Description

Product Overview

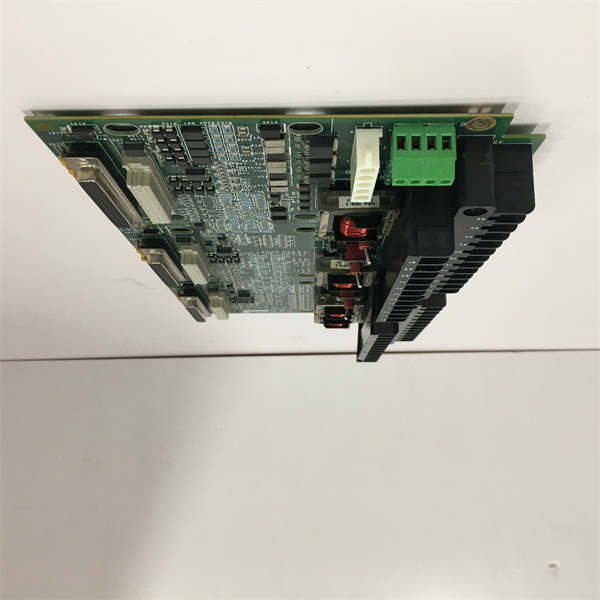

The GE 760 – P1 – G1 – S1 – LO – A20 – R – E is a remarkable low – voltage feeder distribution management system that forms an integral part of the esteemed 760 feeder management relay systems by GE Multilin. This model is engineered to offer comprehensive management, protection, and control solutions for distribution feeders, playing a crucial role in maintaining the reliability and efficiency of power distribution networks.

Within industrial and commercial power systems, the 760 – P1 – G1 – S1 – LO – A20 – R – E acts as a vigilant guardian. It constantly monitors electrical parameters such as current and voltage, ensuring that the power supply to various loads remains stable. By accurately detecting any anomalies or potential faults, it can take prompt actions to prevent disruptions, thus minimizing downtime and safeguarding the integrity of the overall power distribution infrastructure.

Technical Specifications

|

Parameter Name

|

Parameter Value

|

|

Product Model

|

760 – P1 – G1 – S1 – LO – A20 – R – E

|

|

Manufacturer

|

GE Multilin

|

|

Series

|

750 / 760 feeder management relay

|

|

Control Power

|

25 va nominal, 35 va max

|

|

Insulation Voltage

|

300 V

|

|

Overvoltage Category

|

II

|

|

Pollution Degree

|

II

|

|

Communications Protocol

|

Modbus RTU or DNP 3.0

|

|

Data Logging Storage

|

2 to 16 events with 2048 to 256 samples of data respectively

|

|

Waveform Capture Sample Rate

|

16 per cycle

|

|

Current Inputs

|

1A phase current inputs, one 1A sensitive ground current input, 1A zero – sequence current inputs

|

|

Control Power Voltage

|

20 – 60 V DC or 20 – 48 V AC at 48 – 62 Hz

|

|

Analog Outputs

|

Eight 4 – 20 mA analog outputs

|

|

Breaker Indication

|

Red LED for breaker closed indication

|

Main Features and Advantages

Precise Monitoring and Protection

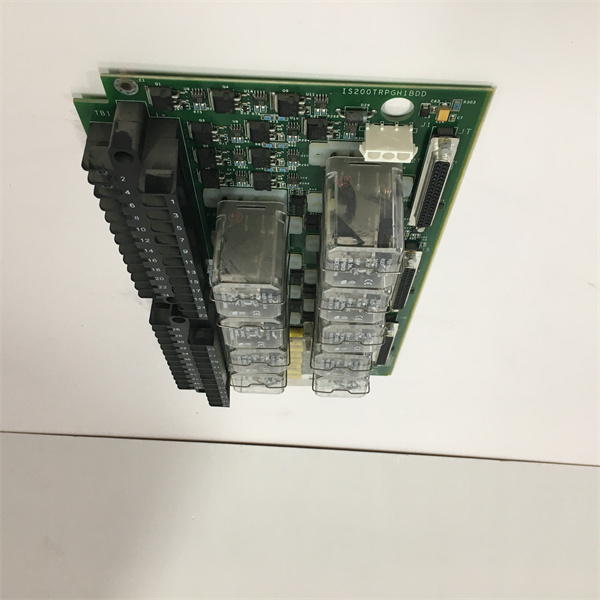

Equipped with 1A phase current inputs, a 1A sensitive ground current input, and 1A zero – sequence current inputs, the GE 760 – P1 – G1 – S1 – LO – A20 – R – E can precisely monitor electrical currents. This allows it to quickly detect overcurrents, ground faults, and other abnormal conditions. Once a fault is detected, it can take immediate protective actions, such as tripping the circuit breaker, to prevent damage to equipment and ensure the safety of the power system.

Versatile Control Power Options

Featuring control power options of 20 – 60 V DC or 20 – 48 V AC at 48 – 62 Hz, this model offers flexibility in power supply. It can adapt to different power source configurations in various industrial and commercial settings, making it easier to integrate into existing power systems without the need for complex power conversion setups.

Multiple Analog Outputs

The eight 4 – 20 mA analog outputs enhance the relay’s functionality. These outputs can be used to interface with other control devices or monitoring systems. For example, they can be connected to analog input modules of a programmable logic controller (PLC) or to analog meters for real – time display of electrical parameters. This enables seamless integration with a wide range of automation and monitoring systems, providing greater control and visibility over the power distribution process.

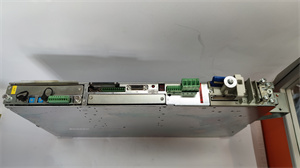

User – Friendly Interface

On the front of the 760 – P1 – G1 – S1 – LO – A20 – R – E is a user – friendly front panel interface. It includes LED status indicators that clearly show potential alarm and status information, allowing operators to quickly identify any issues. The control keys are designed to be intuitive, making it easy to select the appropriate messaging to display measured values and enter setpoints. The liquid crystal display provides clear visual feedback, enhancing the overall usability of the device.

Efficient Data Logging and Communication

With the ability to store 2 to 16 events along with 2048 to 256 samples of data respectively, it can effectively log important electrical events. This data can be used for historical analysis, troubleshooting, and performance evaluation. Additionally, its support for Modbus RTU or DNP 3.0 communication protocols enables seamless communication with other devices in the network. It can transmit data to a central control station or receive commands from a supervisory system, facilitating remote monitoring and control of the feeder management system.

VMICPCI-7632-03310 IS215UCCAH3A 350-657362-003310J

Application Field

Industrial Manufacturing

In industrial manufacturing plants, a stable power supply is crucial for continuous production. The GE 760 – P1 – G1 – S1 – LO – A20 – R – E is used to protect and control the power distribution feeders that supply power to various manufacturing equipment. For instance, in a large – scale automotive manufacturing plant, it can safeguard the power supply to robotic arms, conveyor belts, and other machinery. By detecting and preventing electrical faults, it helps to avoid production disruptions, ensuring smooth and efficient manufacturing processes.

Commercial Buildings

Commercial buildings, such as shopping malls, offices, and hospitals, rely on a reliable power distribution system. The 760 – P1 – G1 – S1 – LO – A20 – R – E can be installed in the electrical switchgear of these buildings to manage and protect the feeders. In a large shopping mall, it can monitor the power supply to different zones, including retail areas, food courts, and parking lots. If a fault occurs, it can quickly isolate the affected area, minimizing the impact on customers and tenants while ensuring the safety of the electrical system.

Power Distribution Networks

At the utility level, in power distribution networks, the GE 760 – P1 – G1 – S1 – LO – A20 – R – E is an essential component. It can be deployed in distribution substations to protect and control the feeders that distribute power to end – users. By accurately monitoring and controlling the power flow, it helps to optimize the performance of the distribution network, reduce power losses, and enhance the overall reliability of the power supply.

Related Products

- GE 760 – P1 – G1 – S1 – LO – A1 – R – E: This model is also part of the 760 feeder management relay series. It likely has similar basic functions to the 760 – P1 – G1 – S1 – LO – A20 – R – E, but may differ in certain aspects such as the number of analog outputs or specific input capabilities. It could be a more cost – effective option for applications with less demanding requirements.

- GE 750 series: The 750 series by GE Multilin is related to the 760 series. While the 760 series, including the 760 – P1 – G1 – S1 – LO – A20 – R – E, is more focused on feeder management in certain voltage ranges and applications, the 750 series may have different features or target different market segments within the power management domain.

- GE SR three – inch collar: This is an accessory that can be used with the 760 – P1 – G1 – S1 – LO – A20 – R – E. The SR three – inch collar is designed to enhance the installation or functionality of the relay in some way, perhaps providing additional support or protection during the installation process.

- GE 1A and 5A phase CTS: These current transformers (CTS) are related products. They can be used in conjunction with the 760 – P1 – G1 – S1 – LO – A20 – R – E to accurately measure the current in the power system. The 1A and 5A phase CTS are selected based on the specific current levels in the application, ensuring accurate current monitoring for the relay’s protection and control functions.

- GE demo metal carry case: A carry case designed for demonstration or transportation purposes related to the 760 – P1 – G1 – S1 – LO – A20 – R – E. It can be used to safely store and transport the relay during exhibitions, training sessions, or when moving the device between different testing or installation locations.

Installation and Maintenance

Pre – installation preparation: Before installing the GE 760 – P1 – G1 – S1 – LO – A20 – R – E, ensure that the installation environment meets the specified requirements. The area should be clean, dry, and free from excessive dust and electromagnetic interference. Verify that the power supply voltage is within the range of 20 – 60 V DC or 20 – 48 V AC at 48 – 62 Hz. Use the shortest practical path to connect the ground bus, and a braided, copper, bonding cable with shielding, such as a Belden catalog 8660 (with a minimum of 96 strands of 34 AWG), should be used for grounding. Check the compatibility of the relay with other components in the power system, such as current transformers and circuit breakers.

Maintenance recommendations: Regularly inspect the 760 – P1 – G1 – S1 – LO – A20 – R – E for any signs of physical damage, such as cracks in the casing or loose connections. Monitor the LED status indicators to quickly identify any abnormal conditions. Clean the relay periodically to remove dust and debris that could affect its performance. Check the accuracy of the current and voltage measurements by comparing them with known reference values. Update the firmware of the relay when new versions are available to ensure it has the latest features and security patches. In case of any faults, refer to the detailed user manual provided by GE for troubleshooting steps.

Product Guarantee

General Electric offers a comprehensive product guarantee for the GE 760 – P1 – G1 – S1 – LO – A20 – R – E. The product undergoes strict quality control during manufacturing to meet the highest industry standards. GE provides a standard warranty period, during which any defects in materials or workmanship will be rectified free of charge. Their technical support team is available to assist customers with installation, configuration, and any technical issues that may arise during the product’s lifespan. Whether it’s a query about the relay’s operation, communication settings, or troubleshooting a fault, GE’s experts are committed to ensuring that the 760 – P1 – G1 – S1 – LO – A20 – R – E operates smoothly, providing customers with confidence in their investment in power distribution management solutions.