Description

Product Overview

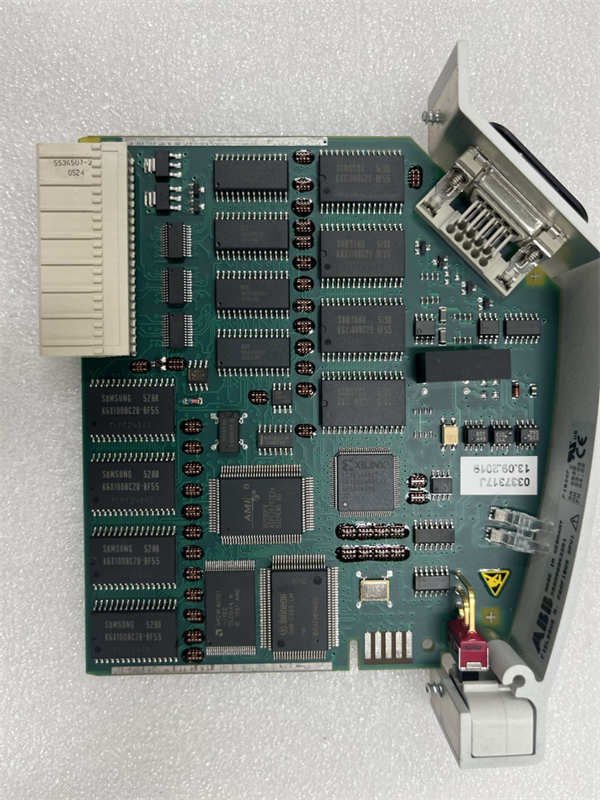

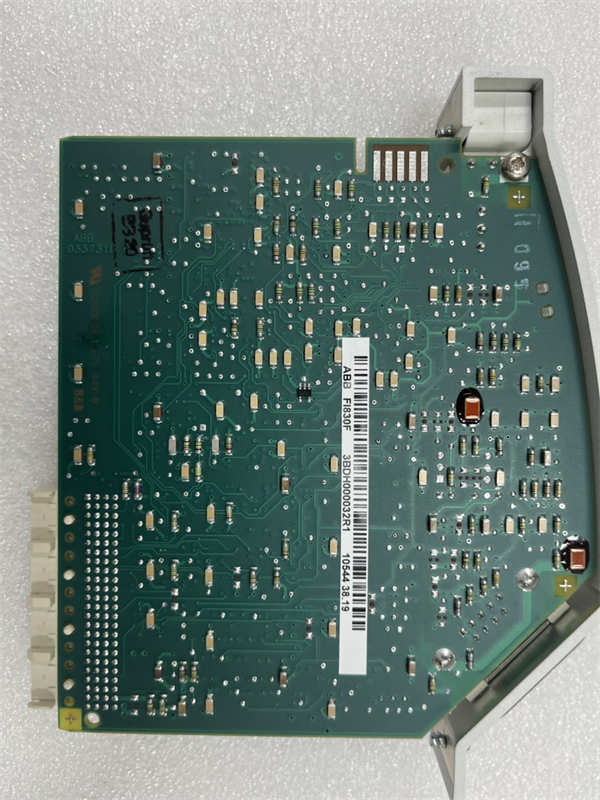

The ABB FI830F is a high-performance frequency input module designed for ABB’s AC 800M distributed control system (DCS), serving as a critical interface for acquiring and processing frequency-based signals from industrial devices. As part of the S800 I/O series, this module is engineered to convert analog frequency signals (e.g., from tachometers, pulse generators, or variable speed drives) into digital data with exceptional accuracy, enabling real-time monitoring and control in applications requiring precise speed, flow, or position feedback. The FI830F features advanced signal conditioning, noise immunity, and diagnostics, ensuring reliable performance in harsh industrial environments such as manufacturing plants, power generation facilities, and process industries.

Featuring 8 isolated frequency input channels, the ABB FI830F supports a wide frequency range (0–50 kHz) and multiple signal types, including voltage (0–10 V) and current (4–20 mA) inputs. Its core functions include high-resolution frequency-to-digital conversion, signal filtering, and fault detection for open circuits or signal loss, ensuring data integrity even in high-electromagnetic-interference (EMI) environments. Positioned as a versatile solution for motion control and process automation, the module integrates seamlessly with ABB’s Control Builder M software, enabling centralized configuration, calibration, and real-time diagnostics to optimize system efficiency. By providing scalable and rugged frequency measurement capabilities, the FI830F plays a pivotal role in enabling precise automation and predictive maintenance across diverse industrial applications.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | FI830F |

| Manufacturer | ABB |

| Product Type | Frequency Input Module (FI) |

| Channel Count | 8 channels |

| Frequency Range | 0–50 kHz (configurable) |

| Signal Types | Voltage (0–10 V), Current (4–20 mA) |

| Resolution | 16-bit (±0.01% accuracy) |

| Isolation | Galvanic isolation (2.5 kV AC) |

| Sampling Rate | 1 ms/channel |

| Communication Interface | Profibus DP, Ethernet/IP (via AC 800M) |

| Power Supply | 24 V DC (from backplane) |

| Operating Temperature | -40°C to +70°C |

| Dimensions (W×H×D) | 45 mm × 100 mm × 110 mm |

| Mounting Method | DIN rail (TS 35) |

| Certification | CE, UL, IEC 61131-2 compliant |

FI830F

Main Features and Advantages

The ABB FI830F distinguishes itself through its precision, reliability, and adaptability to diverse industrial requirements. Its galvanic isolation per channel protects the control system from voltage spikes and ground loops, a critical feature in environments with heavy machinery or unstable power supplies. The module’s software-configurable frequency ranges and signal types eliminate the need for hardware reconfiguration, allowing seamless integration with a wide range of field devices, from motor speed sensors to flow meters.

A key advantage is the FI830F’s real-time diagnostics, which monitor signal integrity, power status, and channel health via LED indicators and Control Builder M. This proactive monitoring reduces mean time to repair (MTTR) by quickly identifying issues such as signal loss or noise interference. The module’s hot-swappable design enables replacement without powering down the system, minimizing downtime in 24/7 production environments.

The FI830F also offers high-speed sampling (1 ms per channel), ensuring accurate capture of fast-changing frequency signals, the speed of rotating machinery in aerospace manufacturing or the flow rate of high-velocity fluids in chemical processing. Its compact form factor optimizes space in control panels, while the rugged enclosure with reinforced connectors withstands vibration, moisture, and extreme temperatures, ensuring reliability in harsh settings.

Application Field

The ABB FI830F is widely deployed in industries requiring precise frequency-based measurements. In manufacturing, it monitors motor speeds in conveyor systems, robotics, and assembly lines, enabling real-time adjustment of production rates to optimize efficiency. For power generation, the module measures turbine RPM, generator frequency, and energy flow in renewable energy systems (e.g., wind farms), ensuring stable grid integration and compliance with power quality standards.

In oil and gas, the FI830F interfaces with flow meters and pressure transducers in pipelines and refineries, providing critical data for process control and leak detection. It also excels in water treatment, where it measures pump speeds and flow rates to optimize water distribution and chemical dosing, ensuring consistent treatment quality. By addressing challenges like signal accuracy, noise immunity, and maintainability, the module helps customers achieve higher process reliability, reduce measurement errors, and enhance safety across diverse applications.

FI830F

Related Products

- ABB AI830F: An analog input module complementary to the FI830F, supporting voltage/current signals for mixed-measurement systems.

- ABB AO810: An analog output module for controlling actuators based on frequency input data from the FI830F.

- ABB AC 800M Controller (PM866AK01): A high-performance controller that processes frequency data from the FI830F to execute control logic.

- ABB TB820 V2: A terminal block module designed for the S800 I/O series, simplifying field wiring for frequency sensors.

- ABB CI858-1 3BSE018137R1: A communication module that enables Ethernet/IP connectivity for the FI830F, supporting remote monitoring in IIoT environments.

- ABB FI820F: A lower-channel variant (4 channels) for smaller-scale applications requiring frequency input capabilities.

Installation and Maintenance

Pre-installation preparation: Mount the ABB FI830F on a DIN rail in a grounded control panel, ensuring proper ventilation and separation from high-power cables. Connect frequency sensors to the module’s terminal blocks using shielded twisted-pair (STP) wiring to minimize EMI, following the signal type (voltage/current) and polarity specified in the manual. Use Control Builder M to configure each channel’s frequency range, signal type, and scaling factors, and assign input addresses within the controller’s I/O map.

Maintenance recommendations: Regularly inspect the module’s LED indicators and diagnostic logs for fault codes (e.g., signal loss, overrange). Test channel accuracy annually using a calibrated frequency generator to verify conversion precision. Clean ventilation slots with compressed air to prevent dust accumulation, and ensure the operating temperature remains within specified limits. In high-vibration environments, check terminal connections for tightness to avoid loose wiring. For hardware faults, replace the module using hot-swappable procedures, ensuring the replacement unit is pre-configured to minimize downtime.

Product Guarantee

ABB stands behind the FI830F with a comprehensive quality assurance program, including rigorous testing for EMC compliance, thermal stability, and measurement accuracy. The module is backed by a standard 2-year warranty, covering defects in materials and workmanship. ABB’s global technical support team provides 24/7 assistance for configuration, troubleshooting, and replacement services, ensuring rapid issue resolution. Customers can access firmware updates, installation guides, and training resources via ABB’s online platforms, reinforcing the company’s commitment to reliable, high-performance industrial automation components. With a focus on precision and durability, the FI830F remains a trusted choice for frequency measurement in critical industrial systems.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.