Description

Product Overview

The GE SR750 – P5 – G1 – S1 – HI – A20 – R is a high – performance feeder management relay from General Electric, designed to play a pivotal role in the control and safeguarding of distribution systems. As part of GE’s 750/760 feeder protection system family, this relay is engineered to meet the complex demands of modern industrial and utility power distribution setups.

It is equipped with 5A phase current inputs and 5A zero sequence inputs, enabling it to accurately monitor the electrical parameters of power distribution lines. The eight 4 – 20 mA analog outputs provide flexibility for connecting to other control and monitoring devices, facilitating seamless integration within a larger automation network. This GE SR750 – P5 – G1 – S1 – HI – A20 – R relay is not only about measurement but also about protection. It offers a wide range of protective functions, ensuring the safety and reliability of the distribution feeders it is connected to, thus enhancing the overall stability of the power distribution infrastructure.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | SR750 – P5 – G1 – S1 – HI – A20 – R |

| Manufacturer | General Electric |

| Product Type | Feeder Management Relay |

| Phase Current Input | 5A |

| Zero Sequence Input | 5A |

| Analog Outputs | Eight 4 – 20 mA |

| Power Supply | 88 – 300 VDC, 70 – 265 VAC @ 48 – 62 Hz |

| Operating Humidity | Up to 90% non – condensing |

| Frequency Range | 25 – 60 Hz nominal |

| Overvoltage Pickup Level | 0 to 1.25 × vt in steps of 0.01 |

| Relay Dimensions | Approx. 18 cm W, 16.5 cm L, 21.5 cm H |

| Waveform Capture Channels | 4 currents, 3 voltages, 14 logic input states and 8 output relays |

| Communication Protocols | Modbus RTU, DNP 3.0 |

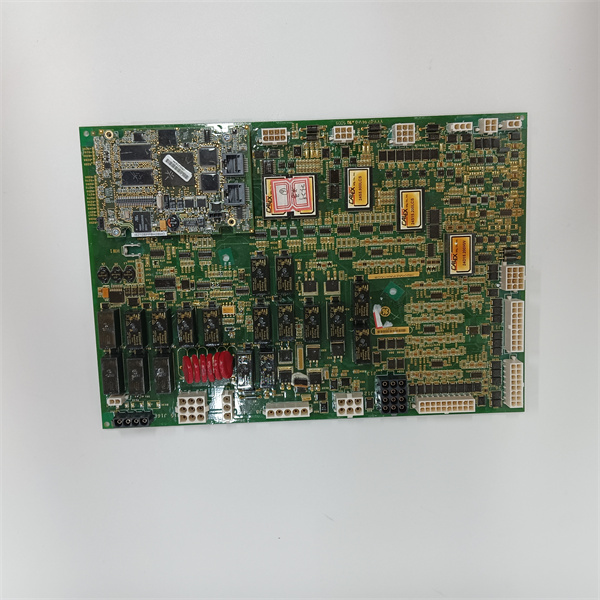

IS200AEPAH1ACB

Main Features and Advantages

Precise Parameter Monitoring

The GE SR750 – P5 – G1 – S1 – HI – A20 – R excels in accurately measuring phase currents and voltages. With its 5A phase current and 5A zero sequence current inputs, it can detect even the slightest fluctuations in the power distribution system. This precision is crucial for maintaining the reliable operation of the system, as it allows for early detection of potential issues such as overcurrents or imbalances, which could otherwise lead to equipment damage or power outages.

Robust Protective Functions

This relay comes with an array of protective functions. Overcurrent protection safeguards against excessive current flow that could harm equipment or cause fires. Under/over frequency protection ensures that the power system operates within the acceptable frequency range, preventing problems associated with abnormal frequencies. Ground fault protection is also included, which is vital for detecting and dealing with faults in the grounding system, enhancing the overall safety of the electrical installation.

Versatile Communication Capabilities

Featuring communication protocols like Modbus RTU and DNP 3.0, the GE SR750 – P5 – G1 – S1 – HI – A20 – R can easily integrate with various industrial control systems. This seamless connectivity enables real – time data transfer between the relay and other devices in the network. Operators can remotely monitor and control the relay, receive alerts about system anomalies, and access historical data for analysis, all of which contribute to more efficient power distribution management.

Compact and Easy – to – Install Design

Its compact dimensions make the GE SR750 – P5 – G1 – S1 – HI – A20 – R suitable for installation in standard 19 – inch panels. This design not only saves valuable space in control cabinets but also simplifies the installation process. Whether it’s a new power distribution project or an upgrade of an existing system, the relay can be quickly and easily integrated, reducing installation time and costs.

Application Field

Industrial Power Distribution

In industrial settings, such as manufacturing plants, the GE SR750 – P5 – G1 – S1 – HI – A20 – R is used to manage and protect the power distribution feeders. It ensures that the high – power equipment, like large motors and industrial machinery, receive a stable and safe power supply. By constantly monitoring the electrical parameters and providing protection against faults, it helps to minimize production downtime caused by power – related issues, thus maintaining high productivity levels.

Utility Power Grids

Power utilities rely on the GE SR750 – P5 – G1 – S1 – HI – A20 – R to safeguard and control the distribution feeders within their grids. It plays a key role in detecting and responding to faults in the medium – voltage distribution network. For example, in the event of a short – circuit or an overload, the relay can quickly isolate the affected section of the grid, preventing the spread of the fault and ensuring the continuous supply of power to other customers.

Commercial Buildings

In large commercial buildings, such as shopping malls or office complexes, the GE SR750 – P5 – G1 – S1 – HI – A20 – R is used to manage the power distribution system. It monitors the power consumption of different areas within the building and provides protection against electrical faults. This helps building managers to ensure the reliable operation of essential services like lighting, heating, ventilation, and air – conditioning systems, enhancing the comfort and safety of building occupants.

Related Products

SR750 – P1 – G1 – S1 – HI – A20 – R

Similar to the GE SR750 – P5 – G1 – S1 – HI – A20 – R, it is also a feeder management relay. However, it may have different current input ratings or a more basic feature set, making it suitable for applications with lower power requirements or less complex monitoring needs.

489 – P5 – HI – A20

This is a motor management relay in GE’s product line. It is designed specifically for motor – related applications, while the GE SR750 – P5 – G1 – S1 – HI – A20 – R focuses on feeder management. But in some industrial setups, they may be used in tandem, with the 489 – P5 – HI – A20 controlling motors and the SR750 – P5 – G1 – S1 – HI – A20 – R managing the power feeders that supply these motors.

489 – P5 – HI – A20 – E

An enhanced version of the 489 – P5 – HI – A20 motor management relay. It likely has additional features such as an enhanced display or better environmental resistance. It can be used in scenarios where more advanced motor management functions are required, and like the 489 – P5 – HI – A20, may interact with the GE SR750 – P5 – G1 – S1 – HI – A20 – R in a larger power management system.

489 – P5 – LO – A20

Another motor management relay with a different control power unit. It may be used in applications where cost – effectiveness or specific power – control requirements are a priority. In an industrial power setup, it could work in combination with the GE SR750 – P5 – G1 – S1 – HI – A20 – R to manage different aspects of the power and motor control system.

SR750 – P5 – G5 – S5 – HI – A20 – R

This is also a feeder management relay, but with potentially different input/output configurations or enhanced capabilities in specific areas such as more advanced waveform capture or additional communication options. It can be chosen for applications that demand a higher level of performance or more specific monitoring and control features compared to the GE SR750 – P5 – G1 – S1 – HI – A20 – R.

Installation and Maintenance

Pre – installation preparation: Before installing the GE SR750 – P5 – G1 – S1 – HI – A20 – R relay, ensure that the power supply to the relevant electrical system is turned off to avoid any electrical hazards. Check the physical dimensions of the relay to confirm that it will fit into the intended 19 – inch panel space. Verify that the power supply voltage and frequency match the requirements of the GE SR750 – P5 – G1 – S1 – HI – A20 – R, which are 88 – 300 VDC, 70 – 265 VAC @ 48 – 62 Hz. Inspect the connection ports for any signs of damage or dirt and clean them if necessary. Also, make sure that all the necessary wiring and mounting hardware are in good condition and of the correct type.

Maintenance recommendations: Regularly clean the GE SR750 – P5 – G1 – S1 – HI – A20 – R to remove dust and debris, as these can accumulate over time and affect its performance, especially in environments with high levels of particulate matter. Periodically check the relay’s input and output connections to ensure they are secure and free from corrosion. Monitor the electrical parameters that the relay measures, such as phase currents and voltages, to detect any abnormal trends. If any issues are detected, refer to the product manual for troubleshooting steps. Replace any worn – out components promptly to maintain the relay’s reliability and ensure continued protection of the power distribution system.

Product Guarantee

General Electric stands firmly behind the quality of the GE SR750 – P5 – G1 – S1 – HI – A20 – R feeder management relay. The product undergoes rigorous quality control during manufacturing to meet high – industry standards. GE offers a standard 1 – year warranty for the GE SR750 – P5 – G1 – S1 – HI – A20 – R. In case of any manufacturing defects within this period, GE will provide repair or replacement services free of charge. Their global network of technical support teams is available to assist customers with installation, configuration, and troubleshooting. Whether it’s answering questions about the relay’s operation or providing guidance on maintenance, customers can rely on GE’s expertise. This guarantee reflects GE’s confidence in the product and its commitment to providing reliable power distribution control and protection solutions, giving customers peace of mind when using the GE SR750 – P5 – G1 – S1 – HI – A20 – R in their critical power management applications.