Description

Product Overview

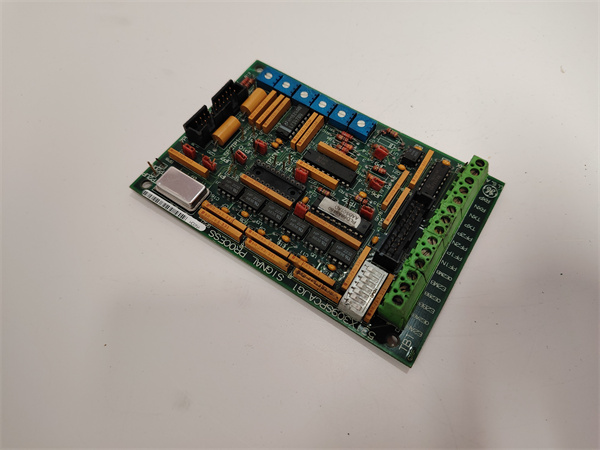

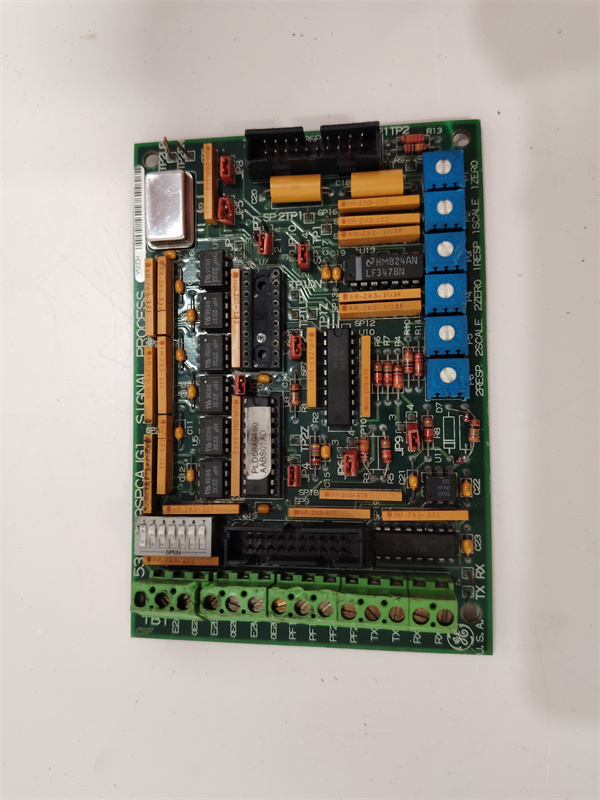

The GE 531X309SPCAJG1 is a high – performance signal processing board meticulously designed by General Electric for industrial automation systems. As part of the esteemed 531X series, this board is a cornerstone for accurate and efficient signal handling within various industrial setups.

Functionally, the GE 531X309SPCAJG1 is adept at processing a diverse range of signals, including analog, digital, voltage, current, and frequency signals. This wide – ranging input compatibility makes it suitable for applications across multiple industries. It plays a crucial role in converting and conditioning signals, ensuring they are in a format suitable for downstream control and monitoring systems. In the context of industrial control, it serves as a key component in systems such as the DC2000 digital adjustable speed drive, where it enables seamless communication and control. By accurately processing signals from sensors, encoders, and tachometers, it provides vital speed feedback to the drive’s control board, contributing to the overall precision and stability of the industrial process.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 531X309SPCAJG1 |

| Manufacturer | General Electric |

| Product Type | Signal Processing Board |

| Series | 531X |

| Input Signal Types | Analog, Digital, Voltage, Current, Frequency |

| Output Interface | Compatible with downstream control systems |

| Processing Speed | High – speed for real – time applications |

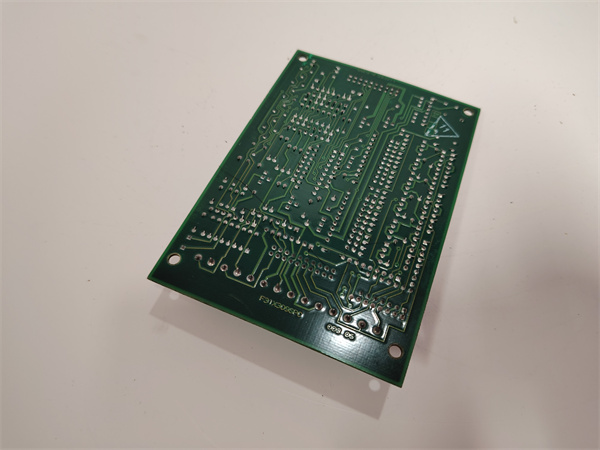

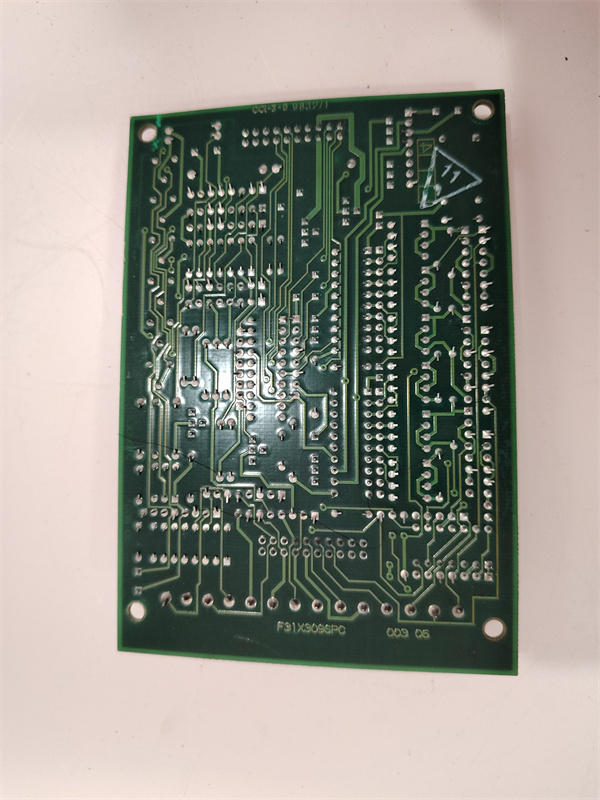

| Mounting Style | Through – hole |

| PCB Type | Double – sided |

| Item Height | 1 inch |

| Item Length | 5 inches |

| Item Width | 3.5 inches |

| Country of Origin | USA |

| Communication Protocols | RS – 422 (for serial signal processing) |

531X309SPCAJG1

Main Features and Advantages

High – Precision Signal Processing

The GE 531X309SPCAJG1 offers exceptional precision in signal processing. It can accurately convert three current reference signals and a voltage level signal into voltage reference signals, which are then transmitted to the drive’s control board for command execution. This high – level accuracy is crucial for applications where precise control is required, such as in high – speed manufacturing processes or sensitive industrial monitoring systems.

Versatile Signal Input Compatibility

With the ability to handle multiple signal types, including analog, digital, voltage, current, and frequency signals, the board is highly versatile. This means it can be integrated into a wide variety of industrial systems without the need for extensive signal conversion or additional hardware. For example, in a complex industrial plant with a mix of different sensors and actuators, the GE 531X309SPCAJG1 can easily interface with all of them, simplifying the overall system design.

Configurable Settings

Featuring configurable switches, jumpers, and potentiometers, users can fine – tune the board according to their specific application requirements. Settings such as signal filtering and gain adjustment can be freely configured, allowing for optimal performance in different industrial scenarios. This flexibility ensures that the GE 531X309SPCAJG1 can adapt to changing process conditions or new application needs over time.

Reliable Performance

Built with high – quality components, the GE 531X309SPCAJG1 is designed to operate reliably in harsh industrial environments. It has been rigorously tested to withstand factors such as temperature variations, electrical interference, and mechanical vibrations. This reliability reduces the risk of system failures and unplanned downtime, ultimately saving costs for industrial operators.

Application Field

Industrial Automation in Manufacturing

In manufacturing plants, the GE 531X309SPCAJG1 is used in production lines for seamless control of machinery. It processes signals from sensors placed on conveyor belts, robotic arms, and other equipment. For instance, it can receive speed and position signals from encoders on robotic arms and convert them into control signals for the arm’s motors, ensuring precise and efficient movement during the manufacturing process.

Power Generation and Distribution

In power plants, whether they are traditional thermal plants or renewable energy facilities like wind farms, this signal processing board plays a vital role. In a wind turbine, it processes signals from sensors that measure wind speed, blade pitch, and generator speed. These processed signals are then used to control the turbine’s operation, such as adjusting the blade pitch to optimize energy capture or controlling the generator’s excitation for stable power output.

Oil and Gas Industry

Within the oil and gas sector, the GE 531X309SPCAJG1 is deployed in refineries and pipelines. In a refinery, it can process signals from flow meters, pressure sensors, and temperature sensors located throughout the facility. These processed signals are used to control pumps, valves, and other equipment, ensuring the safe and efficient operation of the refinery processes. In pipeline systems, it helps in monitoring and controlling the flow of oil and gas by processing signals from various sensors along the pipeline.

531X309SPCAJG1

Related Products

- GE 531X304IBDASG1: A drive card from GE, likely used in the same industrial control systems as the GE 531X309SPCAJG1. While the GE 531X309SPCAJG1 focuses on signal processing, the 531X304IBDASG1 is more centered around driving and controlling components, and they may work in tandem to ensure overall system functionality.

- GE DC2000 Digital Adjustable Speed Drive: The GE 531X309SPCAJG1 is specifically designed to interface with this drive system. It provides crucial signal processing functions for the DC2000 drive, enabling accurate speed control and operation.

- GE AC2000 System Components: These components can be integrated with the GE 531X309SPCAJG1 in industrial setups. The board may process signals related to the operation of AC2000 system components, such as motors or other electrical equipment, to ensure smooth system operation.

- GE Sensor Modules: These sensors are the source of the signals that the GE 531X309SPCAJG1 processes. Different types of sensors, like temperature sensors, pressure sensors, and position sensors, send raw data to the signal processing board, which then converts and conditions these signals for further use in the industrial control system.

- GE Control Boards: The processed signals from the GE 531X309SPCAJG1 are sent to these control boards. The control boards use these signals to make decisions and control the operation of various industrial equipment, highlighting the board’s role as an essential link in the overall control chain.

Installation and Maintenance

Pre – installation preparation: Before installing the GE 531X309SPCAJG1, ensure that the power to the industrial control system is turned off to prevent electrical hazards. Thoroughly inspect the board for any visible signs of damage during transit, such as bent pins or scratches on the circuit board. Verify that the mounting location has the appropriate dimensions and electrical connections to accommodate the through – hole mounting style of the board. Familiarize yourself with the wiring diagram and installation manual provided by GE, and make sure all the necessary tools, such as soldering irons and screwdrivers, are at hand.

Maintenance recommendations: Regularly clean the GE 531X309SPCAJG1 to remove dust and debris, as these can accumulate over time and affect the board’s performance, especially in terms of heat dissipation. Periodically check the configurable settings to ensure they have not been accidentally changed and still align with the requirements of the industrial process. Monitor the board’s operation by observing the performance of the equipment it controls. If there are any sudden changes in the operation of motors or other connected devices, it could indicate a problem with the signal processing board. In such cases, perform a diagnostic check, which may involve testing the input and output signals using appropriate testing equipment. Keep spare parts, such as resistors and capacitors, on hand to quickly replace any that may fail.

Maintenance recommendations: Regularly clean the GE 531X309SPCAJG1 to remove dust and debris, as these can accumulate over time and affect the board’s performance, especially in terms of heat dissipation. Periodically check the configurable settings to ensure they have not been accidentally changed and still align with the requirements of the industrial process. Monitor the board’s operation by observing the performance of the equipment it controls. If there are any sudden changes in the operation of motors or other connected devices, it could indicate a problem with the signal processing board. In such cases, perform a diagnostic check, which may involve testing the input and output signals using appropriate testing equipment. Keep spare parts, such as resistors and capacitors, on hand to quickly replace any that may fail.

Product Guarantee

General Electric stands firmly behind the quality of the GE 531X309SPCAJG1. The product comes with a comprehensive quality assurance program. GE guarantees that the board is free from manufacturing defects for a specified period. In case of any defects during this warranty period, GE will provide repair or replacement services at no additional cost to the customer. Their global network of technical support teams is available around the clock to offer prompt assistance for installation guidance, troubleshooting, and any other technical issues. This reflects GE’s confidence in the reliability and performance of the GE 531X309SPCAJG1, ensuring customers can rely on it for their critical industrial applications.