Description

Product Overview

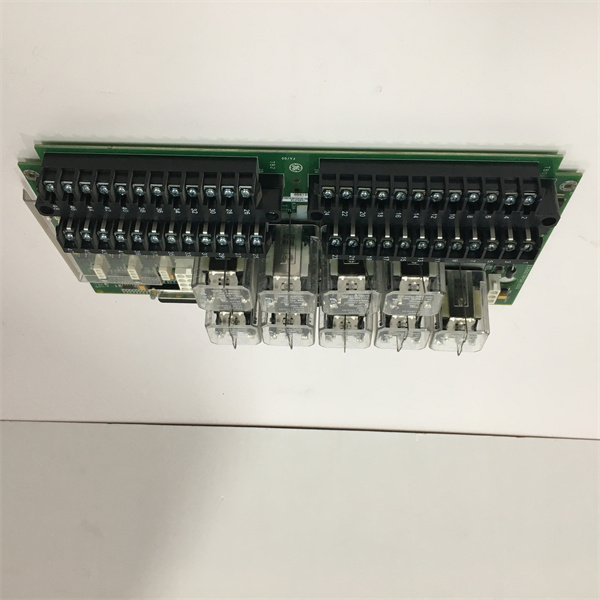

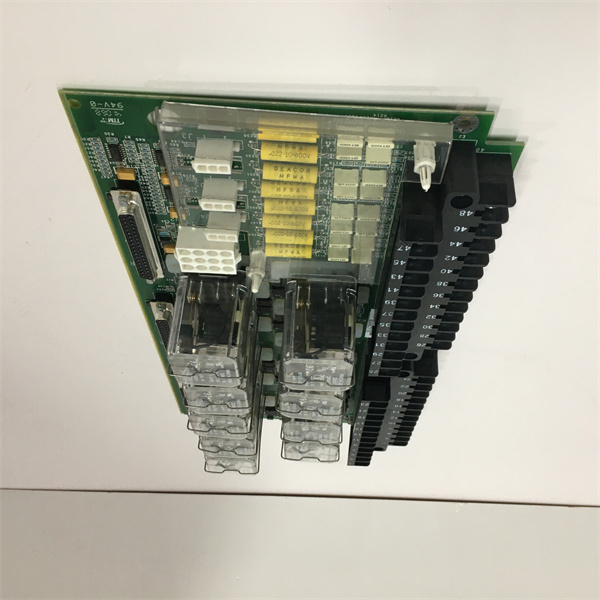

The GE CP238/TA1 is a high – performance control module designed for industrial automation systems by General Electric. It serves as a crucial component in various industrial setups, offering reliable and accurate control solutions. As part of GE’s comprehensive product lineup, the GE CP238/TA1 is engineered to meet the demanding requirements of modern industrial applications.

This module is particularly well – suited for applications that demand high – frequency operations. It ensures the generation of accurate and consistent control signals, which is vital for precise machinery and process control. The GE CP238/TA1 is often used in manufacturing processes, where it can regulate the speed and operation of motors, pumps, and other equipment with great precision. Additionally, in power generation facilities, it plays a key role in controlling the distribution and management of electrical power. Its compact design and robust construction make it easy to integrate into existing industrial systems, whether it’s a new installation or an upgrade of an old one.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | CP238/TA1 |

| Manufacturer | General Electric |

| Product Type | Control Module |

| Operating Voltage | 220V |

| Output Frequency | 50kHz |

| Configuration | PMC carrier, (1) 10/100 Ethernet connection, 66 MHz/64 bit interface, IPMI, hot swap with enum and blue light |

| Dual PMC Slots | Yes |

| PCI Bus | 32/64 bit wide and 33/66 MHz |

| Ethernet Port | 10 / 100 / 1000 BaseT X on the front panel |

| Primary and Secondary PCI Bus | Run asynchronously |

| Custom Processing | Available |

| Certified Product | Yes |

Main Features and Advantages

High – Frequency Performance

The GE CP238/TA1 is optimized for high – frequency operations. With an output frequency of 50kHz, it can generate control signals at a rapid pace. This is extremely beneficial in applications such as high – speed manufacturing lines, where quick and precise control of equipment is essential. For example, in a packaging plant with high – speed packaging machines, the GE CP238/TA1 can ensure that the machinery operates smoothly and accurately, maintaining high production rates without sacrificing quality.

Compact and Robust Design

This control module features a compact design, which allows for easy integration into existing industrial systems. Its small form factor doesn’t compromise on performance but rather enables it to fit into tight spaces, saving valuable panel space. Moreover, it is built with robust materials, making it resistant to harsh industrial environments. It can withstand factors such as dust, vibrations, and temperature fluctuations commonly found in industrial settings, ensuring long – term reliable operation.

Custom Processing Capability

The GE CP238/TA1 offers custom processing options. This means that it can be tailored to meet the specific requirements of different industrial applications. Whether it’s a unique control algorithm needed for a specialized manufacturing process or specific communication protocols required in a particular industrial network, the module can be configured accordingly. This flexibility makes it a versatile choice for a wide range of industries, from automotive manufacturing to chemical processing.

Ethernet Connectivity

Equipped with a 10/100 Ethernet connection, the GE CP238/TA1 enables seamless communication within the industrial network. It can easily interface with other devices such as sensors, actuators, and other control systems. This connectivity allows for real – time data transfer and remote monitoring and control. In a large – scale industrial facility, operators can monitor and adjust the module’s settings from a central control room, enhancing overall system efficiency and responsiveness.

{“deviceId”:”IOS_CE3C7C58-7E09-44BE-A3BA-72EFC57C93C4″,”openFrom”:”m2u_production”,”source”:”m2u”,”userId”:”1000000174898645″,”data”:{“beautyMode”:1,”mv”:[“15237795921965981582”]}}

Application Field

Manufacturing Industry

In manufacturing, the GE CP238/TA1 is widely used. In an automotive factory, it can control the movement of robotic arms on the assembly line. These arms need to move with high precision and at high speeds to pick and place parts accurately. The GE CP238/TA1‘s high – frequency output and custom processing capabilities make it an ideal choice for this task. In a food and beverage manufacturing plant, it can regulate the speed of conveyor belts, ensuring a smooth and consistent flow of products for packaging.

Power Generation

Power plants rely on the GE CP238/TA1 for various control functions. It can manage the operation of generators, controlling their speed and voltage output to ensure a stable power supply. In addition, it can be used to control the auxiliary equipment in power plants, such as pumps and fans that are crucial for cooling and other support systems. The module’s ability to handle high – frequency operations and its reliability in harsh environments make it suitable for the demanding conditions in power generation facilities.

Industrial Automation in General

For general industrial automation, the GE CP238/TA1 can be part of a larger control system. It can interface with different types of sensors and actuators to automate industrial processes. In a metalworking factory, it can control the operation of lathes, milling machines, and other machinery. By integrating with sensors that detect the position and status of the workpiece, the GE CP238/TA1 can adjust the machine’s operation in real – time, improving the quality of the finished products.

Related Products

CP238TA

Similar to the GE CP238/TA1, the CP238TA may have a slightly different configuration or feature set. It could potentially have a different variant of the same core technology, perhaps with a different focus on certain applications or a more cost – effective option for less demanding scenarios.

IC697PWR711 (GE Power Supply)

This power supply is related in that it can provide the necessary electrical power for the GE CP238/TA1 and other components in an industrial control system. A stable power supply is crucial for the proper functioning of the control module, and the IC697PWR711 is designed to meet the power requirements of such setups.

CM400RGICH1ACB (Unknown Function, but likely an industrial component)

While its exact function is not clear, it may be used in conjunction with the GE CP238/TA1 in an industrial system. It could be an interface module, a sensor, or an actuator that works together with the control module to achieve a specific industrial process.

D20 EME

This might be another control – related component. It could potentially be used in a different part of the industrial control system but may interact with the GE CP238/TA1 in some way. For example, it could be responsible for a specific sub – function that the GE CP238/TA1 coordinates with to ensure overall system operation.

12HGA11J52 (Instantaneous Auxiliary Relay)

In an industrial control setup, relays like the 12HGA11J52 can be controlled by the GE CP238/TA1. The control module can send signals to the relay to switch circuits on or off, which is useful in applications such as controlling the power supply to different pieces of equipment in an industrial process.

Installation and Maintenance

Pre – installation preparation: Before installing the GE CP238/TA1, ensure that the power to the industrial system is turned off. Check the physical dimensions of the module to make sure it can fit into the designated installation space. Verify that the operating voltage of the system matches the 220V requirement of the GE CP238/TA1. Inspect the connection ports, such as the Ethernet port, to ensure they are clean and free from damage. Make sure all the necessary mounting hardware is available and in good condition.

Maintenance recommendations: Regularly clean the GE CP238/TA1 to remove dust and debris that could accumulate over time and affect its performance. Check the Ethernet connection periodically to ensure stable communication. Monitor the module’s operating temperature and output frequency to detect any anomalies. If any issues are detected, refer to the product manual for troubleshooting steps. Replace any worn – out components promptly to maintain the reliability of the GE CP238/TA1.

Product Guarantee

General Electric stands firmly behind the quality of the GE CP238/TA1 control module. The product undergoes strict quality control during manufacturing to meet high – industry standards. GE offers a standard 1 – year warranty for the GE CP238/TA1. During this period, if there are any manufacturing defects, GE will provide repair or replacement services free of charge. Their global network of technical support teams is available to assist customers with installation, configuration, and troubleshooting. Whether it’s answering questions about the module’s operation or providing guidance on maintenance, customers can rely on GE’s expertise. This guarantee reflects GE’s confidence in the product and its commitment to providing reliable industrial control solutions, giving customers peace of mind when using the GE CP238/TA1 in their critical applications.