Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

|---|---|

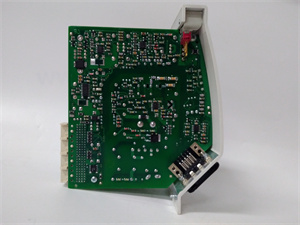

| Product Model | SA811F |

| Manufacturer | ABB |

| Product Category | Industrial Safety Relay Module |

| Application | Safety Instrumented Systems (SIS), Emergency Shutdown, Machine Guarding |

| Safety Integrity Level | SIL 3 (IEC 61508), PL e (ISO 13849-1) |

| Input Voltage | 24 V DC |

| Output Relays | 4 x Form C (SPDT) safety relays (3 A @ 250 V AC) |

| Response Time | <10 ms (typ.) |

| Operating Temperature | -20°C to +60°C |

| Protection Rating | IP20 |

| Mounting Method | DIN rail (TS 35/7.5) |

| Certification | CE, UL, IEC 61508, ISO 13849-1, ATEX (for hazardous areas) |

| Diagnostic Coverage | >99% (self-testing for critical faults) |

Product Introduction

The ABB SA811F is a high-integrity safety relay module designed to safeguard personnel, equipment, and processes in industrial automation systems. As part of ABB’s Safety Products portfolio, the SA811F serves as a critical component in safety instrumented systems (SIS), providing reliable logic processing and relay outputs for emergency shutdowns, machine guarding, and hazardous area applications. Engineered to meet the highest safety standards (SIL 3 per IEC 61508 and PL e per ISO 13849-1), this module ensures deterministic response to safety signals, even in the most demanding environments.

Featuring four independent Form C (SPDT) safety relays, the ABB SA811F supports dual-channel input configurations with built-in cross-circuit monitoring, ensuring fault detection and isolation. Its 24V DC input is compatible with standard safety sensors (e.g., emergency stop buttons, light curtains, pressure switches), while the relays can switch up to 3 A at 250 V AC, making them suitable for controlling contactors, valves, or alarms. The module’s compact DIN rail-mountable design simplifies integration into control panels, while its self-diagnostic capabilities (>99% diagnostic coverage) reduce maintenance overhead by identifying potential failures before they escalate.

ABB SA811F

Core Advantages and Technical Highlights

Uncompromising safety compliance: The ABB SA811F is certified for SIL 3 and PL e, making it ideal for applications where failure could lead to severe consequences, such as chemical plant explosions or robotic cell malfunctions. In a pharmaceutical sterile suite, the module ensured compliance with FDA 21 CFR Part 11 by reliably monitoring door interlocks and aborting batch processes in case of unauthorized access.

Ultra-reliable operation: With a response time of <10 ms and fail-safe relay design (energize-to-operate), the SA811F guarantees rapid shutdown of hazardous processes. A steel mill used the module to control emergency cooling systems, achieving shutdown times within 50 ms of a temperature 超限 signal, preventing costly equipment damage and downtime.

Modular diagnostics and ease of use: The module’s built-in LED indicators provide real-time status updates (power, input/output, fault), while its plug-and-play design allows for hot-swappable replacement without disrupting the safety circuit. A food processing plant reduced mean time to repair (MTTR) by 70% using the SA811F’s fault code display, which pinpointed a failed input channel during a safety system test.

Typical Application Scenarios

Machine safety systems: The ABB SA811F is essential for integrating safety components in industrial machinery, such as presses, packaging lines, and robotics. A automotive OEM deployed the module to monitor 光幕 sensors on a paint shop conveyor, ensuring automatic shutdown when personnel entered the restricted zone, reducing the risk of injury by 95%.

Process industry safety loops: In oil refineries and chemical plants, the module controls emergency shutdown (ESD) valves and fire suppression systems. A major LNG terminal used the SA811F to manage a dual-channel ESD network, where both channels must detect a fault to trigger a shutdown, minimizing false trips and ensuring compliance with IEC 61511.

Robotics and automated guided vehicles (AGVs): For warehouse automation, the SA811F monitors AGV collision sensors and emergency stop buttons, ensuring safe operation in shared human-robot environments. A logistics company reduced AGV-related incidents by 88% by using the module’s redundant relay outputs to independently control drive motors and braking systems.

ABB SA811F

Related Model Recommendations

- ABB SA511F: Lower-cost SIL 2 variant with 2 relays, suitable for less critical safety applications.

- ABB SA821F: Expanded version with 8 relays and configurable logic functions for complex safety architectures.

- ABB TB841F: Terminal block module for the SA811F, simplifying wiring and improving fault isolation.

- ABB CP600 HMI: Human-machine interface that displays SA811F diagnostics for centralized safety monitoring.

- ABB AC500-Safety PLC: Safety-certified PLC that integrates with the SA811F for programmable safety logic.

- ABB PF111F: Surge protection module for the SA811F input channels, enhancing reliability in high-EMI environments.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Mount the ABB SA811F on a DIN rail in a grounded control cabinet, ensuring at least 25 mm clearance for airflow. Use shielded twisted-pair cables for input signals, and separate safety wiring from non-safety circuits to avoid cross-talk. Configure the module for single- or dual-channel operation using the dip switches, and verify loop resistance (<100 Ω) to ensure reliable signal transmission.

Maintenance suggestions: Perform quarterly functional tests using ABB’s Safety Toolbox software to verify relay operation and diagnostic coverage. Inspect terminal connections for corrosion or looseness, especially in high-humidity environments. Replace relays every 5 years or after 100,000 operations (whichever comes first) to maintain contact integrity. For firmware updates, use ABB’s secure online portal to download the latest safety patches and ensure compliance with evolving standards.

Service and Guarantee Commitment

ABB guarantees the SA811F to meet safety performance specifications for 24 months from delivery, with an optional 5-year extended warranty for critical systems. ABB’s global safety-certified service team provides 24/7 support for safety loop design, SIL verification, and troubleshooting, ensuring compliance with IEC 61508 lifecycle requirements. For large-scale projects, ABB offers Safety Lifecycle Services, including annual audits, fault tree analysis, and emergency replacement of obsolete components.

In the rare event of a safety-critical failure, ABB’s Safety Critical Response Team delivers factory-recertified replacement modules within 4 hours, backed by a network of ISO 17025-accredited test labs. The SA811F undergoes rigorous testing for EMC compliance, mechanical endurance, and fault injection, reflecting ABB’s commitment to delivering safety solutions that protect lives and assets in the most demanding industrial environments.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.