Description

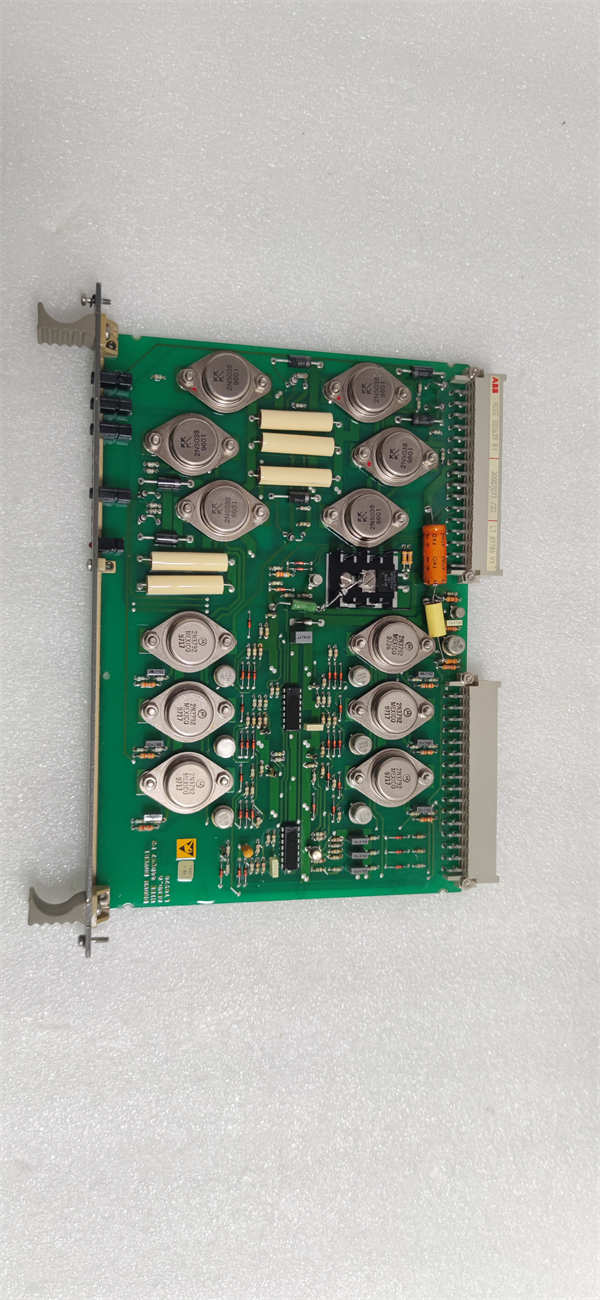

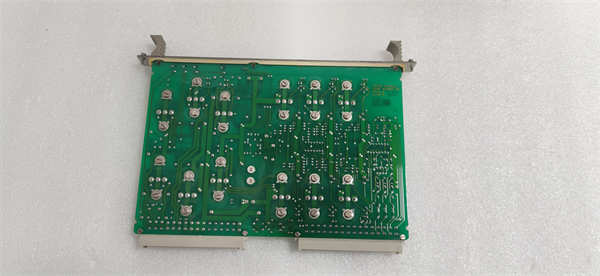

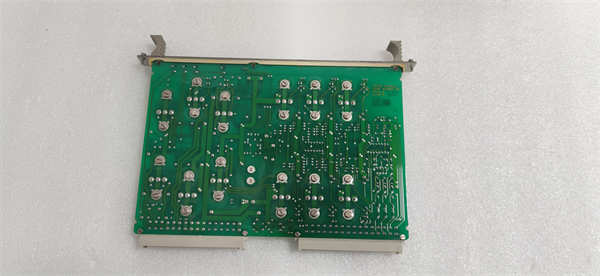

1. Product Description

2. Product Parameters

| Parameter | Specification |

|---|---|

| Module Type | Digital Input Module (16 channels) |

| Voltage Range | 24 V DC ±10% (single-supply operation) |

| Input Signal Type | Dry contacts or NPN/PNP open-collector signals |

| Isolation | Galvanic isolation (250 V AC between channels and system) |

| Filter Time | Adjustable (0.1–32 ms per channel) |

| Communication Interface | Proprietary bus for connection to ABB controllers |

| Operating Temperature | -40°C to +70°C (-40°F to +158°F) |

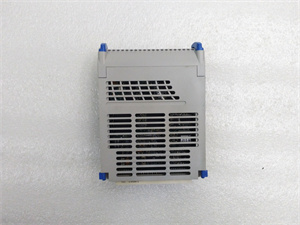

| Dimensions (W×H×D) | 100 mm × 150 mm × 50 mm (3.94″ × 5.91″ × 1.97″) |

| Mounting | DIN rail or panel mountable |

| Certifications | CE, UL, CSA, IEC 61000-6-2 (EMC compliant) |

LT8978bV1

3. Advantages and Features

- Enhanced Reliability: The LT8978bV1’s galvanic isolation and wide temperature range ensure stable operation in challenging environments. In a steel mill application, the module maintained 100% signal accuracy despite ambient temperatures exceeding +60°C and high EMI from heavy machinery.

- Flexible Configuration: Adjustable filter times allow customization for noise reduction. For example, in a packaging line with frequent vibration-induced signal noise, setting a 16 ms filter reduced false triggers by 95%.

- Efficient Diagnostics: Real-time LED indicators for each channel and system communication status enable rapid fault identification. A food processing plant reported a 30% reduction in troubleshooting time after deploying ABB LT8978bV1 due to its intuitive diagnostic feedback.

- Space-Saving Design: With 16 channels in a compact form factor, the module optimizes control cabinet space, supporting dense I/O configurations in modular systems.

4. Application Areas and Application Cases

- Manufacturing: Assembly lines, robotics, and quality control systems.

- Energy: Power plants, substations, and renewable energy facilities.

- Process Industries: Chemical plants, water treatment, and oil & gas production.

5. Competitive Comparison

Compared to generic digital input modules, the ABB LT8978bV1 offers deeper system integration with ABB’s control platforms, eliminating the need for custom drivers or protocol converters. Its extended temperature range and EMI resistance outperform standard modules, which often fail in extreme conditions. While some competitors offer similar channel counts, few match its combination of built-in diagnostics and rugged construction, making it a preferred choice for mission-critical applications.

LT8978bV1

6. Selection Recommendations

- Compatibility: Ensure the module is compatible with your ABB controller (e.g., AC 800M, Freelance) and backplane system.

- Environmental Needs: Prioritize this module for harsh environments (e.g., high heat, dust, or EMI) where standard modules may degrade.

- Signal Noise Requirements: If your application involves noisy signals (e.g., proximity sensors in vibration-heavy machinery), utilize the adjustable filter feature to optimize signal quality.

- Scalability: For future expansions, consider pairing with ABB’s digital output modules (e.g., DO810) to build a complete I/O solution.

7. Precautions

- Installation: Power off the system before installing the module to avoid electrostatic discharge (ESD) damage. Use shielded twisted-pair cables for signal wiring, keeping them separate from power cables.

- Wiring: Follow ABB’s terminal block diagrams to ensure correct polarity and grounding. Verify that field devices match the module’s voltage requirements (24 V DC).

- Maintenance: Regularly inspect LED indicators for abnormal status (e.g., constant red for fault conditions). Clean the module periodically to prevent dust accumulation, especially in high-dust environments.

- Software Configuration: Use ABB’s Control Builder software to enable/disable filter times and assign channel addresses, ensuring proper integration with the control system.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.