Description

Product Overview

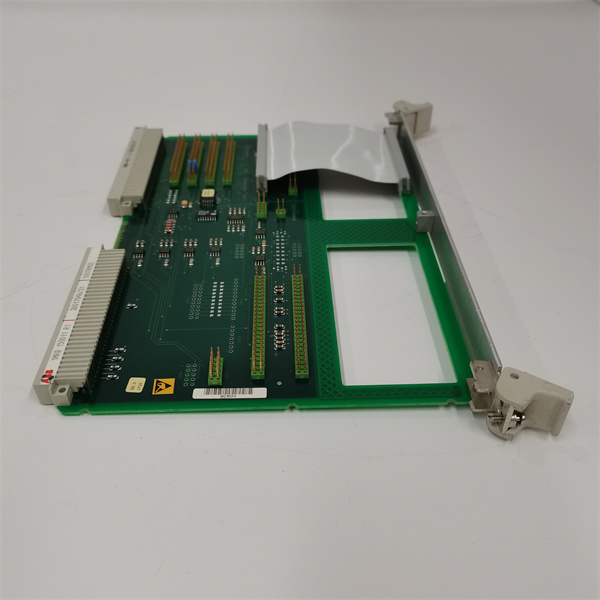

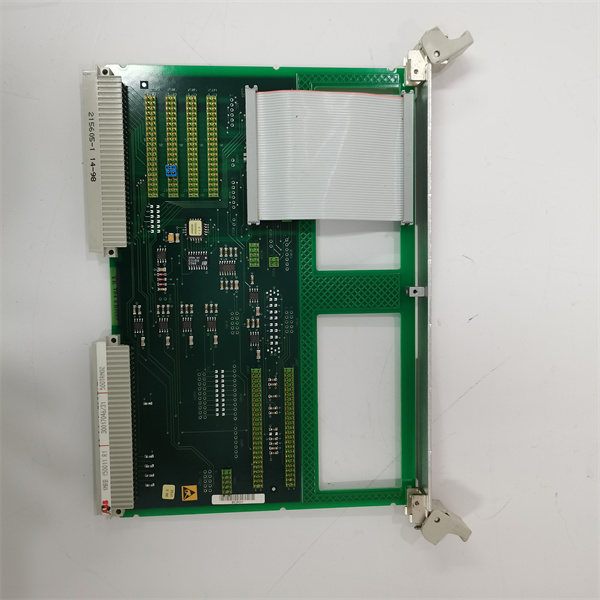

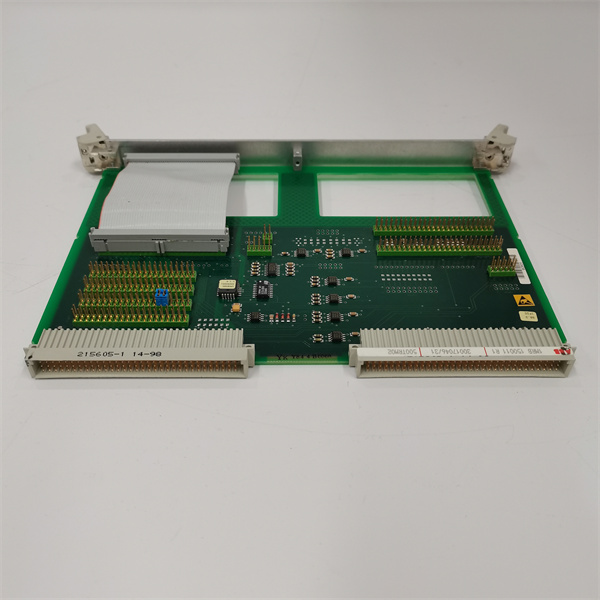

The ABB 500TRM02 1MRB150011R1 is a high-precision motor thermal monitoring and protection module designed for ABB’s industrial motor control systems. As a critical component of the Motor Control and Protection (MCP) portfolio, this module serves as an intelligent interface between motors and distributed control systems (DCS), enabling real-time thermal analysis and fault prevention. The 500TRM02 1MRB150011R1 is engineered to monitor stator and bearing temperatures via PTC/NTC sensors, calculate winding thermal models, and trigger protective actions to prevent motor burnout in manufacturing, energy, and process industries.

Part of the 1MRB1500xx series, the 500TRM02 1MRB150011R1 integrates seamlessly with ABB’s AC 500 PLC and 800xA software, providing detailed diagnostics such as temperature trends, overload margins, and insulation degradation warnings. Its compact design (125 mm × 100 mm × 85 mm) and DIN rail mounting make it suitable for retrofitting the existing control panels, while the 1MRB150011R1 firmware variant enhances compatibility with high-efficiency IE4 motors. Positioned as a proactive maintenance solution, this module reduces unplanned downtime by up to 40% through predictive analytics, ensuring optimal motor health and operational continuity.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 500TRM02 1MRB150011R1 |

| Manufacturer | ABB |

| Product Type | Motor Thermal Monitoring Module |

| Sensor Type | PTC thermistors, NTC sensors, RTDs (Pt100) |

| Channels | 6 thermal sensor inputs (3-phase stator + 3 bearing) |

| Thermal Model | I²t-based winding temperature calculation |

| Protection Functions | Overheat alarm/trip, thermal overload, phase unbalance |

| Communication Protocols | Modbus RTU, Profibus DP, Ethernet/IP |

| Power Supply | 24 V DC (±10%, 50 mA) |

| Operating Temperature | -25°C to +60°C |

| Dimensions (W×H×D) | 125 mm × 100 mm × 85 mm |

| Mounting Method | DIN rail (AC 500/MCP panels) |

| Certification | CE, UL, IEC 60947-4-1, RoHS |

500TRM02 1MRB150011R1

Main Features and Advantages

Advanced Thermal Modeling

The 500TRM02 1MRB150011R1 uses adaptive I²t algorithms to simulate motor winding temperatures in real time, even without direct sensor contact. This feature is critical in applications like wastewater pumps, where submerged motors are inaccessible for physical sensor installation. The module’s thermal memory function stores historical temperature data, enabling trend analysis to identify gradual insulation degradation—a common precursor to motor failure in paper mills or steel plants.

Multi-Sensor Compatibility

Supporting PTC, NTC, and RTD sensors, the module accommodates diverse motor designs and legacy systems. For example, in a pharmaceutical plant, it can monitor PTC sensors in explosion-proof motors while simultaneously tracking RTDs in gearbox bearings, consolidating data into a single interface. The 1MRB150011R1 firmware includes auto-calibration for sensor type detection, reducing configuration time by 30% compared to manual setups.

Predictive Maintenance Integration

By integrating with ABB’s Ability™ analytics platform, the 500TRM02 1MRB150011R1 enables predictive maintenance through machine learning. It can detect anomalies like rising bearing temperatures (indicating lubrication issues) or uneven stator phase temperatures (signaling winding faults), triggering alerts via email or SCADA systems. In a food processing plant, this proactive approach prevents costly downtime during peak production cycles by scheduling maintenance during planned outages.

Compact and Rugged Design

Designed for harsh industrial environments, the module’s conformal-coated PCB and reinforced housing resist moisture, dust, and vibration—key advantages in mining or offshore applications. Its hot-swappable design allows technicians to replace faulty units without powering down the system, while the front-panel LED indicators provide instant status updates (green for normal, amber for alarm, red for trip).

500TRM02 1MRB150011R1

Application Field

The ABB 500TRM02 1MRB150011R1 is essential in industries where motor reliability is non-negotiable:

- Manufacturing: Monitors motors in CNC machines, robotic arms, and conveyor systems. In an automotive assembly line, it ensures that paint shop fans operate within thermal limits, preventing overheating that could compromise paint quality.

- Energy and Utilities: Protects pumps, compressors, and generators in power plants and substations. For instance, in a wind farm, the module tracks gearbox bearing temperatures in real time, enabling timely lubrication to avoid catastrophic failures.

- Process Industries: Used in chemical reactors, mixers, and distillation columns to prevent thermal runaway. In a petrochemical plant, it safeguards high-power agitators by shutting down motors when stator temperatures exceed safe limits, minimizing the risk of hazardous leaks.

- Water and Wastewater: Controls pumps in lift stations and treatment plants, where motor overheating from clogged pipes is a common issue. The module’s thermal overload protection ensures continuous operation during heavy rain events or high inflow periods.

Related Products

- ABB 500TRM01 1MRB150010R1: A basic thermal monitoring module with 3 sensor channels, suitable for single-phase motors or simple applications.

- ABB 1MRB150012R1: An upgraded variant with built-in energy metering, ideal for high-efficiency motor systems requiring both thermal and power consumption tracking.

- ABB PM510: A motor protection circuit breaker that pairs with the 500TRM02 for comprehensive overload and short-circuit protection.

- ABB CI522: A Profibus DP interface module, enhancing the 500TRM02’s connectivity in large-scale DCS networks.

- ABB TA541: A terminal block for secure sensor wiring, compatible with the module’s PTC/NTC input channels.

Installation and Maintenance

Pre-installation preparation: Mount the 500TRM02 1MRB150011R1 on a DIN rail in the control panel, ensuring at least 25 mm of clearance for heat dissipation. Connect PTC/NTC/RTD sensors to the TA541 terminal block using shielded twisted-pair cables, following the color-coded wiring diagram in the manual. Configure sensor types, trip thresholds, and communication parameters via ABB’s Drive Composer Pro software, verifying compatibility with the motor’s thermal rating.

Maintenance recommendations: Inspect sensor connections quarterly for loose terminals or corrosion, especially in high-humidity environments like food processing plants. Use the module’s web interface to review temperature trend reports monthly, identifying patterns such as gradual increases in winding temperature that may indicate aging insulation. Update firmware annually to access new sensor compatibility or security features, and perform a functional test of alarm/trip functions every six months using a simulated overheat scenario.

Product Guarantee

ABB stands behind the 500TRM02 1MRB150011R1 with a 3-year warranty, covering defects in materials and workmanship. ABB’s global technical support team provides 24/7 assistance for configuration, troubleshooting, and remote diagnostics, ensuring minimal disruption to operations. The module’s compliance with IEC and UL standards, combined with rigorous testing (e.g., 10,000-cycle thermal stress tests), guarantees long-term reliability. For customers in regulated industries, ABB offers Validation Services to ensure the module meets specific safety and compliance requirements, providing peace of mind in mission-critical applications.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.