Description

Product Overview

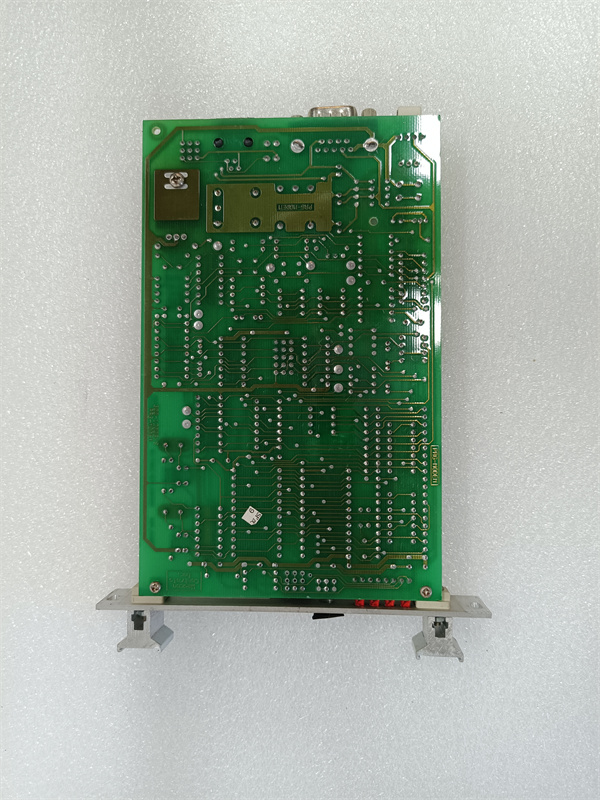

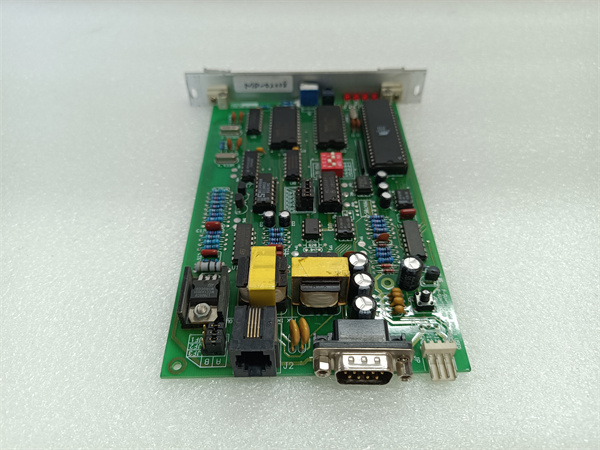

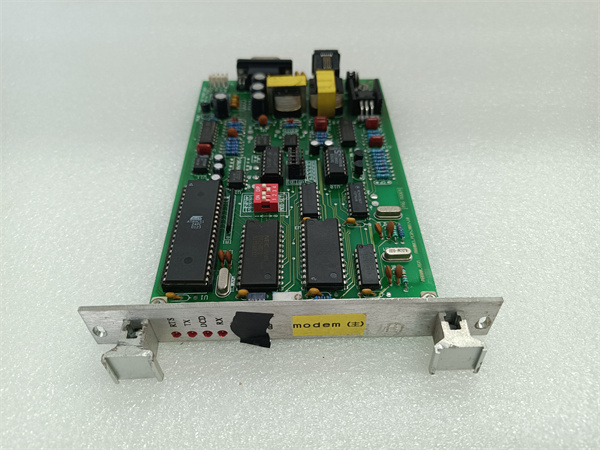

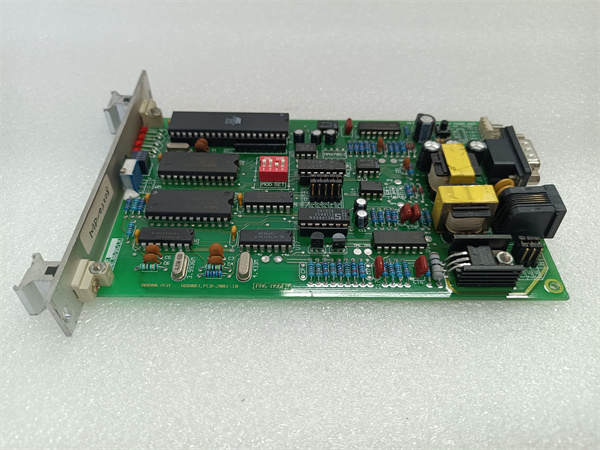

The GE PRG – MODEM is a high – performance industrial communication modem crafted by General Electric, a globally recognized leader in industrial automation. Engineered for industrial automation and control systems, it serves as a linchpin for seamless data transmission. This modem enables remote monitoring and control of industrial equipment, collecting data from sensors and other devices, and even programming industrial controllers.

The PRG – MODEM is part of GE’s comprehensive portfolio of industrial communication solutions. It is designed to work within complex industrial ecosystems, integrating with other GE components and third – party devices. Its core function is to provide a reliable connection over long distances, making it suitable for applications where real – time data transfer is crucial, such as in large – scale manufacturing plants or remote industrial sites. By facilitating smooth communication, it enhances the overall efficiency and reliability of industrial operations, ensuring that all components of an automation system can interact effectively.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Product Model | PRG – MODEM |

| Manufacturer | General Electric |

| Product Type | Communication Modem |

| Communication Protocols | RS – 232, RS – 485, Modbus, Ethernet / IP, DNP 3 |

| Data Rate | Up to 56 kbps |

| Power Supply | 9 – 30 VDC |

| Operating Temperature Range | – 40 °C to + 85 °C |

| Communication Distance | Up to 10 km (with appropriate cabling) |

| Power Consumption | Less than 5W |

| Mounting Options | Panel mount or DIN rail mount |

| Dimensions | 160 x 90 x 30 mm |

| Weight | 0.5 kg |

| Compliance Standards | CE, FCC, ROHS, IEC 61850, IEEE 802.3 |

GE PRG-MODEM

Main Features and Advantages

Reliable and stable

The GE PRG – MODEM features a rugged construction, allowing it to endure harsh industrial environments. With an operating temperature range from – 40 °C to + 85 °C, it can function consistently even in extreme conditions, ensuring stable data transmission at all times.

Versatile communication

It supports multiple communication protocols and interfaces, including RS – 232, RS – 485, and Ethernet. This versatility enables easy integration with a wide variety of industrial devices and systems, providing flexible communication options to meet diverse application needs.

High – speed data transmission

Leveraging advanced modulation techniques, the PRG – MODEM can achieve data transfer speeds of up to 56 kbps. This high – speed performance ensures efficient and timely data transmission for remote monitoring and control applications, enabling quick responses to any changes in the industrial process.

User – friendly

The modem has a straightforward configuration process and a user – friendly interface. Requiring only a basic operating voltage within the 9 – 30 VDC range, it can be set up rapidly without the need for complex tools or extensive training, saving users both time and effort.

GE PRG-MODEM

Application Field

In power plants, the GE PRG – MODEM is extensively used for remote monitoring and control of power generation equipment. Operators can manage and maintain the plant’s operations more efficiently, receiving real – time data on equipment performance and quickly addressing any potential issues.

Manufacturing facilities benefit from the PRG – MODEM by using it to monitor production lines. It collects data from sensors placed throughout the production process, allowing for optimization of production flow. For example, it can detect bottlenecks in the assembly line and enable adjustments to improve overall productivity.

The oil and gas industry also relies on the PRG – MODEM for remote monitoring of wells and pipelines. It ensures the safety and reliability of operations by continuously transmitting data on pressure, temperature, and flow rates from remote field devices to the central control station.

In process automation systems, the PRG – MODEM plays a crucial role in enabling seamless communication between different components. It helps in coordinating the operation of various machines and devices, ensuring the smooth running of complex industrial processes.

Related Products

- GE FANUC IC697CMM731: A communication module in the GE FANUC series. It can be used in combination with the PRG – MODEM to expand the communication capabilities of the overall system, providing additional interfaces and protocol support.

- GE IC698CMM002: Another communication – related product. It can work in tandem with the PRG – MODEM to offer different communication interfaces and protocols tailored to specific industrial applications, enhancing the flexibility of the industrial communication network.

- GE Power Supply Modules (e.g., GE IC697PWR710): These power supply modules are designed to provide the necessary power for the PRG – MODEM and other related devices in the industrial control system. A stable power supply is essential for the reliable operation of the modem.

- GE Ethernet Switches (e.g., GE IC695ETM001): They can be used together with the PRG – MODEM to establish a reliable Ethernet – based communication network in industrial settings. The switches help in managing and directing data traffic between different devices connected to the network.

- GE I/O Modules (e.g., GE IC697MDL740): These I/O modules work in conjunction with the PRG – MODEM to enable data exchange between the control system and field devices. They expand the input and output capabilities of the system, allowing for connection to a wider range of sensors and actuators.

Installation and Maintenance

Pre – installation preparation: Before installing the GE PRG – MODEM, verify that the installation environment meets the requirements. Check the power supply voltage to ensure it falls within the 9 – 30 VDC range. Inspect the communication interfaces to confirm they are clean and undamaged. Select an installation location based on the available mounting options (panel mount or DIN rail mount), and ensure it is away from sources of electromagnetic interference.

Maintenance recommendations: Regularly monitor the operating status of the GE PRG – MODEM by checking the power indicator and communication status lights. Clean the device periodically to prevent dust accumulation, as this can affect performance. Stay updated on software updates from GE and install them in a timely manner to ensure the modem operates with the latest features and bug fixes. In case of malfunctions, consult the product manual for troubleshooting steps or reach out to the GE technical support team.

Product Guarantee

General Electric stands firmly behind the quality of the GE PRG – MODEM. Through rigorous quality control measures, GE ensures that each unit meets the highest standards. The product comes with a one – year warranty. During this period, if any defects are found due to manufacturing issues, GE will repair or replace the PRG – MODEM free of charge. Moreover, GE provides professional technical support. Their team of experts is available to assist customers with any questions regarding installation, configuration, or operation. This support ensures that the PRG – MODEM functions optimally and that customers’ industrial automation systems run smoothly.