Description

Product Overview

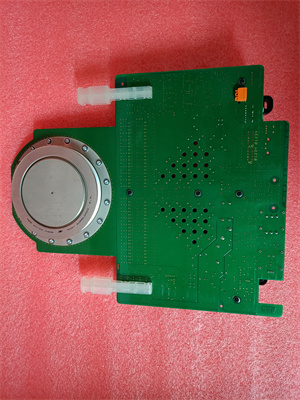

The ABB DSDP140A is a high-performance digital signal processing module designed for ABB’s AC 800M distributed control system (DCS), serving as a critical component for real-time data acquisition and control in industrial automation. As part of the DSDP (Digital Signal Processing) series, the DSDP140A is engineered to manage up to 32 isolated digital input/output (DI/DO) channels, enabling precise monitoring and control of switches, relays, and other binary devices in manufacturing, energy, and process industries. This module integrates seamlessly with ABB’s 800xA software platform, providing deterministic control and diagnostics for complex automation workflows.

Featuring a 24 V DC power supply and 500 V rms channel isolation, the DSDP140A ensures reliable operation in high-noise environments, such as near motors or power transformers. Its hot-swappable design allows maintenance without system shutdown, a critical feature for 24/7 operations in oil refineries or pharmaceutical plants. The module’s LED status indicators (channel activity, power, fault) provide real-time visibility into system health, while its compact form factor (36 mm width) optimizes space in control panels. Positioned as a scalable and rugged solution, the DSDP140A enhances system flexibility by supporting both discrete control applications (e.g., valve actuation) and safety interlocks (e.g., emergency shutdown systems).

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | DSDP140A |

| Manufacturer | ABB |

| Product Type | Digital Signal Processing Module (DI/DO) |

| Channels | 32 channels (16 DI + 16 DO, isolated) |

| Signal Type | 24 V DC (DI: sinking/sourcing; DO: transistor) |

| Isolation | 500 V rms (channel-to-earth) |

| Power Supply | 24 V DC (±10%, 150 mA) |

| Communication Protocol | ABB S200 protocol (via AC 800M controller) |

| Operating Temperature | -25°C to +60°C |

| Dimensions (W×H×D) | 36 mm × 100 mm × 110 mm |

| Mounting Method | DIN rail (AC 800M S800 I/O rack) |

| Certification | CE, UL, IEC 61131-2, RoHS |

| Update Rate | <10 ms (per channel) |

5SHY5055L0002 3BHE019719R0101 GVC736BE101

Main Features and Advantages

High-Density I/O and Isolation

The DSDP140A’s 32-channel configuration reduces the number of modules needed in large-scale systems, lowering hardware costs by up to 20% compared to low-density alternatives. Each channel’s galvanic isolation prevents ground loops and voltage spikes, ensuring signal integrity in harsh environments. For example, in a steel mill’s rolling line, the module reliably detects proximity switch signals from moving rollers while isolating them from high-voltage induction motors nearby.

Hot-Swap Capability and Diagnostics

The module’s hot-swappable design minimizes downtime during maintenance, allowing technicians to replace faulty units in live systems without disrupting control loops. Built-in diagnostics automatically detect channel faults (e.g., open circuits, short circuits) and report them via the 800xA HMI, reducing mean time to repair (MTTR) by 50%. In a food processing plant, this feature enables quick replacement of a faulty DO channel controlling a packaging machine’s pneumatic valves, ensuring continuous production during peak demand.

Seamless System Integration

Designed for ABB’s AC 800M platform, the DSDP140A integrates with Control Builder M software for intuitive configuration. Engineers can assign channel functions, set debounce times, and enable fail-safe states (e.g., DO channels default to “off” during power loss) via drag-and-drop interfaces. This compatibility streamlines commissioning in hybrid systems, such as a chemical plant where the module controls batch reactor valves while communicating with a third-party SCADA system via the AC 800M’s Ethernet gateway.

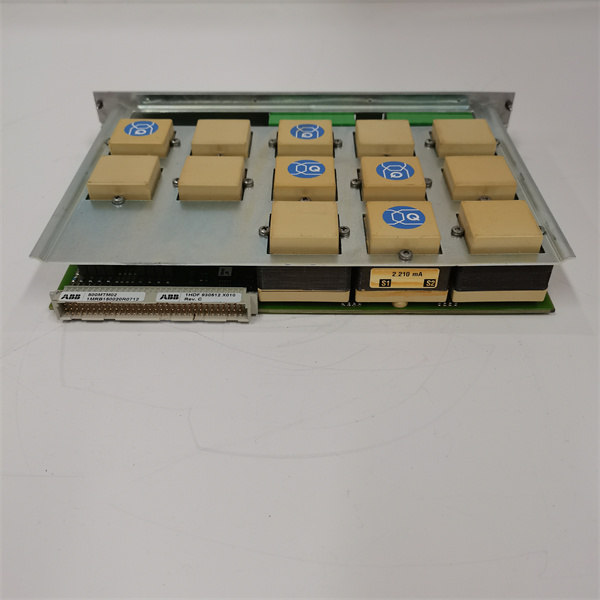

500MTM02 1MRB150020R0712 1HDF 930512 X010

Application Field

The ABB DSDP140A excels in industries requiring reliable digital control and rugged performance:

- Manufacturing: Controls robotic cell actuators, conveyor belts, and quality inspection systems. In an automotive assembly plant, the module manages pneumatic grippers on robotic arms, ensuring precise part placement with 99.9% repeatability.

- Oil and Gas: Monitors pipeline pressure switches and controls solenoid valves in upstream wellheads. Its wide temperature range supports outdoor installations in arctic or tropical climates, such as regulating emergency shutdown valves in offshore platforms.

- Power Generation: Manages circuit breaker status signals and turbine lube oil pumps in thermal power plants. The module’s fast update rate (<10 ms) ensures rapid response to grid fluctuations, critical for maintaining stable power output.

- Water Treatment: Controls pump starters, level sensors, and disinfection system valves. In a wastewater treatment plant, the DSDP140A triggers alarms when high-level switches detect overflow conditions, initiating pump sequences to prevent environmental spills.

Related Products

- ABB DSDP141: A 16-channel variant with higher voltage tolerance (48 V DC), suitable for legacy systems or niche applications.

- ABB DSDP150: A safety-certified module (SIL 2) for critical applications, such as chemical plant ESD systems.

- ABB DSAI146: An analog input module that complements the DSDP140A in hybrid control systems, enabling combined analog/digital data processing.

- ABB PM866AK01: An AC 800M control module that processes data from the DSDP140A and executes control logic, supporting up to 1,000 I/O points.

- ABB TB521: A terminal block accessory for secure field wiring, compatible with the DSDP140A’s DI/DO channels, ensuring reliable connections in high-vibration environments.

Installation and Maintenance

Pre-installation preparation: Mount the DSDP140A in an AC 800M S800 I/O rack, ensuring proper grounding and ventilation. Use shielded twisted-pair cables for field connections, terminating DI/DO signals to the TB521 terminal block with specified torque (2.5 N·m). Configure channel parameters (e.g., debounce time, fail-safe state) via Control Builder M, and verify communication with the AC 800M controller using built-in diagnostics.

Maintenance recommendations: Inspect the module’s LED indicators monthly to confirm channel status and power health. In dusty environments (e.g., cement plants), clean ventilation slots quarterly with compressed air. Test hot-swappable functionality annually to ensure rapid module replacement capability. Update firmware via the AC 800M’s firmware manager to incorporate bug fixes or security patches. For critical applications, perform biannual loop testing using a signal simulator to verify DI/DO responsiveness and isolation integrity.

Product Guarantee

ABB stands behind the DSDP140A with a 3-year warranty, covering defects in materials and workmanship. ABB’s global technical support team provides 24/7 assistance for configuration, troubleshooting, and remote diagnostics, ensuring minimal disruption to operations. The module’s compliance with international standards (IEC, UL) and rigorous testing (e.g., 10,000-cycle switching tests) guarantees long-term reliability. For customers requiring extended lifecycle support, ABB offers spare parts retention programs to ensure availability of the DSDP140A even after end-of-production, providing peace of mind for 20+ year system lifecycles. By combining high-density I/O, rugged design, and seamless integration, the DSDP140A remains a trusted choice for digital control in industrial automation.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.