Description

Product Overview

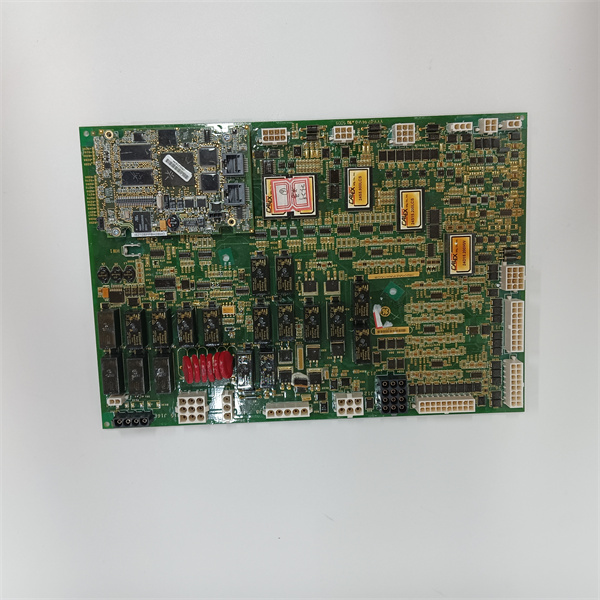

The GE 369 – HI – R – M – 0 – D – 0 – E is a sophisticated motor management relay belonging to GE’s esteemed Multilin 369 series. In the realm of industrial automation, it serves as a crucial safeguard for AC motors, shielding them from a wide gamut of electrical malfunctions and abnormal operating conditions. This microprocessor – based relay is designed to be a one – stop solution for motor protection and monitoring in various industrial setups.

It comes packed with an array of functions that ensure the seamless operation of motors. With features like under – voltage automatic restart, reverse power protection, and starter fault detection, it acts as a vigilant guardian for motors. The GE 369 – HI – R – M – 0 – D – 0 – E also monitors key parameters such as voltage, current, power, frequency, and energy. By keeping a close eye on these values, it can promptly detect any deviations and trigger appropriate protection actions. Additionally, its event recording function logs all significant events like faults and alarms, which is invaluable for post – mortem analysis and troubleshooting, making it an essential component in maintaining the overall efficiency and reliability of industrial motor – driven systems.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | 369 – HI – R – M – 0 – D – 0 – E |

| Manufacturer | General Electric |

| Product Type | Motor Management Relay |

| Input Voltage Range | 50 – 300 VDC / 60 – 265 VAC |

| Protection Functions | Under – voltage automatic restart, reverse power protection, starter fault detection, etc. |

| Monitoring Parameters | Voltage, current, power, frequency, energy |

| Communication Protocols | Compatible with multiple (e.g., Modbus, DNP 3, IEC 61850) |

| Event Recording Capacity | Records a significant number of events (e.g., last 512 events) |

| Operating Temperature | – 40 °C to + 60 °C |

| Storage Temperature | – 40 °C to + 80 °C |

| Weight | Approximately [X] kg (specify in product manual) |

| Dimensions | [Specify height, width, depth in product manual] |

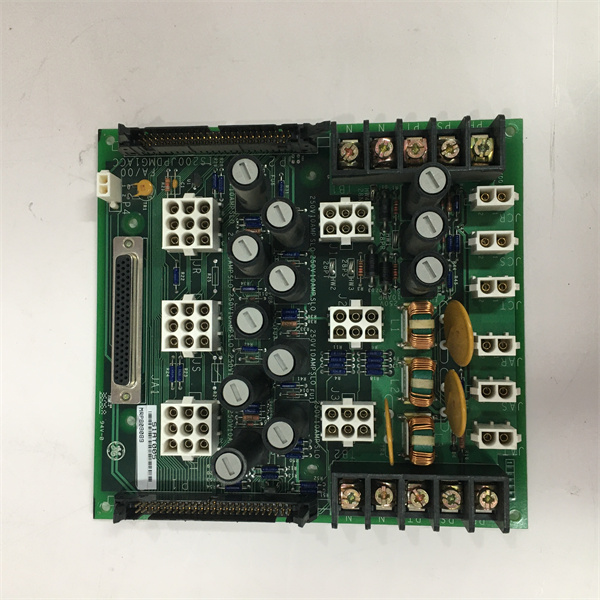

IS200JPDMG1ACC S1AT005

Main Features and Advantages

Comprehensive Protection: The GE 369 – HI – R – M – 0 – D – 0 – E offers an extensive range of protection functions. Its ability to handle under – voltage automatic restart ensures that motors can resume operation smoothly once the power supply stabilizes. Reverse power protection safeguards motors from damage caused by incorrect power flow. Starter fault detection helps in quickly identifying and rectifying issues related to motor starters, reducing downtime.

Accurate Monitoring: With its capacity to monitor crucial parameters like voltage, current, power, frequency, and energy, this relay provides real – time insights into motor performance. Precise monitoring allows for early detection of potential problems. For example, if the current drawn by a motor exceeds the normal range, it could indicate an impending mechanical issue, and the relay can trigger an alarm or take protective action.

Event Recording and Analysis: The detailed event recording feature of the GE 369 – HI – R – M – 0 – D – 0 – E is a boon for maintenance teams. It logs all fault events, alarms, and other significant occurrences. This data can be analyzed to understand the root cause of motor failures, enabling preventive maintenance and improving overall system reliability.

Flexible Communication: It is compatible with a variety of communication protocols such as Modbus, DNP 3, and IEC 61850. This flexibility allows for seamless integration into different industrial control systems, facilitating remote monitoring and control. Operators can access motor data from a central control room, enhancing operational efficiency.

Accurate Monitoring: With its capacity to monitor crucial parameters like voltage, current, power, frequency, and energy, this relay provides real – time insights into motor performance. Precise monitoring allows for early detection of potential problems. For example, if the current drawn by a motor exceeds the normal range, it could indicate an impending mechanical issue, and the relay can trigger an alarm or take protective action.

Event Recording and Analysis: The detailed event recording feature of the GE 369 – HI – R – M – 0 – D – 0 – E is a boon for maintenance teams. It logs all fault events, alarms, and other significant occurrences. This data can be analyzed to understand the root cause of motor failures, enabling preventive maintenance and improving overall system reliability.

Flexible Communication: It is compatible with a variety of communication protocols such as Modbus, DNP 3, and IEC 61850. This flexibility allows for seamless integration into different industrial control systems, facilitating remote monitoring and control. Operators can access motor data from a central control room, enhancing operational efficiency.

Application Field

In industrial manufacturing plants, the GE 369 – HI – R – M – 0 – D – 0 – E is widely deployed to protect and monitor motors that drive conveyor belts, pumps, and various machinery. For instance, in a large – scale food processing plant, motors powering conveyor belts that transport food products need to operate continuously without interruption. The relay ensures that these motors are protected from electrical faults and monitored for optimal performance, preventing any disruption in the production line.

In the mining industry, where motors are used in equipment like crushers, conveyors, and ventilation systems, the GE 369 – HI – R – M – 0 – D – 0 – E plays a critical role. Mines often operate in harsh environments with high levels of dust and vibration, which can put additional stress on motors. The relay’s robust protection and monitoring capabilities help in maintaining the reliability of these motors, ensuring the smooth operation of mining activities.

Power generation facilities also rely on this relay for motors in their systems. Motors in power plants are used for functions such as cooling water circulation, coal handling, and generator cooling. The GE 369 – HI – R – M – 0 – D – 0 – E ensures that these motors operate efficiently, protecting them from faults and contributing to the stable generation of electricity.

In the mining industry, where motors are used in equipment like crushers, conveyors, and ventilation systems, the GE 369 – HI – R – M – 0 – D – 0 – E plays a critical role. Mines often operate in harsh environments with high levels of dust and vibration, which can put additional stress on motors. The relay’s robust protection and monitoring capabilities help in maintaining the reliability of these motors, ensuring the smooth operation of mining activities.

Power generation facilities also rely on this relay for motors in their systems. Motors in power plants are used for functions such as cooling water circulation, coal handling, and generator cooling. The GE 369 – HI – R – M – 0 – D – 0 – E ensures that these motors operate efficiently, protecting them from faults and contributing to the stable generation of electricity.

Related Products

- GE 369 – HI – R – M – 0 – 0 – 0 – E: Similar to the GE 369 – HI – R – M – 0 – D – 0 – E, it is a motor management relay in the 369 series. However, it may have different configurations in terms of input/output options or specific protection and monitoring features, offering an alternative for applications with slightly different requirements.

- GE 369 – HI – R – M – 0 – 0: This model also belongs to the 369 motor protection series. It comes with optional metering functions and 12 RTD inputs, which can be useful for applications that require more in – depth temperature monitoring of the motor system, as compared to the GE 369 – HI – R – M – 0 – D – 0 – E which may have different sensor input arrangements.

- GE Multilin 369 General Model: The base model of the series, which provides the fundamental motor protection and monitoring functions. The GE 369 – HI – R – M – 0 – D – 0 – E is an advanced version with additional features and specific configurations tailored for more complex industrial applications.

- GE Motor Protection Relays from Other Series: For example, some relays from different GE series may offer simpler protection functions at a lower cost. They can be considered for applications where the requirements are not as demanding as those suitable for the GE 369 – HI – R – M – 0 – D – 0 – E, such as in small – scale industrial setups or less critical motor applications.

- Communication Modules Compatible with 369 Series: These modules can enhance the communication capabilities of the GE 369 – HI – R – M – 0 – D – 0 – E. They can enable connection to different types of industrial networks or improve the speed and reliability of data transfer, expanding the relay’s functionality in network – centric control systems.

Installation and Maintenance

Pre – installation preparation: Before installing the GE 369 – HI – R – M – 0 – D – 0 – E, ensure that the power supply voltage falls within the specified 50 – 300 VDC / 60 – 265 VAC range. Check the installation area for any sources of electromagnetic interference that could affect the relay’s performance. The physical space should be sufficient to accommodate the relay, considering its dimensions. Inspect the relay for any visible damage during transit, such as cracks in the casing or loose connections.

Maintenance recommendations: Regularly monitor the GE 369 – HI – R – M – 0 – D – 0 – E for any signs of overheating, like discoloration of the casing or unusual smells. Check the event logs periodically to identify any recurring issues or early warning signs of motor problems. Clean the relay to remove dust and debris, especially in environments with high particulate matter. If any faults are detected, refer to the product manual for troubleshooting steps. For complex issues, contact GE’s technical support for expert assistance to ensure the continued reliable operation of the relay and the motors it protects.

Maintenance recommendations: Regularly monitor the GE 369 – HI – R – M – 0 – D – 0 – E for any signs of overheating, like discoloration of the casing or unusual smells. Check the event logs periodically to identify any recurring issues or early warning signs of motor problems. Clean the relay to remove dust and debris, especially in environments with high particulate matter. If any faults are detected, refer to the product manual for troubleshooting steps. For complex issues, contact GE’s technical support for expert assistance to ensure the continued reliable operation of the relay and the motors it protects.

Product Guarantee

GE stands firmly behind the quality of the GE 369 – HI – R – M – 0 – D – 0 – E motor management relay. It typically comes with a standard one – year warranty, covering defects in materials and workmanship under normal usage conditions. In the unlikely event that any issues arise within this period, GE will provide repair or replacement services free of charge. Their dedicated technical support team is available around the clock to offer assistance. Whether it’s helping with installation guidance, answering questions regarding configuration, or providing troubleshooting advice, GE’s support ensures that customers can rely on the GE 369 – HI – R – M – 0 – D – 0 – E for their motor protection and monitoring needs. This commitment to quality and customer satisfaction reflects GE’s confidence in the product’s durability and performance in industrial settings.