Description

Product Overview

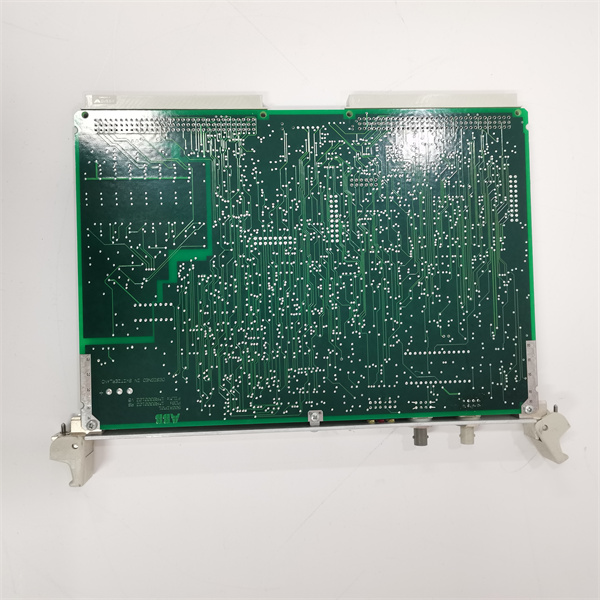

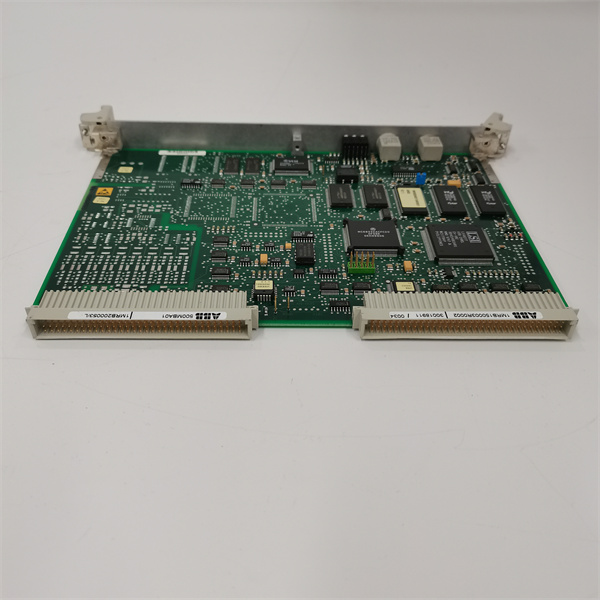

The ABB 500MBA01 1MRB150003R0002 1MRB200053/L is a high-precision motor breaker and monitoring system designed for industrial applications requiring robust protection and advanced diagnostics for low-voltage motors. As part of ABB’s Motor Control and Protection (MCP) portfolio, this solution combines a motor circuit breaker with intelligent monitoring capabilities to safeguard motors from overloads, short circuits, and abnormal operating conditions. The 500MBA01 serves as the core breaker unit, while the 1MRB150003R0002 and 1MRB200053/L modules provide motor health analysis and communication interfaces, making it ideal for manufacturing, food & beverage, and water treatment industries where motor reliability is critical.

Engineered for seamless integration into ABB’s AC 500 PLC system, the 500MBA01 1MRB150003R0002 1MRB200053/L offers real-time monitoring of parameters like stator current, power factor, and thermal status. Its electronic overload protection replaces traditional thermal relays, providing precise trip characteristics and adaptive cooling curves for different motor types. The 1MRB200053/L communication module supports protocols like Modbus RTU and Profibus DP, enabling remote monitoring via SCADA systems or cloud platforms. Positioned as a future-proof solution, this system reduces unplanned downtime by up to 40% through predictive maintenance based on motor health trends.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 500MBA01 1MRB150003R0002 1MRB200053/L |

| Manufacturer | ABB |

| Product Type | Motor Breaker with Integrated Monitoring |

| Voltage Rating | 400 V AC (3-phase), 24 V DC (control) |

| Current Rating | 0–100 A (adjustable, via 1MRB150003R0002) |

| Protection Functions | Overload, short circuit, phase unbalance, 堵转 (locked rotor) |

| Communication Protocols | Modbus RTU, Profibus DP, Ethernet/IP (via 1MRB200053/L) |

| Thermal Monitoring | Stator temperature via PTC sensors |

| Dimensions (W×H×D) | 125 mm × 100 mm × 85 mm (breaker unit) |

| Mounting Method | DIN rail or panel mounting |

| Certification | CE, UL, IEC 60947-2, RoHS |

| Response Time | <10 ms (fault detection to trip) |

500MBA01 1MRB150003R0002 1MRB200053/L

Main Features and Advantages

Advanced Motor Protection

The 500MBA01 ensures rapid fault response with its high-speed magnetic trip unit, interrupting short circuits within milliseconds to prevent damage to motors and connected equipment. The 1MRB150003R0002 module adds adaptive overload protection, using thermal modeling to simulate motor winding temperature and adjust trip thresholds based on load profiles. For example, in a wastewater pump system, the system can differentiate between normal startup inrush and a true overload, avoiding unnecessary trips during pump priming.

Intelligent Health Monitoring

The 1MRB200053/L module enables predictive maintenance by analyzing motor performance trends, such as increasing current harmonics (indicating bearing wear) or declining power factor (signaling stator winding degradation). Real-time data is visualized via ABB’s Drive Composer Pro software, with configurable alarms for parameters like unbalance (>10%) or voltage fluctuations (>±5%). In a food processing plant, this feature can detect early signs of motor fatigue in conveyor systems, scheduling maintenance during planned downtime rather than causing production delays.

Compact and Flexible Design

With a footprint of just 125 mm width, the 500MBA01 1MRB150003R0002 1MRB200053/L fits into space-constrained control panels, ideal for retrofitting older systems. The modular design allows easy replacement of individual components (e.g., breaker, monitoring module) without rewiring, while the plug-and-play Profibus DP interface reduces commissioning time by 30%. The system also supports dual-channel operation, enabling redundant control in critical applications like pharmaceutical mixing tanks.

500MBA01 1MRB150003R0002 1MRB200053/L

Application Field

The ABB 500MBA01 1MRB150003R0002 1MRB200053/L excels in industries reliant on motor-driven processes:

- Manufacturing: Protects motors in packaging lines, CNC machines, and robotic systems. In an automotive assembly plant, the system monitors conveyor motor current to detect jammed parts, triggering an immediate stop to prevent equipment damage.

- Water and Wastewater: Controls pumps and agitators in treatment plants, with 堵转 protection preventing motor burnout from clogged pipelines. The system’s wide temperature range (-25°C to +60°C) ensures reliability in outdoor pump stations.

- Food and Beverage: Used in mixers, sterilizers, and bottling equipment, where hygienic design and fault-free operation are critical. The 1MRB200053/L module’s Ethernet connectivity allows integration with plant-wide MES systems for real-time OEE tracking.

- HVAC Systems: Manages fan and chiller motors in commercial buildings, optimizing energy usage through real-time power consumption monitoring. The system’s soft start feature reduces inrush current, extending motor and mechanical component lifespan.

Related Products

- ABB 500MCC01: A motor contactor module for non-protective switching, often paired with the 500MBA01 for complete motor control.

- ABB 1MRB150010R0001: An upgraded monitoring module with built-in energy metering, suitable for high-efficiency motor applications.

- ABB CI522: A Profibus DP interface module for enhanced communication scalability in large control systems.

- ABB PM590: A variable speed drive, compatible with the 500MBA01 for integrated motor control and protection.

- ABB TA541: A terminal block for secure field wiring, used with the 1MRB150003R0002 to connect PTC sensors and control signals.

Installation and Maintenance

Pre-installation preparation: Mount the 500MBA01 on a DIN rail in the control panel, ensuring proper spacing for heat dissipation. Connect motor power cables to the breaker’s 进线端 (line side) and load 端 (load side), using stranded copper wires (max. 35 mm²). Install the 1MRB150003R0002 and 1MRB200053/L modules in adjacent slots, linking them via the backplane for power and data. Configure motor parameters (e.g., full-load current, number of poles) using Drive Composer Pro, and validate trip settings with a simulated overload test.

Maintenance recommendations: Inspect the breaker’s contact tips quarterly for signs of arcing or wear, replacing them if pitting is detected. Monitor motor health data via the 1MRB200053/L module’s web interface, paying attention to trends in vibration metrics (if paired with external sensors). Update firmware annually to access new protection algorithms or communication protocols. In dusty environments, clean the module’s vents with compressed air every six months to maintain optimal thermal performance.

Product Guarantee

ABB stands behind the 500MBA01 1MRB150003R0002 1MRB200053/L with a 3-year warranty, covering defects in materials and workmanship. ABB’s global service network provides 24/7 technical support, including remote parameter tuning and fault analysis. The system’s compliance with IEC 60947-2 and RoHS standards ensures compatibility with international safety and environmental regulations. For critical applications, ABB offers Premier Support plans, including annual onsite inspections and priority access to replacement parts, minimizing downtime and maximizing operational efficiency. By combining robust protection, intelligent monitoring, and ease of integration, the 500MBA01 1MRB150003R0002 1MRB200053/L delivers unmatched value for industrial motor control.

Shanxi Runsheng Import and Export Co., LTD. Our main products: FOXBORO, EMERSON, TRICONEX, XYCOM, BENTLY, ROCKWELL, ABB, GE, Allen-Bradley, YOKOGAWA, HONEYWELL, RELIANCE, SCHNEIDER, MODICON, Westin ghouse, WOODWARD, Motorola, Rexroth, SEW, Denkon. And other major brands of DCS, PLC, robot, large servo four system spare parts. Other automation spare parts sales and technical support. Please visit our website www.rsmodules.com or contact us at +86 15383514022 and we will be happy to serve you.