Description

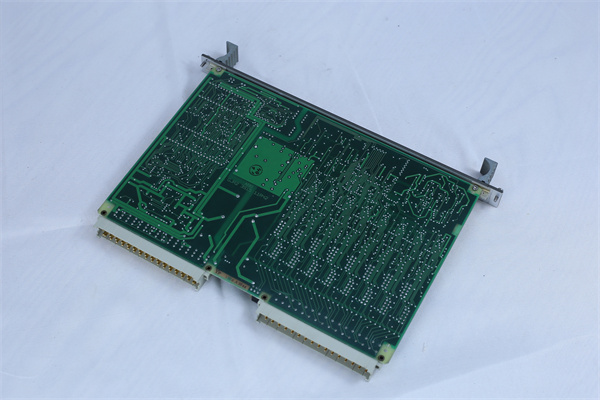

1. Product Description

2. Product Parameters

| Parameter | Details |

|---|---|

| Input Channels | 16 universal channels (isolated) |

| Signal Types | Voltage (±250 V DC), current (±20 mA), resistance (0–2 kΩ) |

| Resolution | 14-bit analog-to-digital conversion |

| Accuracy | ±0.1% of full-scale reading |

| Communication | PROFIBUS DP, Modbus RTU (via gateway), or direct connection to ABB controllers |

| Power Supply | 24 V DC (±10%) |

| Current Consumption | ≤50 mA |

| Operating Temperature | -20°C to +60°C (-4°F to +140°F) |

| Storage Temperature | -40°C to +85°C (-40°F to +185°F) |

| Mounting | DIN-rail mountable (TS 35/7.5 or TS 35/15) |

| Dimensions (W×H×D) | 36 mm × 150 mm × 150 mm |

| Certifications | CE, UL, cUL, EN 61000 (EMC compliant) |

81EU01E-E

3. Advantages and Characteristics

- Multi-Signal Flexibility: The 81EU01E-E eliminates the need for dedicated modules per signal type, reducing inventory costs by up to 30% in diverse sensor environments. For example, in a chemical plant, it simultaneously monitors temperature (RTD inputs), pressure (4–20 mA signals), and valve positions (voltage signals) on a single module.

- High Precision and Noise Immunity: Its isolated channels and advanced filtering technology minimize electromagnetic interference (EMI), ensuring reliable data in noisy industrial environments. The 14-bit resolution supports precise process control, the ±0.1% accuracy critical for applications like pharmaceutical dosing or oil refining.

- Hot-Swap Capability: The module can be replaced without powering down the system, reducing downtime during maintenance. This feature was leveraged in a food processing plant, where a faulty channel was replaced in under 5 minutes during production, avoiding a 2-hour shutdown.

4. Application Fields and Application Cases

- Manufacturing: Machine condition monitoring (vibration sensors, temperature probes).

- Energy: Power plant instrumentation (steam pressure transmitters, flow meters).

- Process Control: Chemical batch processing (level sensors, pH meters).

- Water/Wastewater: Pump status monitoring (current sensing, dry contact inputs).

A major automotive manufacturer integrated the ABB 81EU01E-E into its body shop automation system to monitor 128 signals from robotic welders, conveyor belts, and quality control sensors. The module’s multi-signal support and high-speed scanning (10 ms update rate) enabled real-time detection of welding anomalies, reducing defect rates by 22% and improving overall equipment effectiveness (OEE) by 15%.

5. Competitor Comparison

Compared to similar universal input modules, the ABB 81EU01E-E offers superior channel density (16 channels in a compact 36 mm width) and broader signal type support, eliminating the need for signal conditioners in most applications. Its built-in diagnostics (e.g., channel-level fault reporting) reduce troubleshooting time by 40% compared to non-intelligent modules, while ABB’s ecosystem integration (e.g., pre-configured templates in Control Builder M) cuts engineering time by 25%.

81EU01E-E

6. Selection Suggestions

- Signal Requirements: Confirm the module supports your sensor’s output type (e.g., mA for transmitters, ohms for RTDs).

- System Compatibility: Ensure compatibility with your controller (e.g., ABB AC 800M, 800xA) and communication protocol (PROFIBUS DP preferred for ABB systems).

- Environmental Needs: For outdoor or high-vibration sites, pair with ABB’s IP67-rated enclosures to meet harsh environment requirements.

- Scalability: Plan for future expansions by leaving 20–30% spare channels, as the module supports up to 128 I/O modules per controller.

7. Precautions

- Wiring: Use shielded twisted-pair cables for analog signals and separate power/control wiring to minimize EMI. Follow ABB’s guidelines for terminal block torque (1.5 N·m).

- Configuration: Calibrate the module using ABB’s Control Builder software to match sensor ranges, and enable channel diagnostics for early fault detection.

- Safety Compliance: For SIL-rated applications, ensure the module is part of a certified safety loop and follow ABB’s functional safety guidelines.

- Maintenance: Regularly inspect for loose connections or corrosion, especially in humid environments. Schedule annual calibration checks for critical channels.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.