllers (PLCs), human – machine interfaces (HMIs), and other intelligent devices in the industrial ecosystem.

Built with advanced Ethernet technology, the GE D20EME10BASE – T 820 – 0474 provides a reliable and high – speed data transfer pathway. It adheres to the 10BASE – T standard, which ensures compatibility with a wide range of existing network infrastructure. This module is positioned as a crucial enabler for modern industrial automation, facilitating real – time monitoring, control, and data exchange. By integrating the GE D20EME10BASE – T 820 – 0474 into industrial systems, manufacturers can improve operational efficiency, optimize processes, and gain valuable insights through the seamless flow of data across the network.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | D20EME10BASE – T 820 – 0474 |

| Manufacturer | General Electric |

| Product Type | Ethernet Communication Module |

| Communication Standard | 10BASE – T |

| Data Transfer Rate | 10 Mbps |

| Interface Type | RJ45 |

| Power Supply | 24 VDC |

| Operating Temperature Range | -20 °C to +60 °C |

| Dimensions | [Not provided, consult product manual] |

| Weight | [Not provided, consult product manual] |

| Network Protocol Support | TCP/IP, UDP |

| LED Indicators | Link status, data activity |

| Number of Network Ports | 1 |

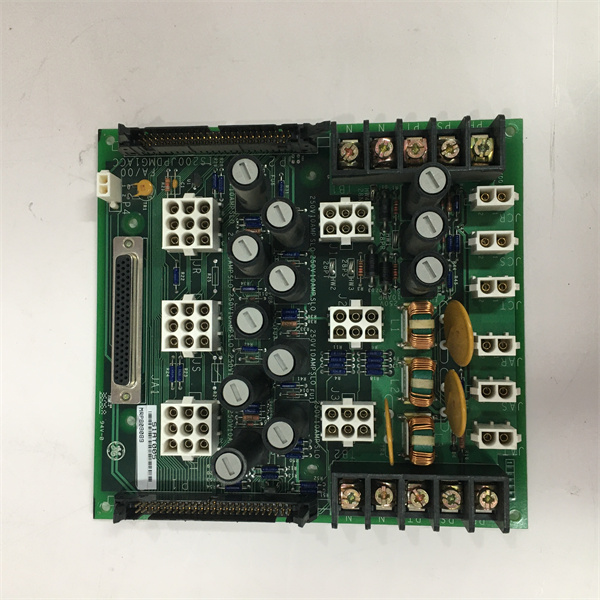

IS200JPDMG1ACC S1AT005

Main Features and Advantages

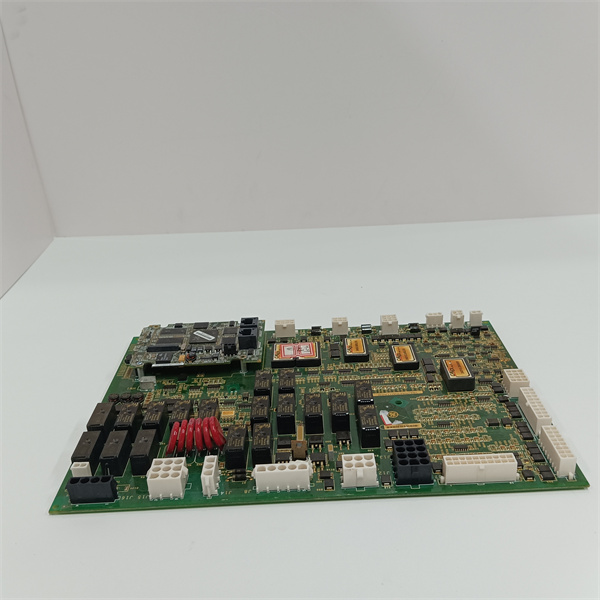

Reliable Connectivity

The GE D20EME10BASE – T 820 – 0474 offers stable and reliable Ethernet connectivity. With its RJ45 interface and adherence to the 10BASE – T standard, it ensures a consistent connection to the network, minimizing the risk of data dropouts. This reliability is crucial in industrial environments where uninterrupted communication between devices is essential for smooth operation. For example, in a continuous manufacturing process, any disruption in data transfer could lead to production delays or quality issues, and the GE D20EME10BASE – T 820 – 0474 helps prevent such scenarios.

Compatibility

This module is highly compatible with a wide range of industrial devices and network systems. Its support for standard network protocols like TCP/IP and UDP allows it to integrate seamlessly with existing PLCs, HMIs, and other control systems from various manufacturers. This compatibility reduces the complexity of system integration and enables easy expansion of industrial automation networks. Whether upgrading an older system or building a new one, the GE D20EME10BASE – T 820 – 0474 can be readily incorporated without significant compatibility challenges.

Real – Time Data Transfer

With a data transfer rate of 10 Mbps, the GE D20EME10BASE – T 820 – 0474 enables real – time data transfer. This is essential for applications that require immediate feedback and control, such as in automated production lines. For instance, sensors can send real – time data on product quality or machine status to the control system through this module, allowing for prompt adjustments and optimizations. The real – time data transfer capability also supports remote monitoring and control, enabling operators to manage industrial processes from a central location.

User – Friendly Operation

The module features intuitive LED indicators that display the link status and data activity. These indicators provide quick visual feedback, allowing operators to easily monitor the module’s operation and identify any potential issues. This user – friendly design simplifies maintenance and troubleshooting, reducing the time and effort required to keep the industrial network running smoothly. Even non – technical personnel can quickly understand the module’s status at a glance, enhancing overall system usability.

Application Field

Manufacturing Industry

In manufacturing plants, the GE D20EME10BASE – T 820 – 0474 is used to connect various production equipment, such as CNC machines, robotic arms, and conveyor systems, to the plant’s control network. This enables real – time monitoring of production processes, allowing for immediate detection of bottlenecks or quality issues. For example, if a robotic arm on an assembly line experiences a malfunction, sensors can send data through the GE D20EME10BASE – T 820 – 0474 to the central control system, which can then initiate corrective actions, reducing downtime and improving productivity.

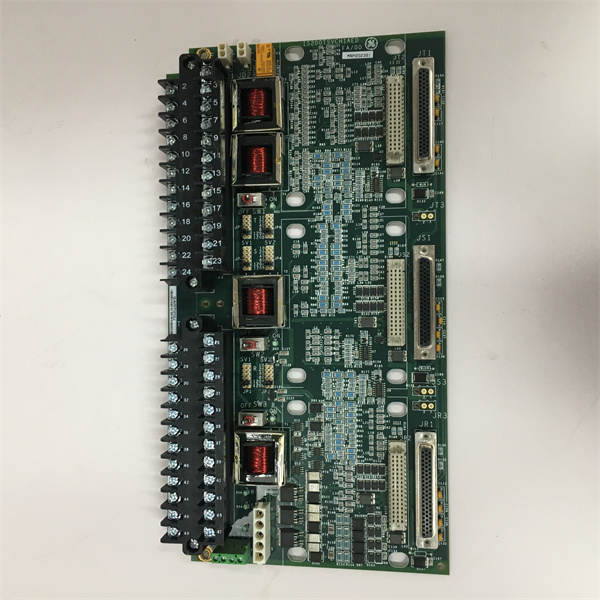

Power Generation

In power plants, this Ethernet communication module is employed to connect generators, turbines, and other critical equipment to the plant’s monitoring and control systems. It enables the transfer of real – time data on parameters such as voltage, current, and temperature, allowing operators to monitor the performance of power – generating equipment and make informed decisions. In the event of an abnormal condition, the GE D20EME10BASE – T 820 – 0474 ensures that the relevant data is quickly transmitted to the control center, enabling timely responses to prevent potential failures.

Oil and Gas Industry

Within the oil and gas sector, the GE D20EME10BASE – T 820 – 0474 is used to connect sensors, valves, and pumps in oil rigs, refineries, and pipelines to the control network. It facilitates the remote monitoring and control of operations, improving safety and efficiency. For example, in a pipeline, sensors can detect leaks or pressure anomalies and send data through the module to the central control system. Operators can then take appropriate actions, such as shutting off valves or dispatching repair teams, to minimize the impact of potential incidents.

VME-PMC-CADDY

Related Products

GE D20EME100BASE – TX

This is a similar Ethernet communication module by GE but with a higher data transfer rate of 100 Mbps, suitable for applications that require faster data transfer. While the GE D20EME10BASE – T 820 – 0474 offers 10 Mbps, the D20EME100BASE – TX can handle more data – intensive tasks, such as high – definition video streaming for remote surveillance in industrial settings.

GE IC693ETM200

An Ethernet interface module for GE’s 90 – 30 series PLCs. It can be used in conjunction with the GE D20EME10BASE – T 820 – 0474 to enhance the communication capabilities of the PLC – based systems. The IC693ETM200 provides additional functionality for PLC – specific network integration, while the D20EME10BASE – T 820 – 0474 offers general – purpose Ethernet connectivity.

GE VersaMax Ethernet Interface Module

This module is designed for use with GE’s VersaMax family of controllers. It complements the GE D20EME10BASE – T 820 – 0474 by providing a dedicated interface for the VersaMax controllers, enabling seamless communication between the controllers and other devices on the Ethernet network.

GE Proficy Machine Edition

A software suite that works with the GE D20EME10BASE – T 820 – 0474 to manage and monitor industrial networks. It provides tools for configuring network settings, monitoring data traffic, and troubleshooting issues. The software suite enhances the overall functionality of the communication module, allowing for more efficient network management.

GE Industrial Ethernet Switches

These switches are used to expand the network infrastructure when using the GE D20EME10BASE – T 820 – 0474. They provide additional network ports for connecting multiple devices, enabling the creation of larger and more complex industrial Ethernet networks.

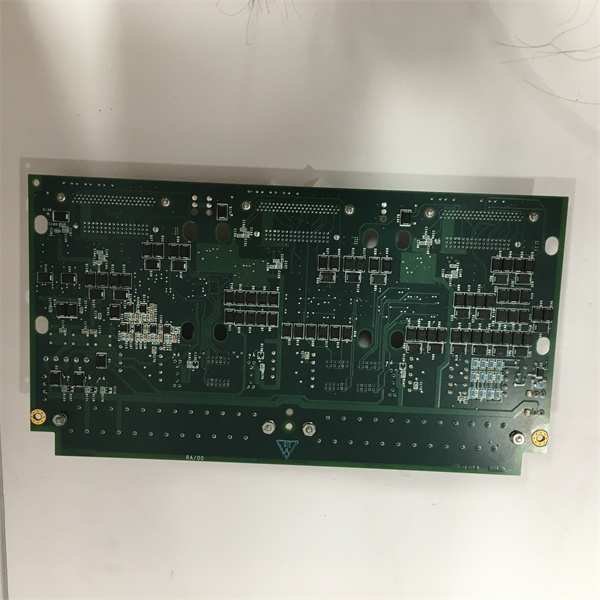

Installation and Maintenance

Pre – installation preparation: Before installing the GE D20EME10BASE – T 820 – 0474, ensure that the power supply to the installation area is turned off to prevent electrical hazards. Check the network infrastructure to ensure that it is compatible with the 10BASE – T standard and that the RJ45 ports are in good condition. Familiarize yourself with the product manual, which provides detailed instructions on the physical installation and electrical connections. Verify that the 24 VDC power supply is available and meets the module’s requirements.

Maintenance recommendations: Regularly inspect the GE D20EME10BASE – T 820 – 0474 for any signs of physical damage, such as cracks or loose connections. Clean the module periodically to remove dust and debris, as these can affect its performance. Monitor the LED indicators to check for any abnormal behavior, such as a lack of link status or excessive data activity. If any issues are detected, refer to the product manual for troubleshooting steps. Periodically update the module’s firmware, if available, to ensure optimal performance and security.

Maintenance recommendations: Regularly inspect the GE D20EME10BASE – T 820 – 0474 for any signs of physical damage, such as cracks or loose connections. Clean the module periodically to remove dust and debris, as these can affect its performance. Monitor the LED indicators to check for any abnormal behavior, such as a lack of link status or excessive data activity. If any issues are detected, refer to the product manual for troubleshooting steps. Periodically update the module’s firmware, if available, to ensure optimal performance and security.

Product Guarantee

General Electric stands firmly behind the quality of the GE D20EME10BASE – T 820 – 0474. The product comes with a comprehensive quality assurance program. GE guarantees that the module is free from manufacturing defects for a specified period. In case of any defects during this warranty period, GE will provide repair or replacement services at no additional cost to the customer. Their global network of technical support teams is available around the clock to offer prompt assistance for installation guidance, troubleshooting, and any other technical issues. This reflects GE’s confidence in the reliability and performance of the GE D20EME10BASE – T 820 – 0474, ensuring customers can rely on it for their critical industrial communication needs.