Description

Product Overview

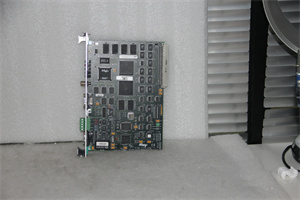

The GE 5136 – PFB – VME is a high – performance VME bus interface module, purpose – built for industrial control systems. As a key component within the industrial automation landscape, it enables seamless and efficient communication between various elements in a control setup. This module is designed to be a reliable bridge, ensuring data flows smoothly among different devices, which is crucial for the overall operation of complex industrial processes.

Operating within the VME bus framework, the GE 5136 – PFB – VME supports multiple communication functions. It can function as a DP slave, a DP master, and is also capable of sending and receiving FDL (Layer 2) messages, with the ability to operate in all these modes simultaneously. This versatility makes it adaptable to different network topologies and control requirements in industrial settings. Whether it’s in a manufacturing plant where real – time control of machinery is essential or in a process control facility managing chemical reactions, the 5136 – PFB – VME plays a vital role in maintaining system integrity and performance.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 5136 – PFB – VME |

| Manufacturer | GE |

| Product Type | VME Bus Interface Module |

| Compatibility | Compatible with VME bus systems |

| Data Rate | Up to 100 Mbps |

| Operating Temperature Range | – 40 °C to + 85 °C |

| Power Supply | 5 V DC |

| Dimensions | 16.5 x 10.2 x 7.6 cm |

| Weight | 0.5 kg |

| ProfiBus Baud Rates Supported | 9.6K, 19.2K, 93.75K, 187.5K, 500K, 750K, 1.5M, 3M, 6M, 12M |

| Processor | On – board Intel i960 |

| Local RAM | 512 Kbytes |

| Shared RAM | 256 Kbytes (linear or paged mode) |

| Address Access | 8 – bit access in short address space; 8 – bit and 16 – bit in standard address space |

| Response to Address Codes | Can respond to 3Dh, 39h, 2Dh, 29h |

5136-PFB-VME

Main Features and Advantages

High – Speed Data Transmission

With a data rate of up to 100 Mbps, the GE 5136 – PFB – VME ensures rapid data transfer between components in the industrial control system. This high – speed communication is essential for applications where real – time control and quick response times are critical, such as in high – speed manufacturing lines or precision process control. It reduces latency, allowing for more efficient operation and better synchronization of devices.

Wide Operating Temperature Range

The module can operate in temperatures ranging from – 40 °C to + 85 °C. This wide temperature tolerance makes it suitable for use in various industrial environments, from cold storage facilities to hot industrial plants. It can withstand extreme conditions without compromising performance, ensuring continuous and reliable operation.

Multiple Communication Modes

As mentioned, it can function as a DP slave, DP master, and handle FDL message transfer simultaneously. This flexibility enables it to be integrated into different types of Profibus networks. For example, in a large – scale industrial setup with multiple levels of control, it can act as a master to some devices and a slave to others, facilitating seamless data exchange across the entire network.

Robust Hardware Configuration

Equipped with an on – board Intel i960 processor and 512 Kbytes of local RAM, the 5136 – PFB – VME has the processing power to handle complex communication protocols and data formatting tasks. The additional 256 Kbytes of shared RAM, which can be configured in linear or paged mode, further enhances its data handling capabilities, ensuring smooth interaction between the interface card and the host application software.

Application Field

Manufacturing Industry

In manufacturing plants, the GE 5136 – PFB – VME is used to control production lines. It can communicate with programmable logic controllers (PLCs), sensors, and actuators. For instance, in an automotive assembly line, it can manage the communication between the PLC controlling the robotic arms and the sensors detecting the position of car parts. This ensures precise and coordinated movement of the robotic arms, improving production efficiency and product quality.

Process Control

In industries such as chemical and oil – and – gas, process control is of utmost importance. The 5136 – PFB – VME can be used to connect different control devices in a process control system. It can transfer data between the central control unit and field devices like valves and pumps. In a chemical plant, it can ensure that the control signals for adjusting the flow rate of chemicals are accurately transmitted, maintaining the stability of the chemical reactions.

Power Generation

In power generation facilities, whether it’s a thermal power plant or a wind farm, the GE 5136 – PFB – VME plays a role in controlling and monitoring operations. In a thermal power plant, it can communicate with the control systems of turbines and generators, ensuring proper power generation and distribution. In a wind farm, it can manage the communication between the wind turbine control units and the central monitoring station, enabling efficient energy production.

5136-PFB-VME

Related Products

GE IC697BEM731: A Genius network card. While the 5136 – PFB – VME focuses on VME bus and Profibus communication, the IC697BEM731 is used for Genius network connectivity. In a GE 90 – 70 PLC system, they can work together to expand the overall communication capabilities, with the IC697BEM731 handling Genius network tasks and the 5136 – PFB – VME dealing with Profibus – related communication.

GE IC697CM M742: An Ethernet network card. This card is responsible for Ethernet – based communication. In industrial control systems, it can complement the 5136 – PFB – VME. For example, the 5136 – PFB – VME can handle internal Profibus communication within the plant floor devices, and the IC697CM M742 can be used to connect the control system to external networks or higher – level management systems via Ethernet.

GE IC697CPX782: A CPU module. The CPU module is the brain of the PLC system. The 5136 – PFB – VME interfaces with the IC697CPX782, receiving commands from the CPU and transmitting data back. The CPU processes the data received through the 5136 – PFB – VME from other devices in the network and makes decisions for controlling the industrial process.

GE IC697PW R711: A power supply module. This module provides the necessary electrical power for components like the 5136 – PFB – VME to operate. A stable power supply from the IC697PW R711 is crucial for the reliable functioning of the 5136 – PFB – VME, ensuring uninterrupted communication and operation in the industrial control system.

GE FBM201: An 8 – channel 0 – 20mA analog input module. In a comprehensive industrial control system, the 5136 – PFB – VME can communicate with modules like the FBM201. The FBM201 collects analog input data from sensors, and the 5136 – PFB – VME can then transfer this data to other parts of the control system for further processing and decision – making.

GE IC697CM M742: An Ethernet network card. This card is responsible for Ethernet – based communication. In industrial control systems, it can complement the 5136 – PFB – VME. For example, the 5136 – PFB – VME can handle internal Profibus communication within the plant floor devices, and the IC697CM M742 can be used to connect the control system to external networks or higher – level management systems via Ethernet.

GE IC697CPX782: A CPU module. The CPU module is the brain of the PLC system. The 5136 – PFB – VME interfaces with the IC697CPX782, receiving commands from the CPU and transmitting data back. The CPU processes the data received through the 5136 – PFB – VME from other devices in the network and makes decisions for controlling the industrial process.

GE IC697PW R711: A power supply module. This module provides the necessary electrical power for components like the 5136 – PFB – VME to operate. A stable power supply from the IC697PW R711 is crucial for the reliable functioning of the 5136 – PFB – VME, ensuring uninterrupted communication and operation in the industrial control system.

GE FBM201: An 8 – channel 0 – 20mA analog input module. In a comprehensive industrial control system, the 5136 – PFB – VME can communicate with modules like the FBM201. The FBM201 collects analog input data from sensors, and the 5136 – PFB – VME can then transfer this data to other parts of the control system for further processing and decision – making.

Installation and Maintenance

Pre – installation preparation: Before installing the GE 5136 – PFB – VME, ensure that the power to the industrial control system is turned off. Check the VME bus slot where it will be installed to make sure it is clean and free of debris. Verify that the slot has the correct mechanical and electrical specifications to accommodate the module. Set the short I/O address using the appropriate dip switches on the module. The 5136 – PFB – VME occupies a 1K – byte short address interval on the VME bus, and the starting address of this memory area is set by the first 6 positions of dip switch S1. Also, ensure that the module is compatible with other components in the system, especially in terms of communication protocols and data transfer requirements.

Maintenance recommendations: Regularly monitor the 5136 – PFB – VME for any signs of overheating, such as unusual warmth or discoloration of the module. Check for any loose connections, as these can disrupt communication. Periodically update the module’s firmware to the latest version to ensure optimal performance and compatibility with other system components. If there are any communication errors, refer to the product manual for troubleshooting steps. In case of hardware failures, contact GE’s technical support for repair or replacement options. Also, keep the module clean from dust and dirt, as these can affect its electrical performance over time.

Product Guarantee

GE stands firmly behind the quality of the GE 5136 – PFB – VME. The module undergoes rigorous testing during the manufacturing process to ensure it meets high – industry standards. In terms of after – sales service, GE offers comprehensive technical support. If the product experiences any quality – related issues within the warranty period, GE will provide repair or replacement services free of charge. Their team of experts is available to assist with installation, configuration, and any operational problems. This commitment reflects GE’s confidence in the product, giving customers peace of mind when integrating the 5136 – PFB – VME into their industrial control systems.