Description

1. Product Description

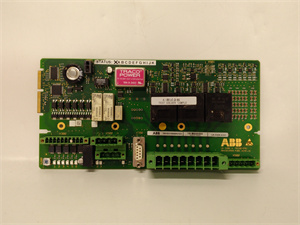

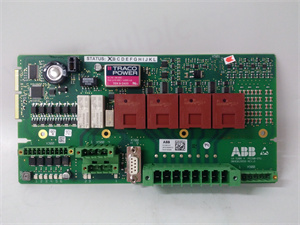

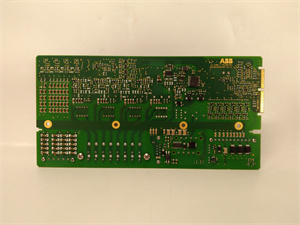

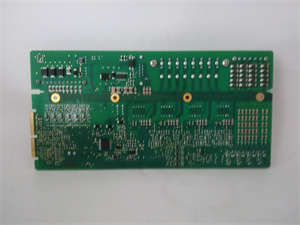

The ABB UAD206A101 is a high – performance analog input module designed for industrial automation and control systems. Manufactured by ABB, a globally recognized leader in power and automation technologies, the UAD206A101 is engineered to provide accurate and reliable data acquisition from various analog sensors. It plays a crucial role in converting analog signals from sensors, such as temperature, pressure, and voltage sensors, into digital signals that can be processed by programmable logic controllers (PLCs) or other control devices. This module is widely used in industrial applications where precise measurement and monitoring of analog variables are essential, offering excellent compatibility with ABB’s drive and control systems, which helps to simplify the overall system integration.

2. Product Parameters

- Input Channels: Multiple channels for connecting various analog sensors.

- Input Types: Support voltage, current, thermocouple, RTD, etc..

- Accuracy and Resolution: High – accuracy measurement with a fine resolution to ensure precise data acquisition.

- Isolation: Electrical isolation to protect the module from noise and ground loops.

- Diagnostics: Built – in self – diagnostic function to monitor the health of the module.

- Power Supply: Usually operates on a specific DC voltage, such as 24 V DC.

- Operating Temperature: 0 – 55 °C for working, – 20 – 85 °C for storage.

- Humidity: Relative humidity ranging from 20% to 80% without condensation.

ABB UAD206A101

3. Advantages and Features

The ABB UAD206A101 offers several notable advantages. Its high – accuracy measurement capabilities ensure that the acquired data is reliable, with a resolution that can distinguish small changes in the input signals. The built – in isolation feature enhances the module’s immunity to electrical noise, reducing the risk of signal interference and improving the overall system stability. The self – diagnostic function allows for quick detection of potential faults, enabling timely maintenance and minimizing downtime. In addition, its compatibility with ABB’s extensive range of control systems makes it easy to integrate into existing automation setups, saving time and effort during installation and configuration.

4. Application Areas and Case Studies

This module is widely applied in various industries, including manufacturing, energy, and water treatment. In a manufacturing plant, for example, the ABB UAD206A101 is used to monitor the temperature and pressure of industrial processes. By accurately measuring these parameters, the control system can adjust the process variables in a timely manner to ensure product quality and production efficiency. In a power plant, it is used to collect data from sensors monitoring the temperature and pressure of steam turbines, providing crucial information for the safe and efficient operation of the turbines.

5. Competitor Comparison

Compared to similar products in the market, the ABB UAD206A101 stands out for its excellent accuracy and reliability. Some competing products may have lower accuracy or poorer isolation performance, which can affect the quality of data acquisition and the stability of the control system. The UAD206A101‘s strong compatibility with ABB’s systems also gives it an edge, as it can seamlessly integrate with other ABB components, while some competitors’ products may require additional adapters or configuration efforts.

ABB UAD206A101

6. Selection Recommendations

When selecting the ABB UAD206A101, consider the following factors. First, ensure that the module’s input types and channels match the requirements of your sensors and control system. Second, check the compatibility with your existing ABB drives and control equipment to ensure seamless integration. Also, consider the environmental conditions where the module will be installed, such as temperature and humidity, to ensure that it can operate reliably. Finally, take into account your budget, but keep in mind that the UAD206A101‘s high performance and reliability can bring long – term benefits to your automation system.

7. Precautions

During installation, make sure to follow the manufacturer’s instructions carefully. Ensure proper grounding to prevent electrical interference and potential damage to the module. When connecting sensors, check the signal range and type to avoid incorrect connections. Regularly check the module’s operating status and perform maintenance as recommended to ensure its long – term reliable operation. Also, keep the installation environment clean and dry to prevent dust and moisture from affecting the module’s performance.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.